1

Contents

1. Introduction

Safety … … … … … … … … … … … … … … … … … … … … … … … … 2

About your machine … … … … … … … … … … … … … … … … … … … 3

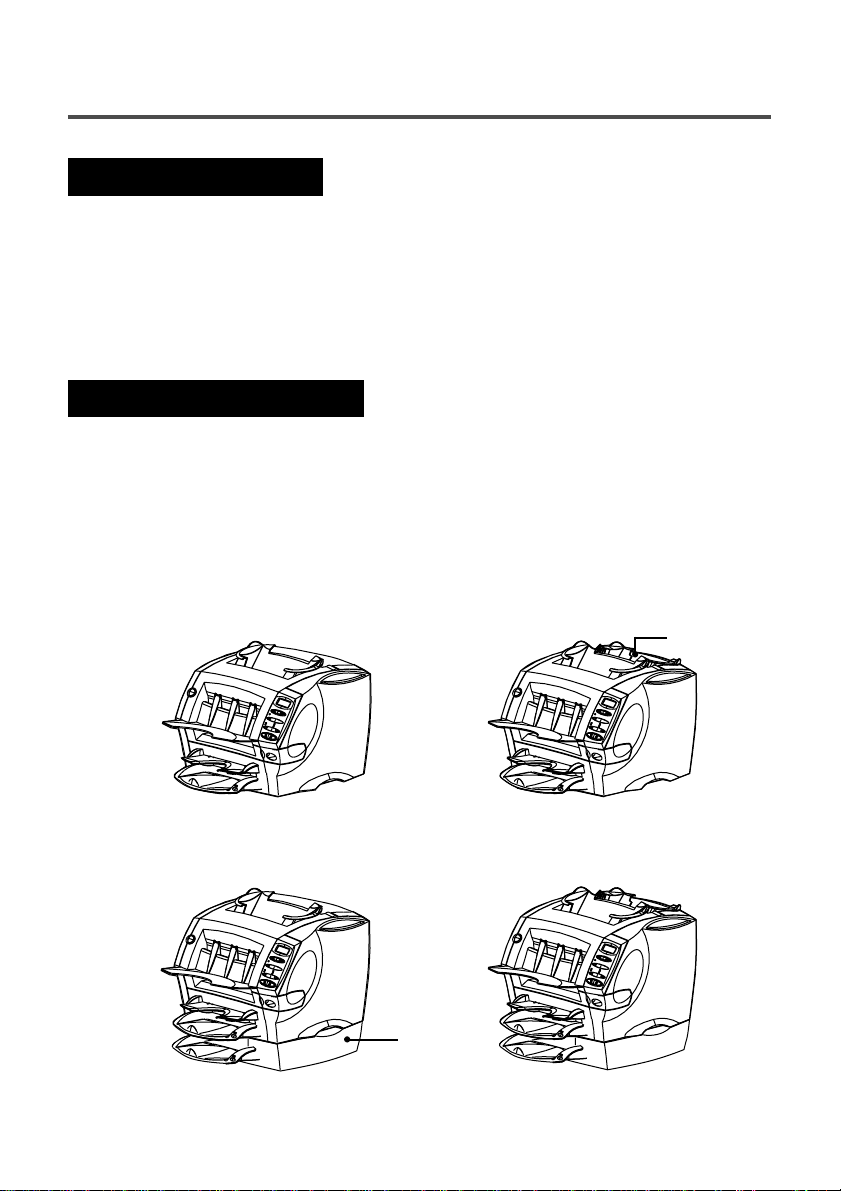

Machine Configurations … … … … … … … … … … … … … … … … … … 3

Machine Identification … … … … … … … … … … … … … … … … … … … 4

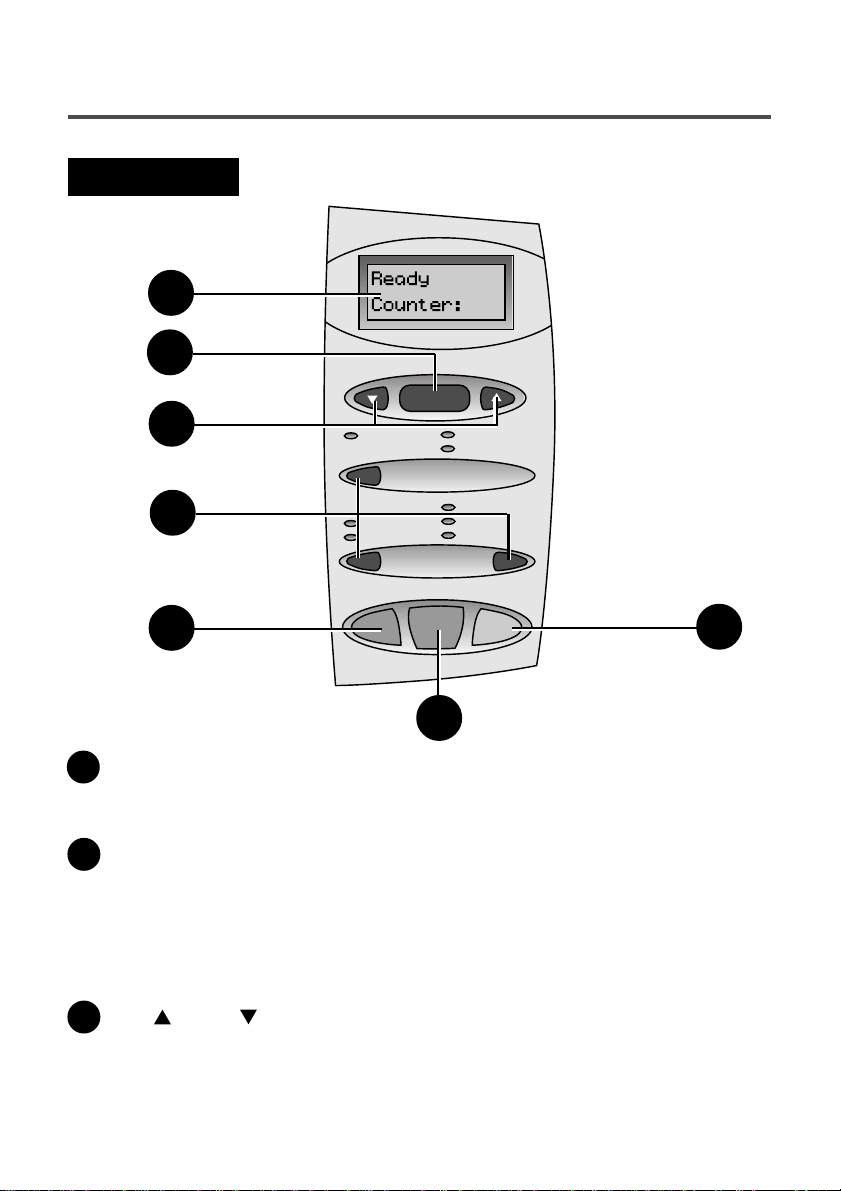

The Controls … … … … … … … … … … … … … … … … … … … … … … 6

2. Preparing and Loading

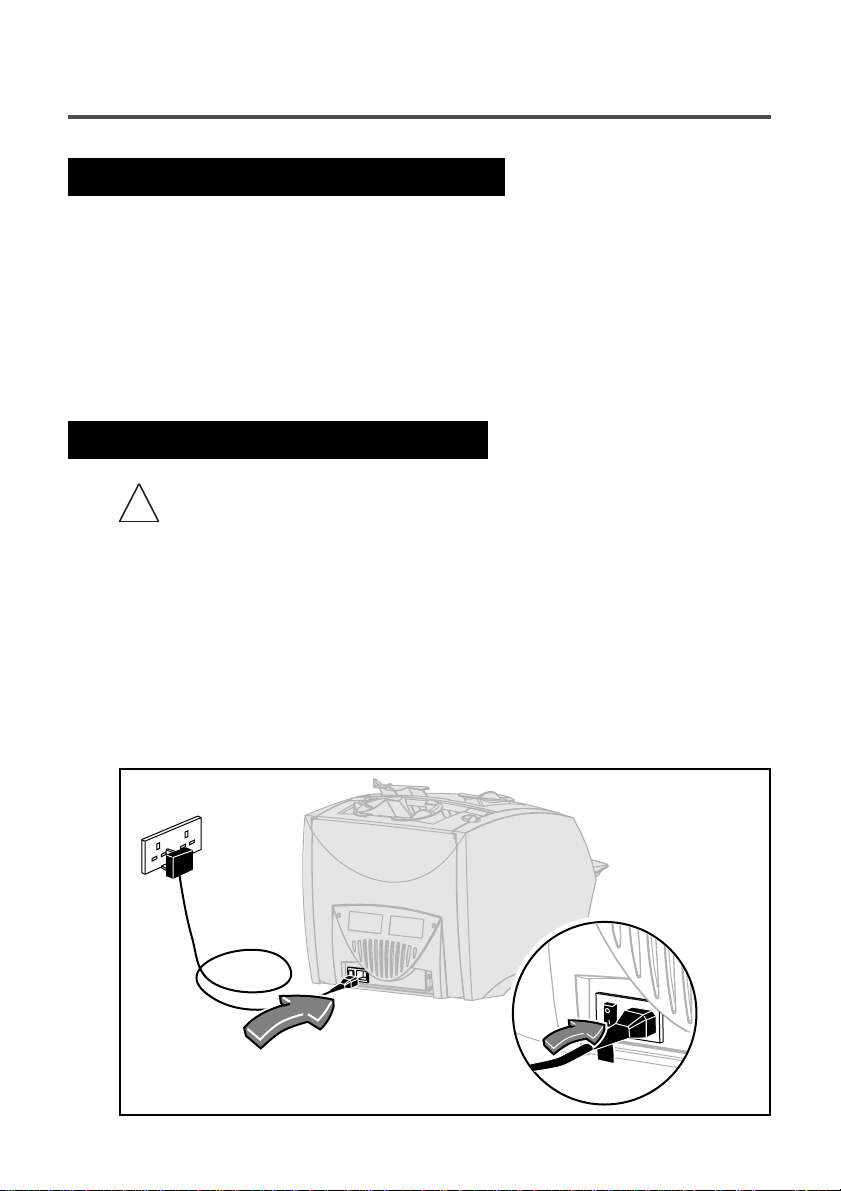

Connecting Power and Turning On … … … … … … … … … … … … … … 8

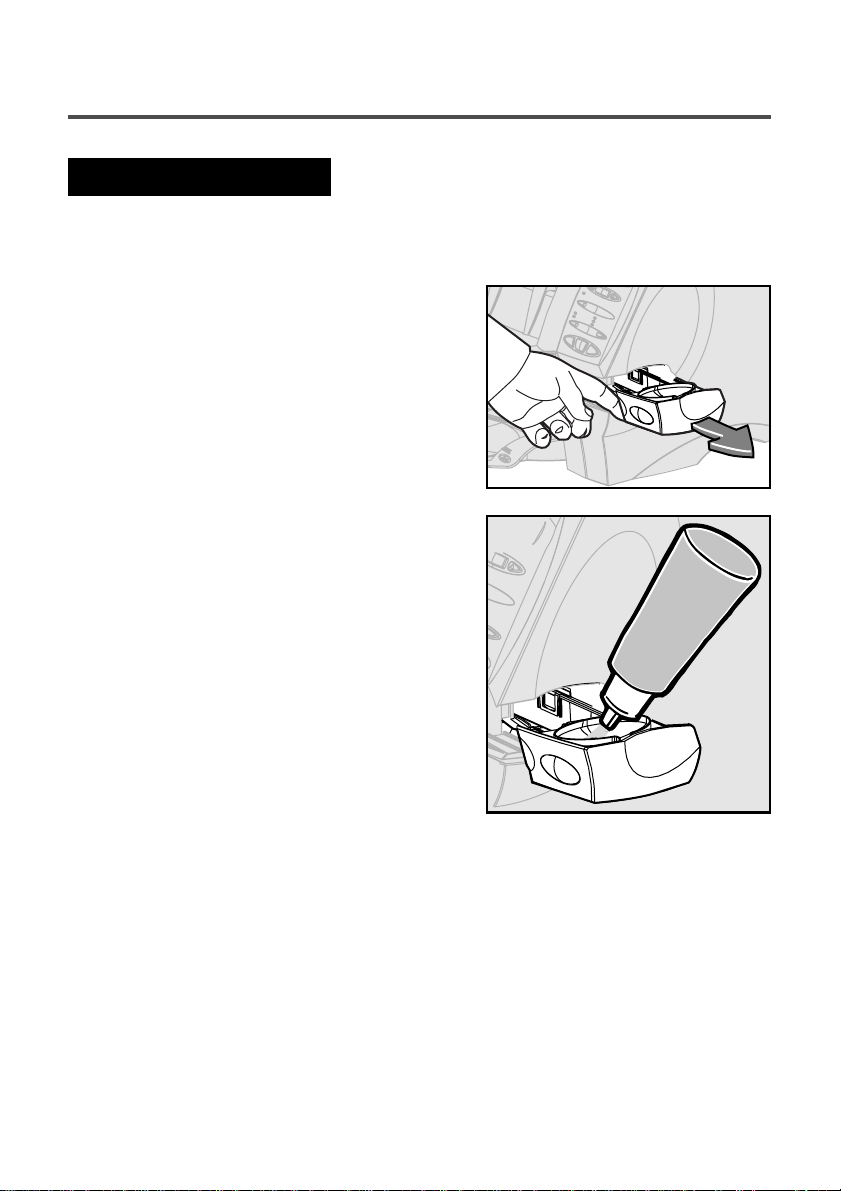

Filling the Moistener … … … … … … … … … … … … … … … … … … … 9

Loading Sheet Feeders (Feeders A1 and A2) … … … … … … … … … … … 10

Loading the Envelope Feeder (Feeder B) … … … … … … … … … … … … 11

Loading the Insert Feeder (Feeder C) … … … … … … … … … … … … … 12

3. Running Jobs

General Information/Job Listing … … … … … … … … … … … … … … … 13

Job 1 - 1 folded sheet into an envelope … … … … … … … … … … … … … 15

Job 2 - 1 folded sheet, no envelope (fold only) … … … … … … … … … … 16

Job 3 - 1 folded sheet + 1 insert into an envelope … … … … … … … … … 17

Job 4 - 1 insert into an envelope … … … … … … … … … … … … … … … 18

Job 5 - 2 folded sheets into an envelope … … … … … … … … … … … … 20

Job 6 - 2 collated folded sheets into an envelope … … … … … … … … … 21

Job 7 - 2 folded sheets, no envelope (fold only) … … … … … … … … … … 22

Job 8 - 2 collated folded sheets, no envelope (fold only) … … … … … … … 23

Job 9 - 2 folded sheets and an insert into an envelope … … … … … … … … 24

Job 10 - 2 collated folded sheets and an insert into an envelope … … … … 26

The Manual Feeder M … … … … … … … … … … … … … … … … … … 28

4. Advanced Menu Options

Reset Counter … … … … … … … … … … … … … … … … … … … … … 29

Move the address in the window … … … … … … … … … … … … … … … 29

Sheet double detect on/off … … … … … … … … … … … … … … … … … 30

Insert double detect on/off … … … … … … … … … … … … … … … … … 31

Turn safe seal on/off … … … … … … … … … … … … … … … … … … … 31

5. Reference

Error Messages … … … … … … … … … … … … … … … … … … … … … 32

General Troubleshooting … … … … … … … … … … … … … … … … … … 35

Clearing Material Stoppages … … … … … … … … … … … … … … … … 37

The Stacker … … … … … … … … … … … … … … … … … … … … … … 38

Service and Supplies … … … … … … … … … … … … … … … … … … … 38

Material Specifications … … … … … … … … … … … … … … … … … … 39

Machine Specifications … … … … … … … … … … … … … … … … … … 40

Page