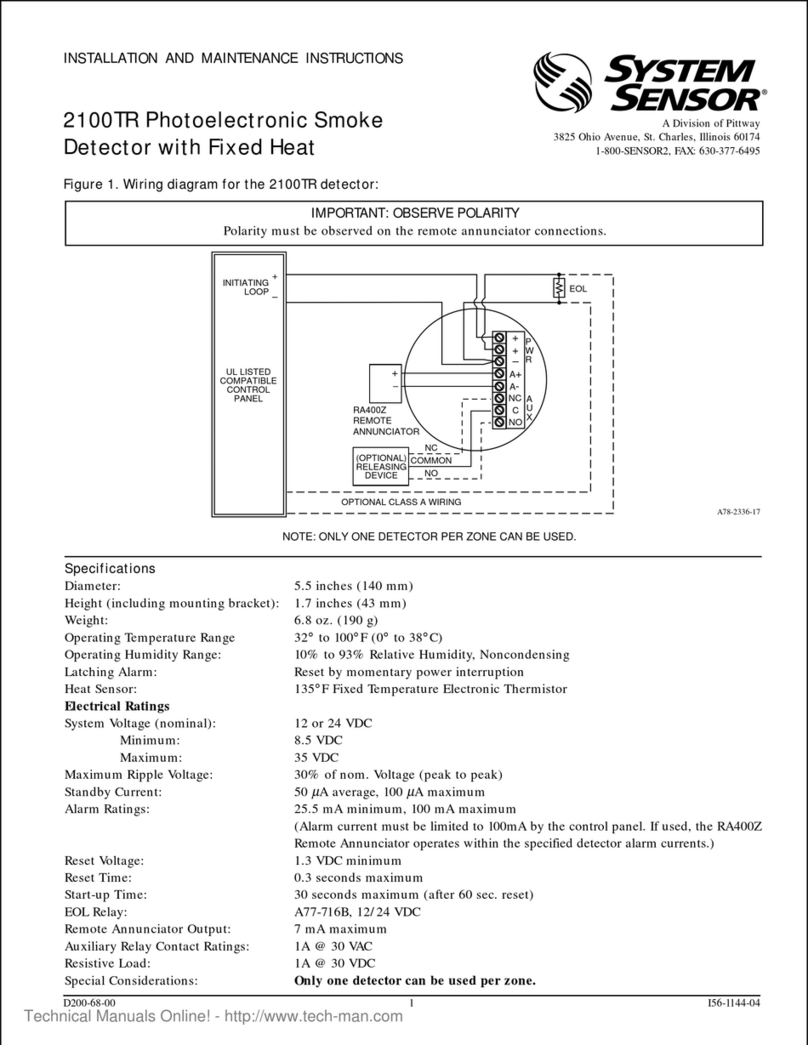

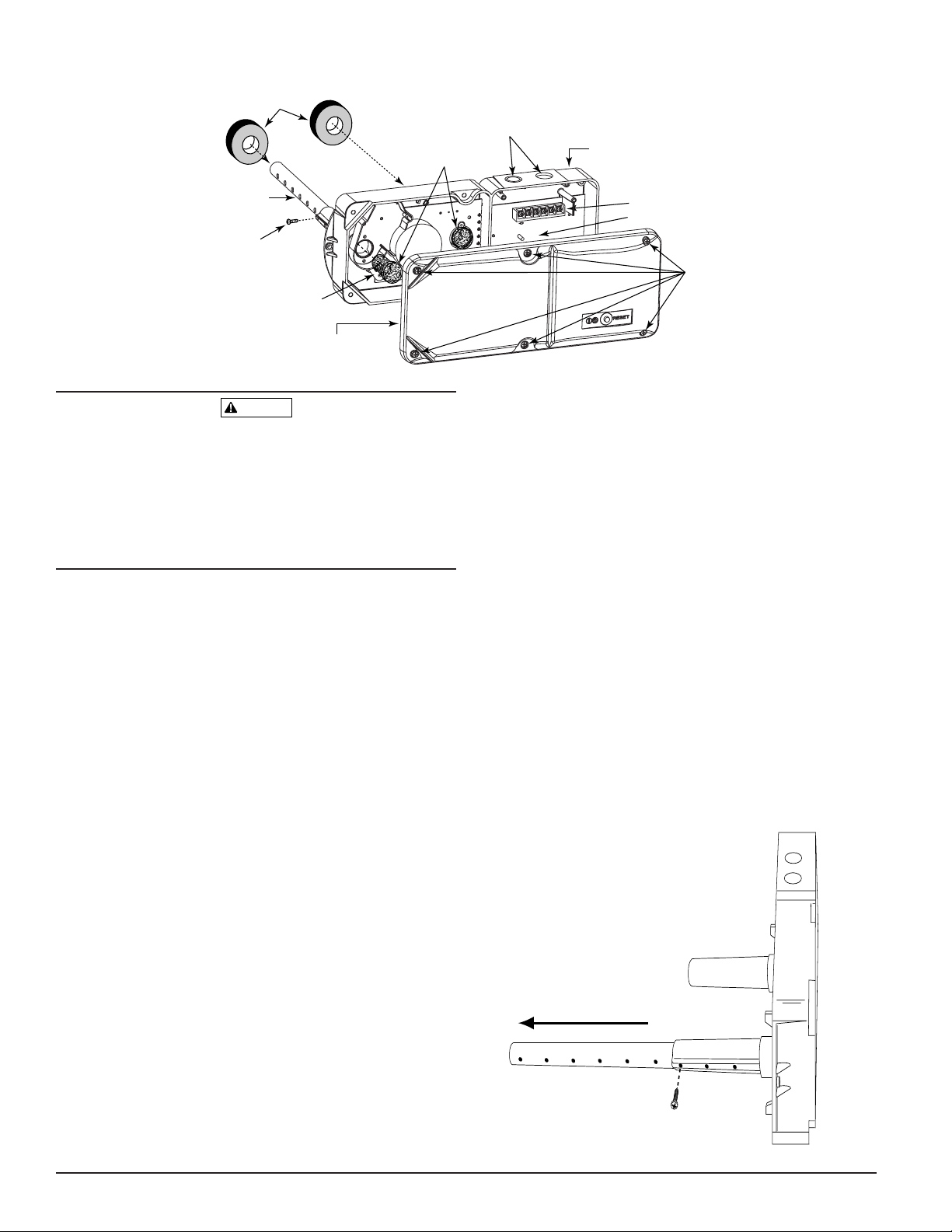

For signal wiring, (the wiring between interconnected

detectors or from detectors to auxiliary devices), it is usu-

ally recommended that single conductor wire be no small-

er than 18 gauge. The duct smoke detector terminals

accommodate wire sizes up to 12 gauge. The last foot of

conduit should be flexible conduit (available in electrical

supply houses), which facilitates easier installation and

puts less strain on the conduit holes in the housing. Solid

conduit connections may be used if desired.

Smoke detectors and alarm system control panels have

specifications for allowable loop resistance. Consult the

control panel manufacturer’s specifications for the total

loop resistance allowed for the particular model control

panel being used before wiring the detector loop.

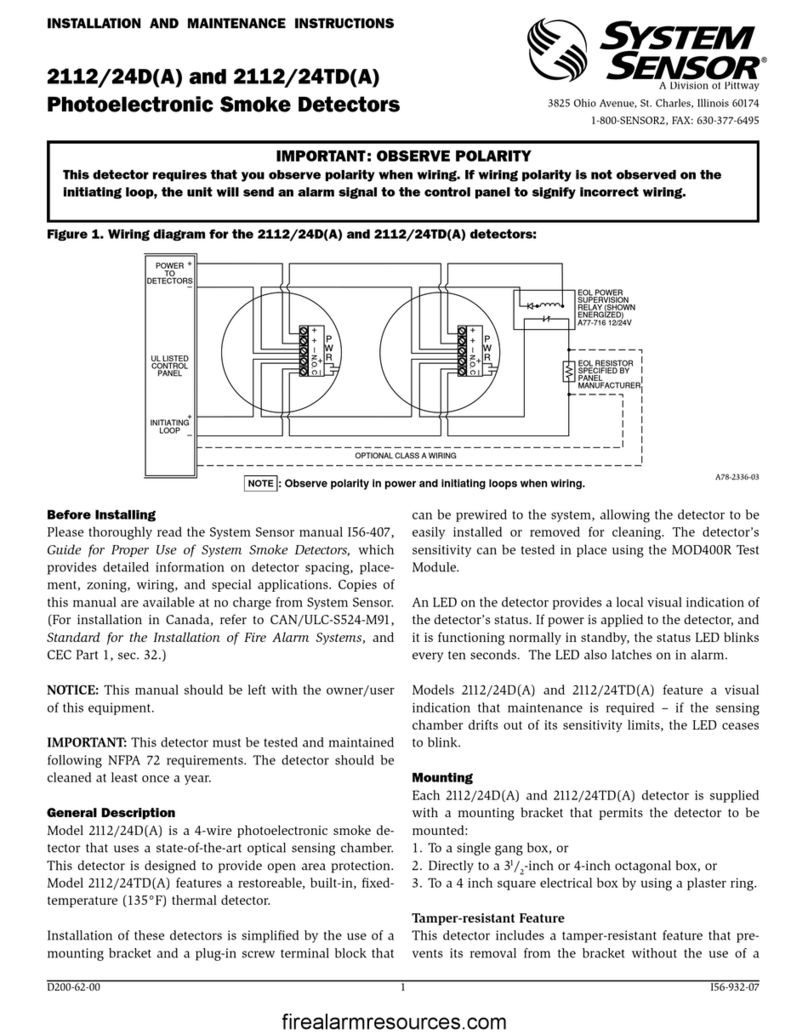

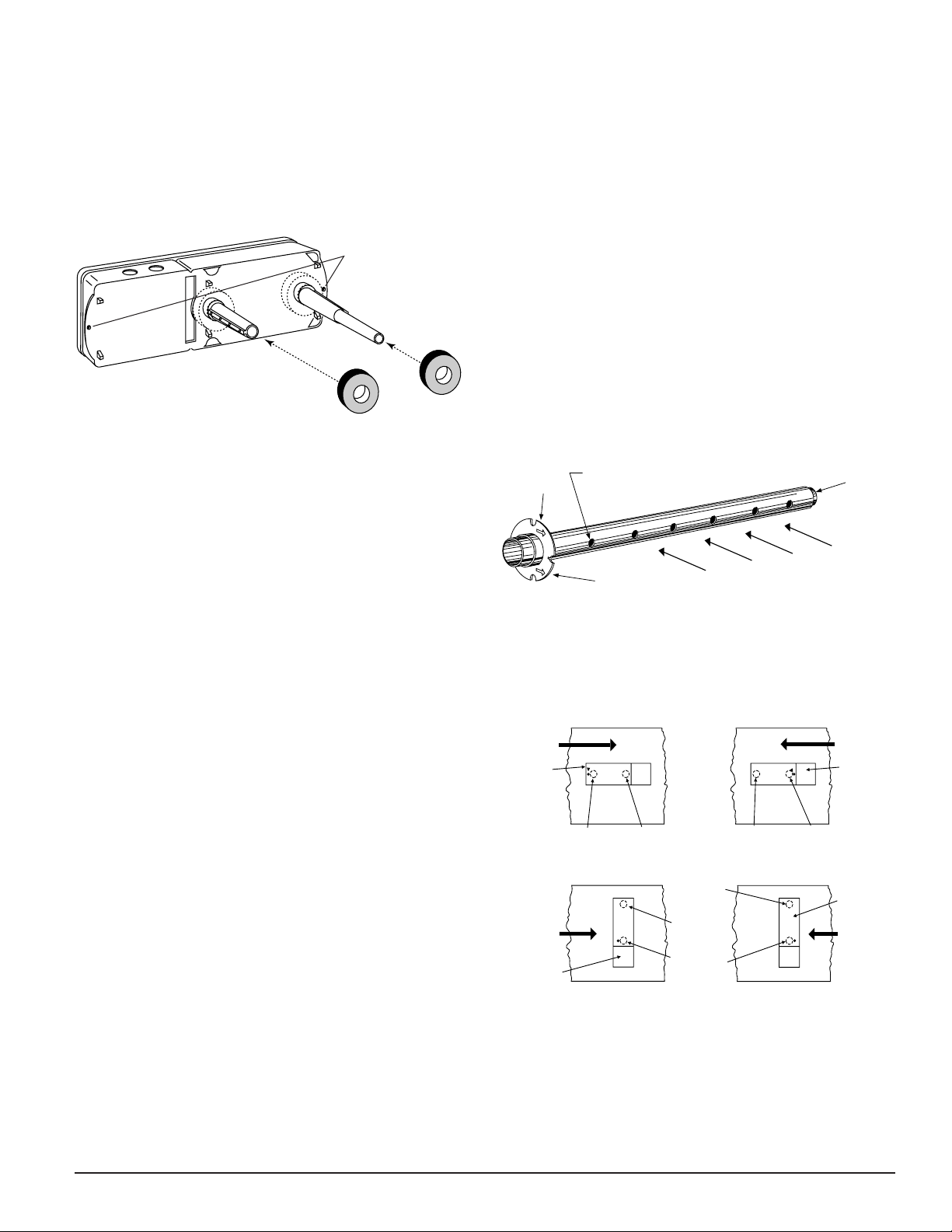

Wiring Instructions

The DH100LP detectors are designed for easy wiring. The

housing provides a terminal strip with clamping plates.

Wiring connections are made by stripping about 3/8-inch

of insulation from the end of the wire, sliding the bare end

under the plate, and tightening the clamping plate screw.

The DH100LP duct smoke detector is designed to operate

with 12 or 24 VDC UL listed 2-wire compatible control pan-

els. Alarm current must be limited by the control panel to

100mA or less. An example of a UL listed compatible con-

trol panel is the Fire-Lite model Sensiscan 1000 using zone

card ANC-2 and compatibility identification “A”. Install per

installation instruction S1000/801. A maximum of 20 detec-

tors may be installed per zone.

[5.7] Perform Detector Check

1. Perform STANDBY AND TROUBLE TEST per Section

[6.2.1].

2. Perform MAGNET TEST per Section [6.2.2.1]. The

RTS451 test of Section [6.2.2.2] may substitute for this

requirement.

3. Perform AIR FLOW TEST per Section [6.1.1].

4. Perform SMOKE RESPONSE TEST per Section [6.1.2].

5. Perform SENSITIVITY TEST per Section [6.2.3].

[5.8] Install The Cover

Install the cover using the six screws that are captured in

the housing cover. Be certain filters are installed as speci-

fied in Section [5.5]. Make sure that the cover fits into the

base groove and that all gaskets are in their proper posi-

tions. Tighten the six screws.

[6] Duct Smoke Detector Maintenance And Test

Procedures

Test and maintain duct smoke detectors as recommended

in NFPA 72. The tests contained in this manual were

devised to assist maintenance personnel in verification of

proper detector operation.

Before conducting these tests, notify the proper authorities

that the smoke detection system will be temporarily out of

service. Disable the zone or system under test to prevent

unwanted alarms.

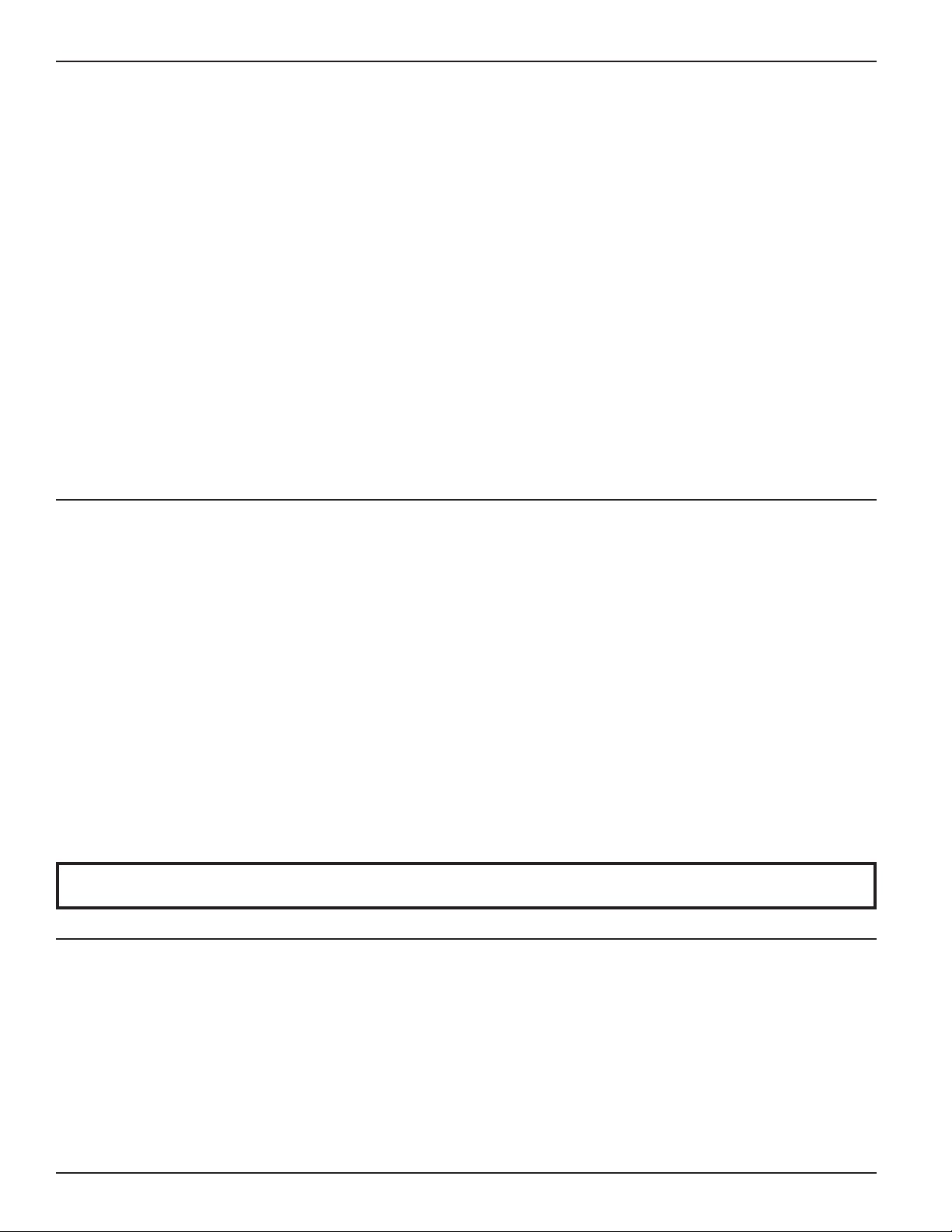

[6.1] Smoke Entry Tests

[6.1.1] Air Flow

The DH100LP is designed to operate over an extended air

speed range of 100 to 4000 FPM. To verify sufficient sampling

of ducted air, turn the air handler on and use a manometer to

measure the differential pressure between the two sampling

tubes. The differential pressure should measure at least

0.0015 inches of water and no more than 1.2 inches of water.

Because most commercially available manometers cannot

accurately measure very low pressure differentials, applica-

tions with less than 500 FPM of duct air speed may require

one of the following: 1) the use of a current-sourcing pressure

transmitter (Dwyer model numbers 607-1 or 607-01) see field

bulletin Z75-79-00 or; 2) the use of aerosol smoke per sec-

tion 6.1.2.

[6.1.2] Air Flow Test using Aerosol Smoke

Drill a 1⁄4″hole 3 feet upstream from the duct smoke detec-

tor. With the air handler on, measure the air velocity with

an anemometer. Air speed must be at least 100 FPM. If the

air speed is greater than 500 FPM, use a conventional

manometer to measure differential pressure between the

sampling tubes. Spray aerosol smoke* into the duct through

the 1⁄4″hole for five seconds. Wait two minutes for the duct

smoke detector to alarm. If the duct smoke detector alarms,

air is flowing through the detector. Remove the duct smoke

detector cover and blow out the residual aerosol smoke from

the chamber and reset the duct smoke detector. Use duct

tape to seal the aerosol smoke entry hole.

*Aerosol smoke can be purchased from Home Safeguard Industries,

Malibu, CA. Phone: 310/457-5813.

To determine if smoke is capable of entering the sensing

chamber, visually identify any obstructions. Plug the

exhaust and inlet tube holes to prevent ducted air from car-

rying smoke away from the detector head, then blow smoke

such as cigarette, cotton wick, or punk directly at the head

to cause an alarm. REMEMBER TO REMOVE THE PLUGS

AFTER THIS TEST, OR THE DETECTOR WILL NOT FUNC-

TION PROPERLY.

[6.1.3] Filter Replacement

The filters do not substantially affect smoke performance

even when up to 90% of the filter is clogged. Quarterly

visual inspection usually suffices to determine whether the

filters should be replaced because only a high percentage of

contamination affects performance. If further testing is

required, compare differential pressure readings with and

without the filters installed. If the difference exceeds 10%

replace the filters. In no case should the pressure differen-

tial fall below 0.0015 inches of water.

D200-15-00 5 I56-0083-00