AFP 300/400 INSTALLATION AND PROGRAMMING MANUAL PAGE 3

COPYRIGHT © 2000, NOTIFIER INERTIA PTY LTD

Programming....................................................................................................................... 20

OVERVIEW ......................................................................................................................................20

Turning the Panel on for the first Time 20

How to enter a ‘Default’ Program...............................................................................................................20

Program Mode Screen...............................................................................................................................21

Clear Program............................................................................................................................................21

Autoprogram ..............................................................................................................................................21

Duplicate (Dual) Addressing.................................................................................................................................22

Default Autoprogram Screen.................................................................................................................................23

Autoprogram Defaults...........................................................................................................................................23

Autoprogram- Device no longer needed....................................................................................................24

Installing a Device......................................................................................................................................24

Edit a Point.................................................................................................................................................24

Modifying a Point........................................................................................................................................24

Editing Multi Detector Mode.......................................................................................................................25

Programming Cooperative Multi-Detector...........................................................................................................25

Delete a Point.............................................................................................................................................26

Password ...................................................................................................................................................26

Message - Change the “SYSTEM NORMAL MESSAGE”.........................................................................26

Zone Labels ...............................................................................................................................................27

Special Zones ............................................................................................................................................27

F5-F6 (TIME CONTROL).....................................................................................................................................28

F7 (Holiday)..........................................................................................................................................................28

System Functions 29

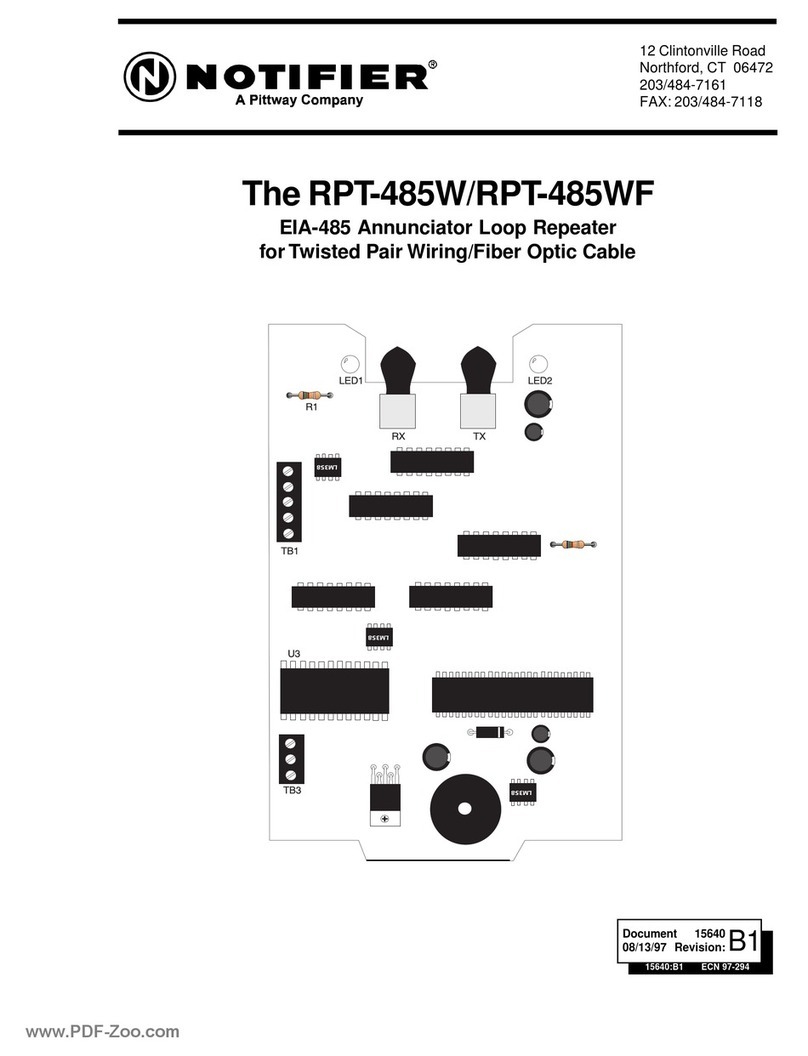

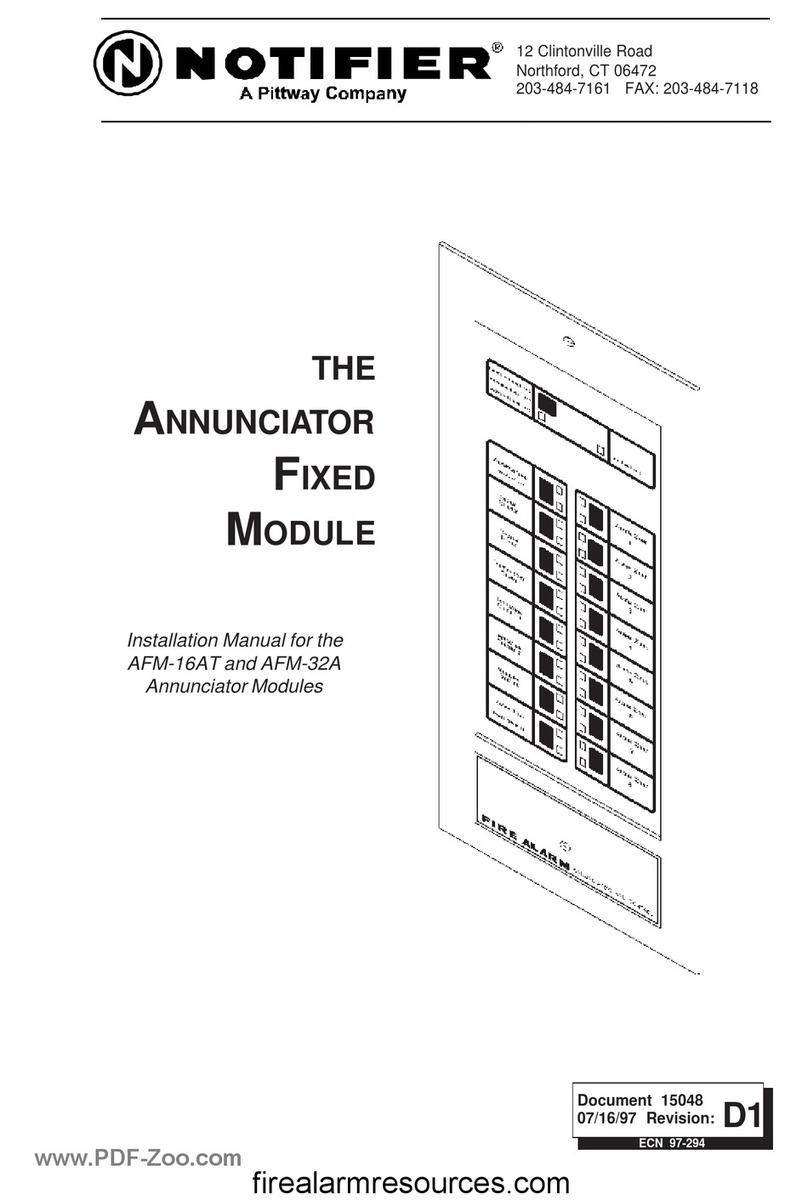

Annunciator selection 30

Annunciator Groups...................................................................................................................................30

Annunciator Group 1.............................................................................................................................................30

Annunciator Group 2.............................................................................................................................................31

Annunciator Group 3-5 .........................................................................................................................................31

Annunciator Group 6 – 8.......................................................................................................................................31

System Check Function.............................................................................................................................32

Status Change 32

Isolate a Device or Zone............................................................................................................................33

Change Sensitivity .....................................................................................................................................33

Clear Verification Counters........................................................................................................................33

Clear History..............................................................................................................................................34

Time and Date............................................................................................................................................34

Walk Test...................................................................................................................................................34

Type Codes (ID’s) 35

Monitor Module’s........................................................................................................................................35

Type Codes for Monitor Modules..........................................................................................................................35

Control Module’s........................................................................................................................................36

Type Codes for Control Modules...........................................................................................................................36

Panel’s Monitored Output Circuits .............................................................................................................36

Control-By-Event Programming 37

CBE Equation........................................................................................................................................................37

Automatically Change sensitivity ..........................................................................................................................37

Nominal Detector Sensitivity 38

Self Optimising Pre-Alarm ....................................................................................................................................38

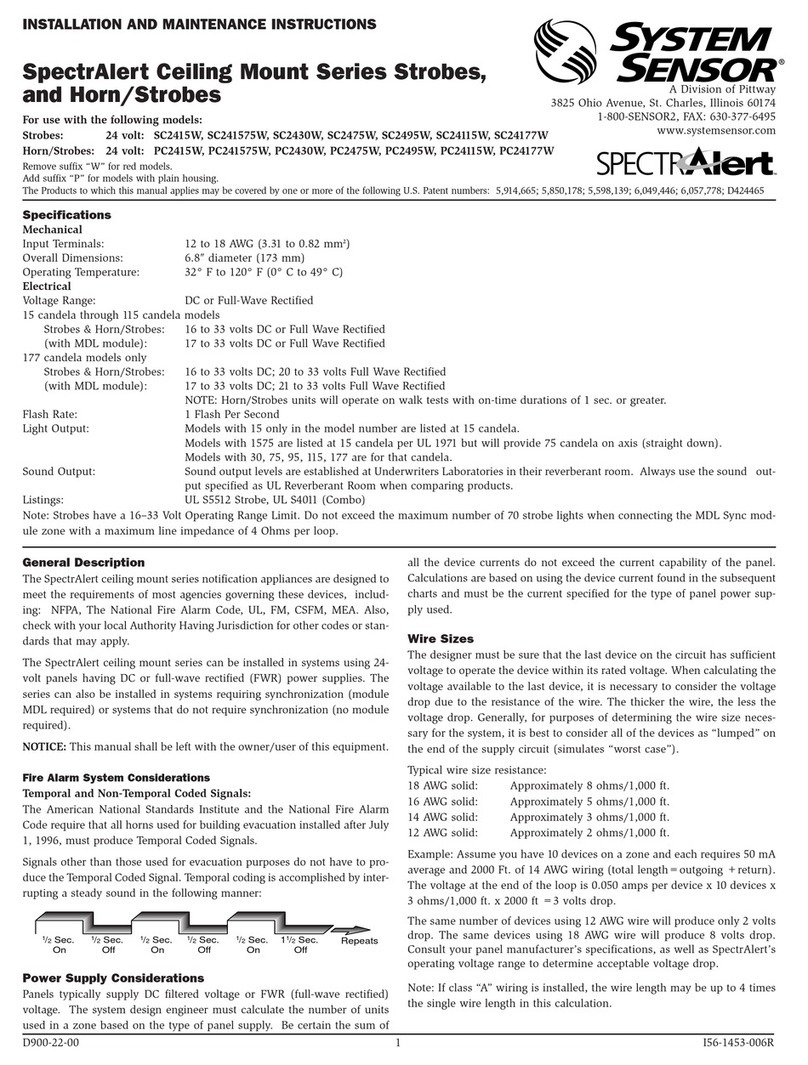

Sensitivity Levels for the AFP-400: (Graph)...............................................................................................39

Sensitivity Levels- Autoprogram Default Tables:..................................................................................................40

Technical Manuals Online! - http://www.tech-man.com