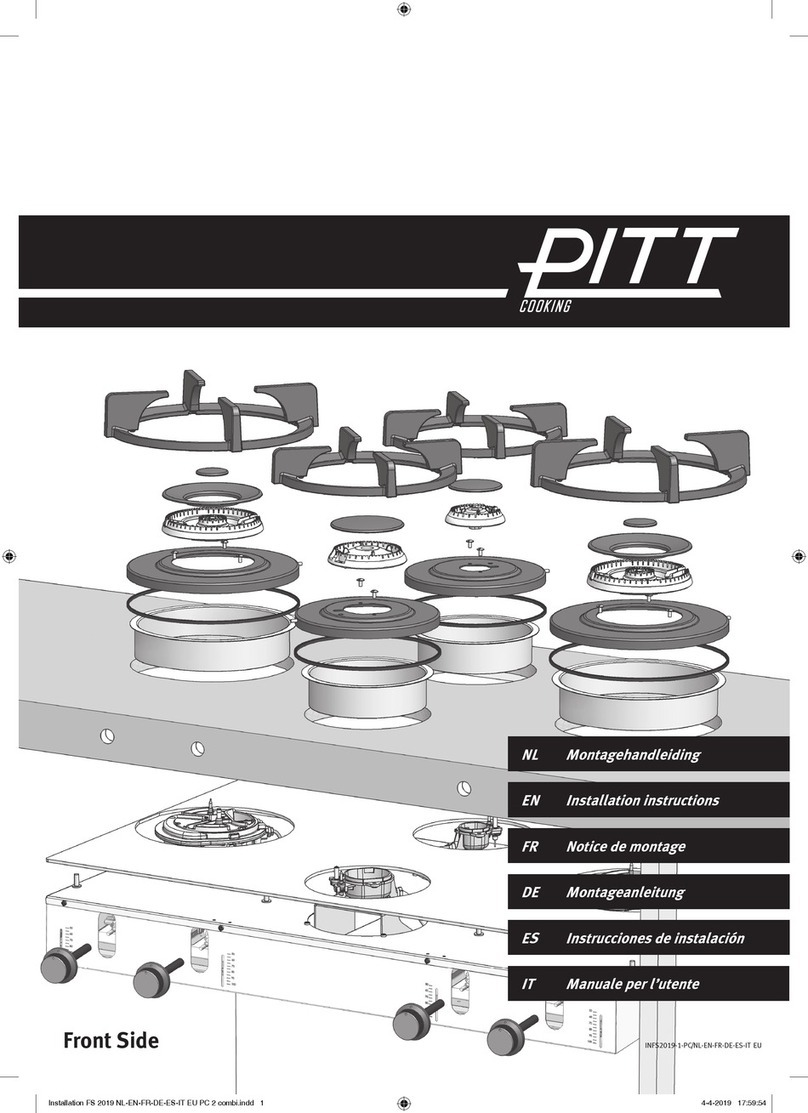

PITT Foessa User manual

Other PITT Cooktop manuals

Popular Cooktop manuals by other brands

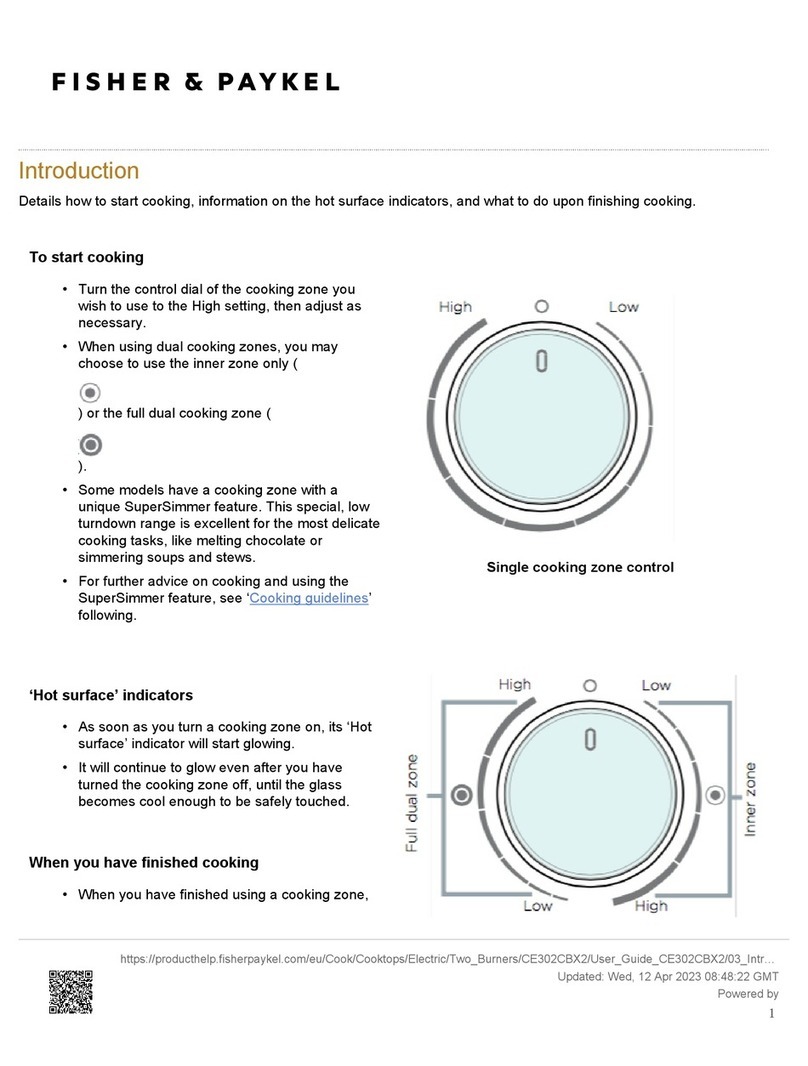

Fisher & Paykel

Fisher & Paykel CE302CBX2 manual

Whirlpool

Whirlpool GJC3634RB00 parts list

Whirlpool

Whirlpool ACH7324/BLV Use, care and installation guide

Frigidaire

Frigidaire Professional FPDF4085KF Important safety instructions

Bonnet

Bonnet OPTIMUM 700 Technical instructions

Jenn-Air

Jenn-Air JGCP430 installation instructions

Bompani

Bompani BO374AA/E User instructions

Kleenmaid

Kleenmaid cooking GCTK9011 Instructions for use and warranty details

Waldorf

Waldorf RN8603E-B Technical data sheet

Whirlpool

Whirlpool SMP658CNEIXL quick guide

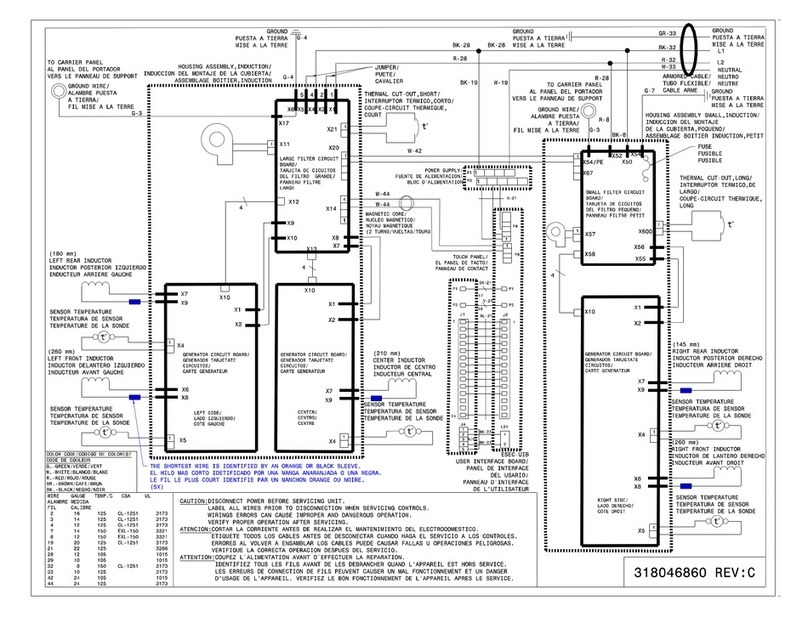

Electrolux

Electrolux E36IC80ISS - 36" Induction Cooktop Wiring diagram

Wolf

Wolf CI243C/B Use and care guide