ATLAS 2 of 44 User’s Manual

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................................................2

IMPORTANT SAFETY INSTRUCTIONS....................................................................................................3

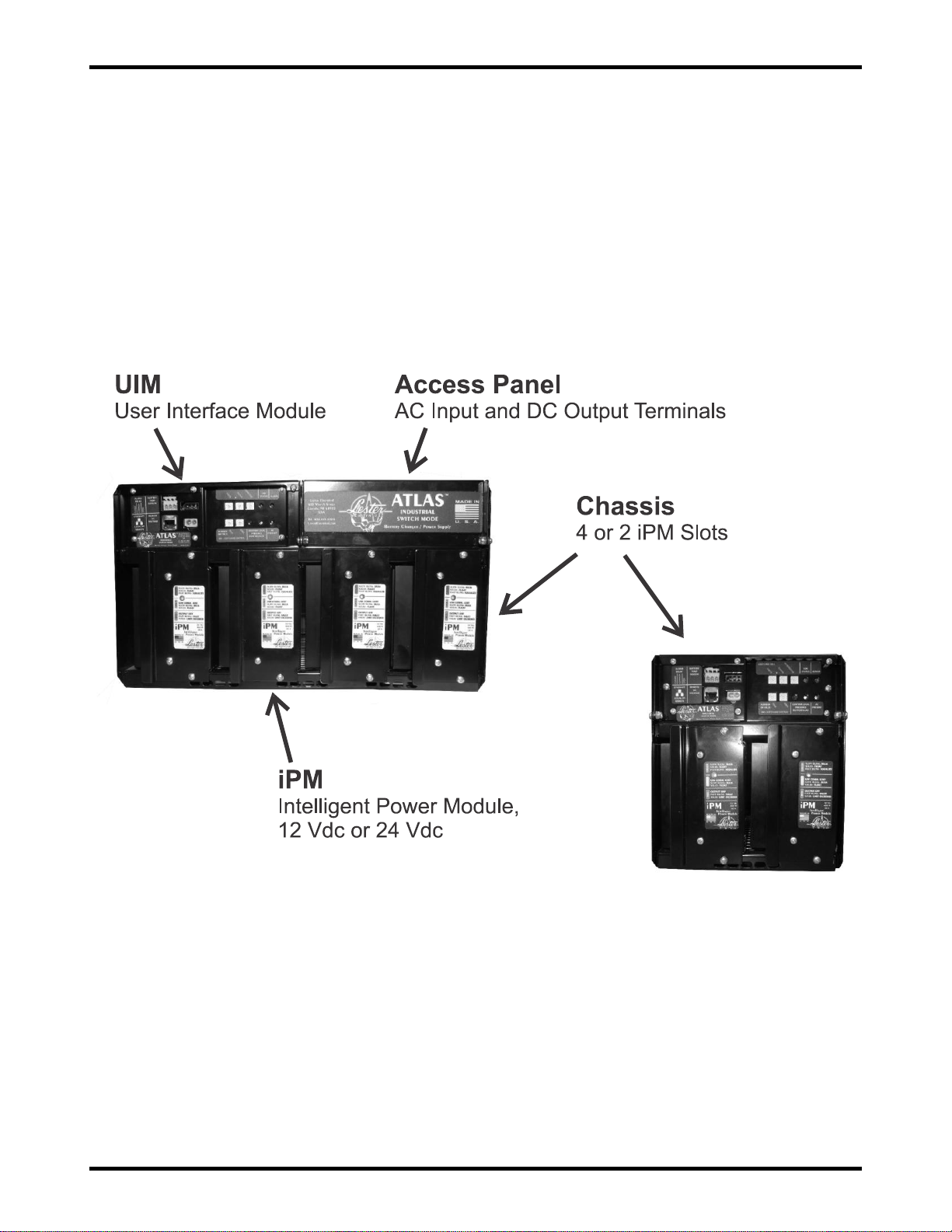

1. INTRODUCTION.................................................................................................................................5

2. THEORY OFOPERATION................................................................................................................6

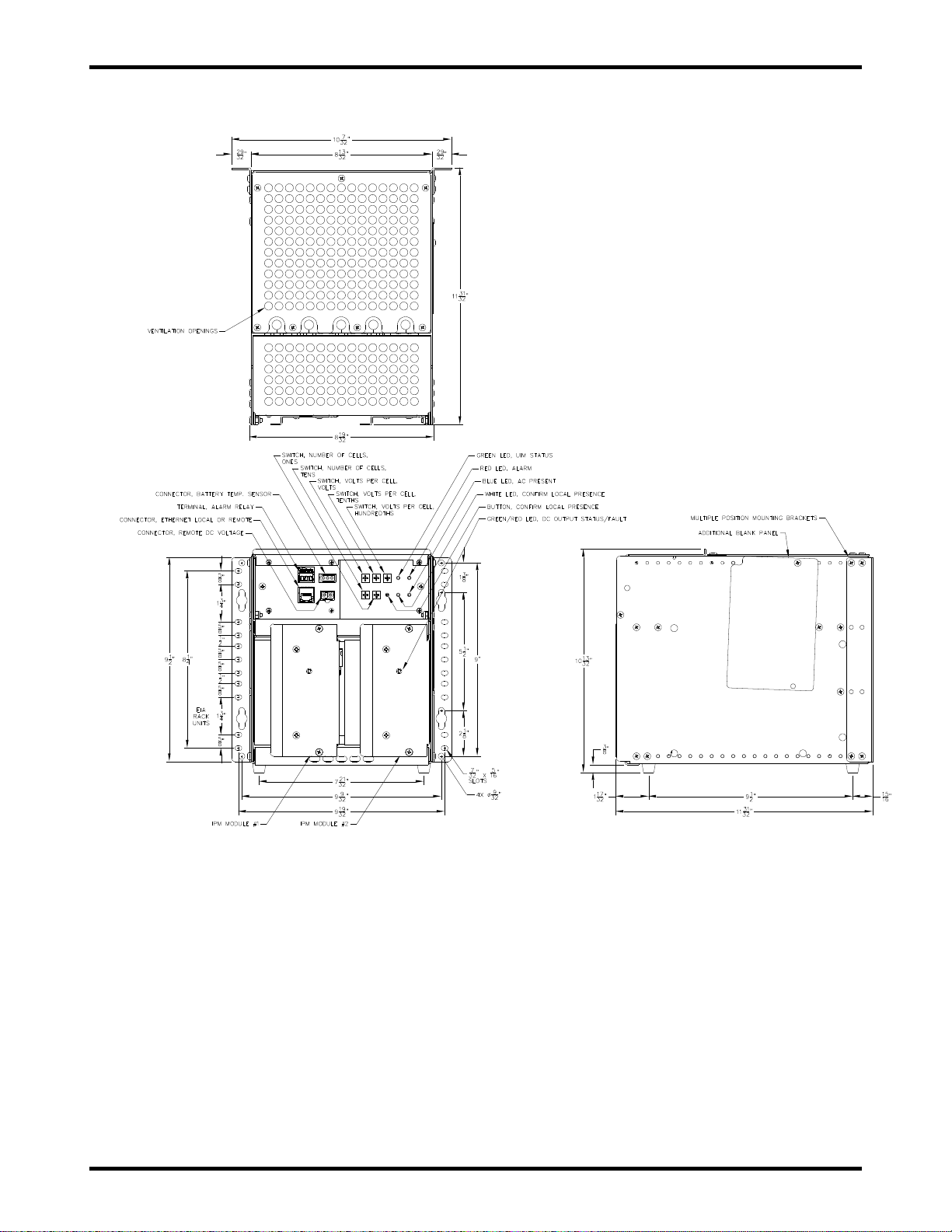

3. RECEIVING AND INSTALLING THE CHARGER.............................................................................6

4. AC INPUT ...........................................................................................................................................9

5. DC OUTPUT.......................................................................................................................................9

6. BATTERY TEMPERATURE SENSOR............................................................................................10

7. USER INTERFACE MODULE (UIM)...............................................................................................11

7.1. User Interface Module (UIM)...................................................................................................11

7.2. Digital Meter...........................................................................................................................12

8. CHARGER OPERATION.................................................................................................................13

9. LED INDICATORS...........................................................................................................................14

9.1. UIM LEDs...............................................................................................................................14

9.2. iPM Bi-Color LED ...................................................................................................................15

10. ETHERNET COMMUNICATION......................................................................................................15

10.1. Direct Local Communication .................................................................................................15

10.2. Networked Remote or Local Communication ........................................................................16

10.3. Manual (Static) Mode .............................................................................................................16

10.4. Changing the Ethernet Port Settings .....................................................................................17

10.5. Automatic (DHCP) Mode ........................................................................................................18

10.6. Restoring the Factory-Default Ethernet Port Settings............................................................19

11. WEB SERVER..................................................................................................................................19

11.1. Dashboard .............................................................................................................................19

11.2. Configuration >> System Settings.........................................................................................22

11.3. Configuration >> Charge Settings .........................................................................................22

11.4. Configuration >> Alarm Settings ...........................................................................................25

11.5. Configuration >> Date and Time Settings ..............................................................................27

11.6. Configuration >> Ethernet Settings >> Ethernet Port.............................................................27

11.7. Configuration >> Ethernet Settings >> SNMP ........................................................................28

11.8. Configuration >> User Accounts ...........................................................................................28

11.9. Configuration >> Upgrades....................................................................................................30

11.10. History ...................................................................................................................................31

11.11. Logout ...................................................................................................................................34

12. MAINTENANCE................................................................................................................................34

13. TROUBLESHOOTING AND SERVICING.......................................................................................34

13.1. ATLAS Charger Troubleshooting Chart.................................................................................35

13.2. UIM Replacement Information................................................................................................38

13.3. Service Parts List...................................................................................................................39

14. CHARGER WIRE DIAGRAMS ........................................................................................................40

15. SPECIFICATIONS............................................................................................................................42