Cap Lamp - SMARTLIGHT 05 Mk3

Operating & Maintenance Manual

CAP LAMP

OPERATION

Revision A

Operating&Maintenance Manual SM-

05 Mk3 Page 7 of 12

4.1.3 Monitoring Battery Capacity

After the lamp is switched on for the first time so is the microcontroller. At that time the

microprocessor does not have any information about the state of the charge of the battery. The

process of battery’s initial discharge is based on the voltage measurement.

After the battery is discharged and subsequently fully charged all control of the charge level is

maintained by the microcontroller which measures the flow of the electric charge from and to the

battery. In parallel with the charge flow measurement the microcontroller monitors the time the

diodes are switched on. During working cycle (lamp usage) from fully charged, the minimum time

the MLED must be able to emit light at 100% intensity is 10 hours. After that time the base factor

determining the functioning of the lamp is the amount of consumed charge. Once the total consumed

charge reaches 9Ah the normal operation of the lamp is disabled. During this period ALED can be

switched on for a period of 3 seconds at the time. During the lamp usage, in parallel with the used

charge measurement the battery voltage is measured. Once the voltage drops below 3V then

irrespective of the time the MLED is switched on or the amount of consumed charge the whole

operation of the lamp is EMERGENCY DISABLED.

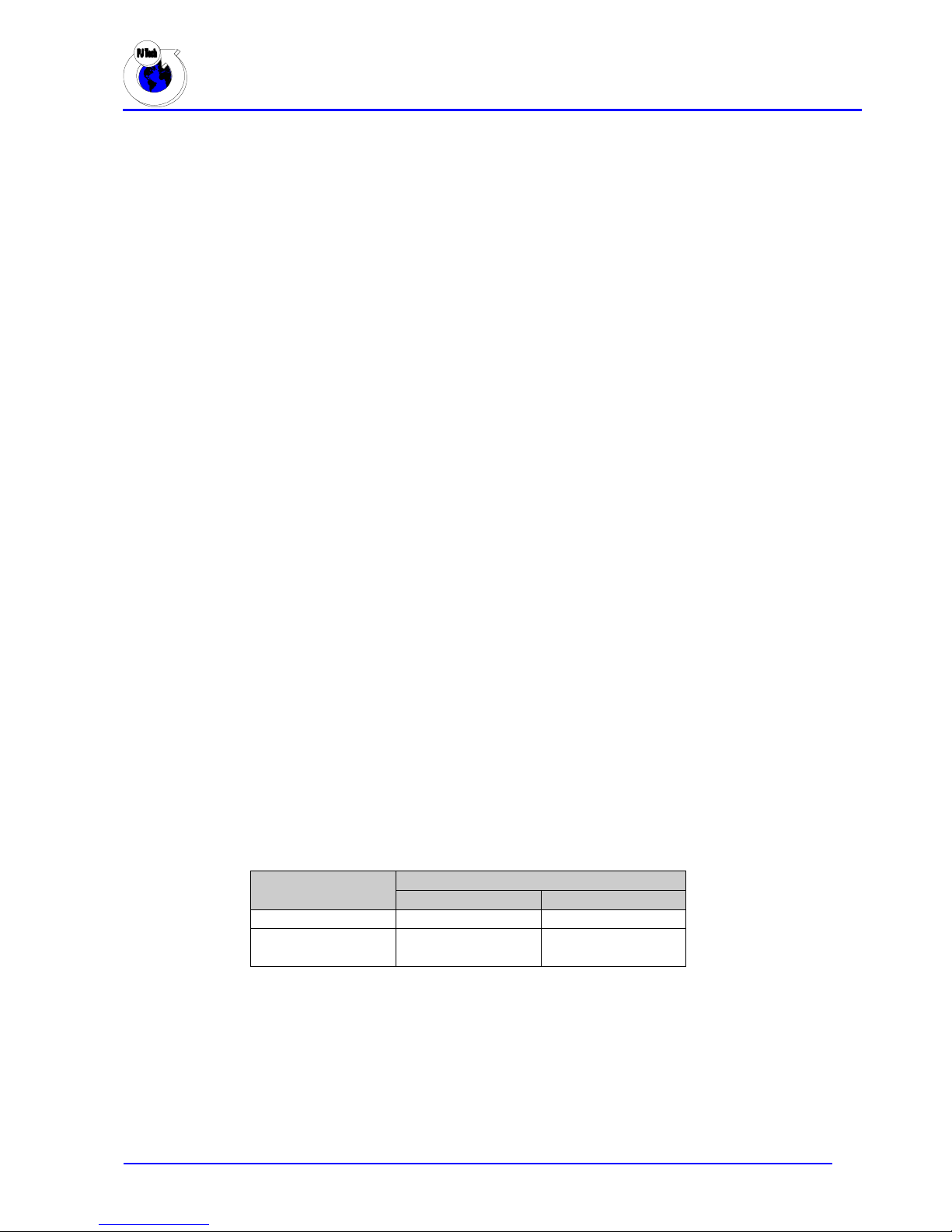

During lamp usage the microcontroller indicates the following levels of discharge:

•80% discharge of the capacity dedicated to the lamp - MLED flashes 6 times

•99% discharge of the capacity dedicated to the lamp – MLED flashes 3 times

Actual level of battery’s remaining capacity is constantly indicated by the ELED flashing as follows:

•81-100% capacity remaining – ELED flashes 5 times

•61 -80% capacity remaining – ELED flashes 4 times

•41-60% capacity remaining – ELED flashes 3 times

•21-40% capacity remaining – ELED flashes 2 times

•0-20% capacity remaining – ELED flashes 1 time

The ELED flashes in the following pattern: 200ms – flash, 300ms pause, 2.5s pause between the

cycles.

4.2 Battery Charging

4.2.1 Battery Chargers

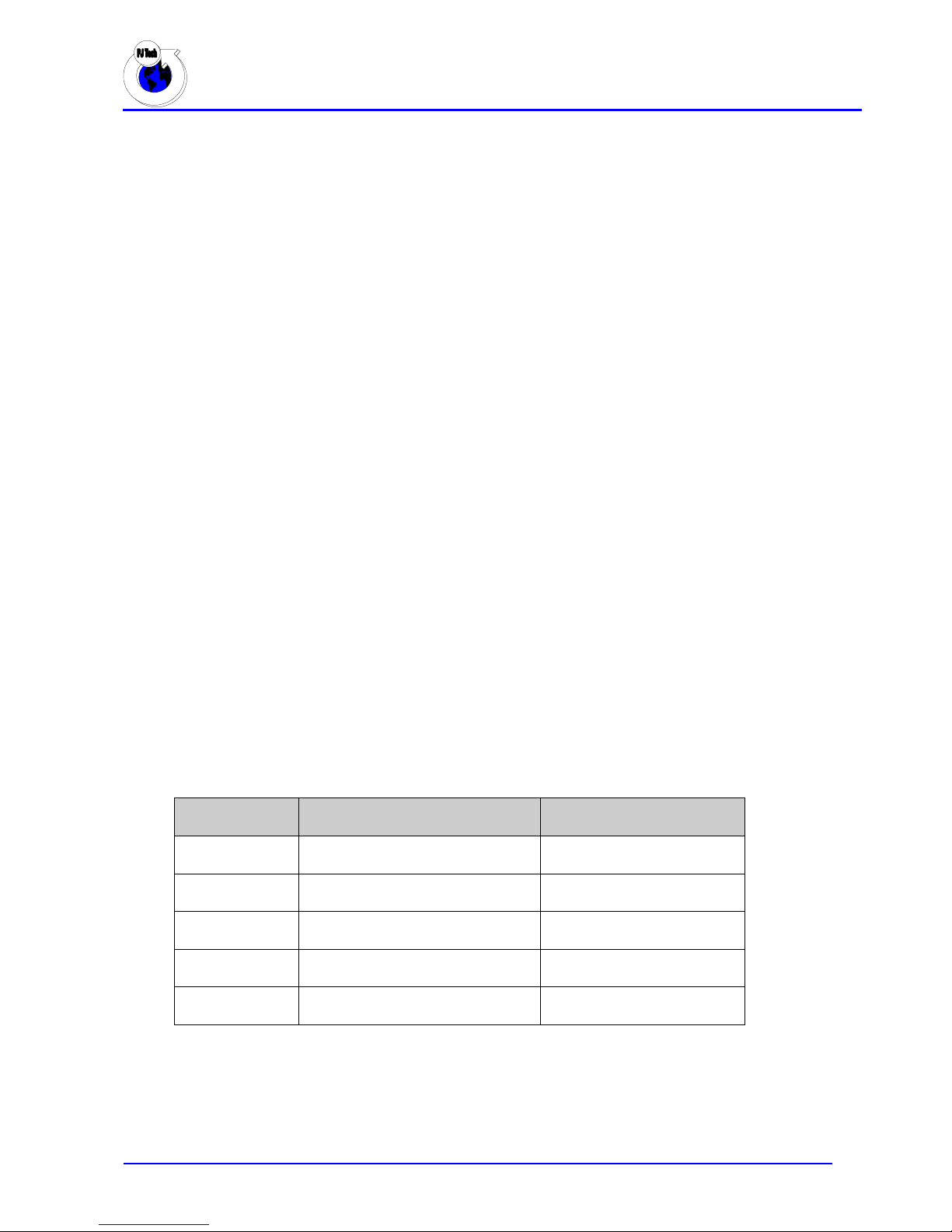

The SMARTLIGHT-05/M1 cap lamps to be charged only in the following charging devices:

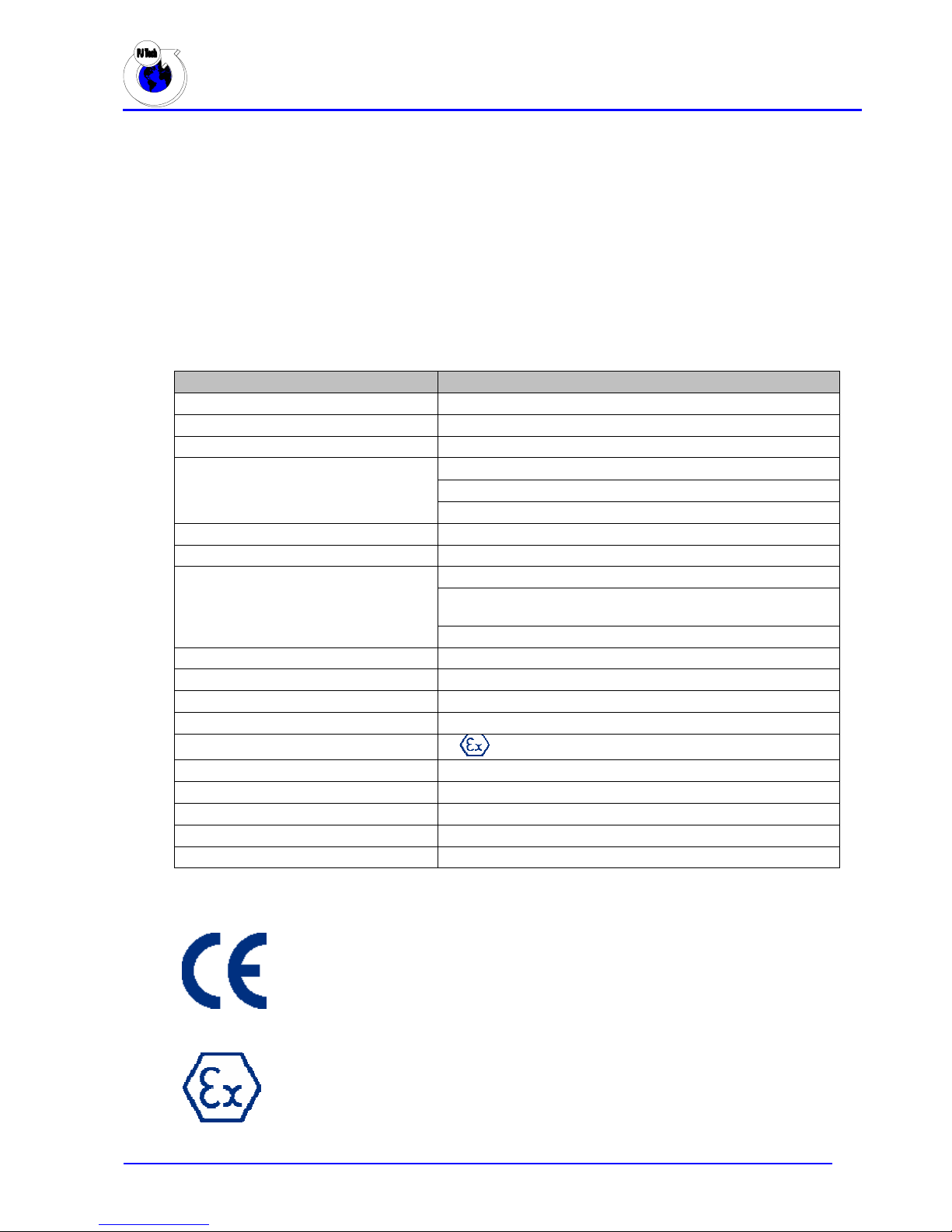

Charger Lamp

Capacity Charger

Type Part Number

1

Charger module only

(any charger type) PCL-SM05-CHRG/MOD

1 Single (desktop)

PCL-SM05-CHRG/1

5 Stand alone

(desktop or bench) PCL-SM05-CHRG/5

17 Row

(part of PCL-SM05-CHRG/102) PCL-SM05-CHRG/17

102 Stand Alone

PCL-SM05-CHRG/102

IMPORTANT NOTE!

All lamps are delivered with discharged and conditioned batteries

To enable initial battery charge the electronic board with microcontroller must be connected to

the battery by means of a connector under the battery casing cover (Figure 1-3)