Table of Contents

Safety Information..................................................................................................................2

Device description..................................................................................................................4

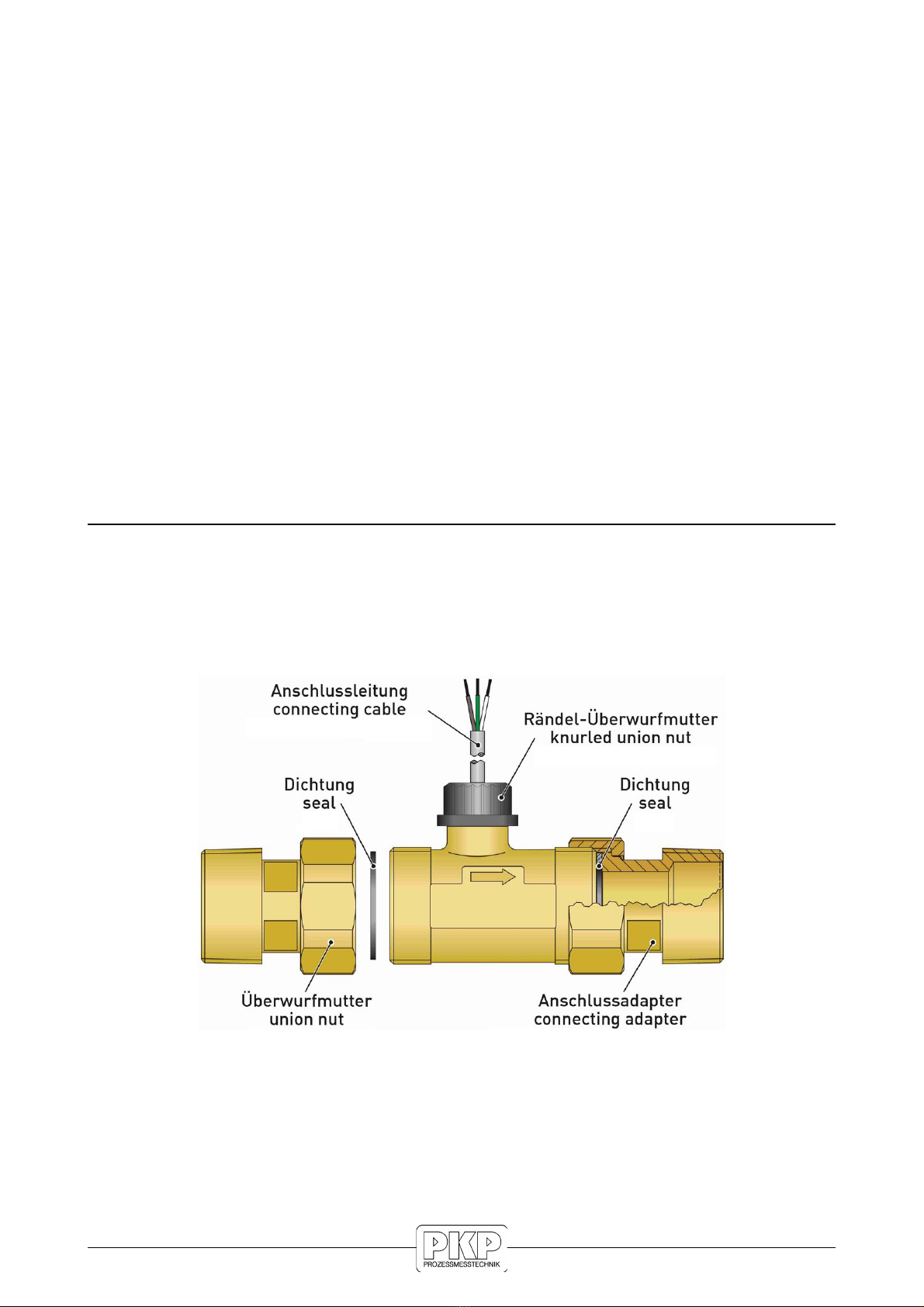

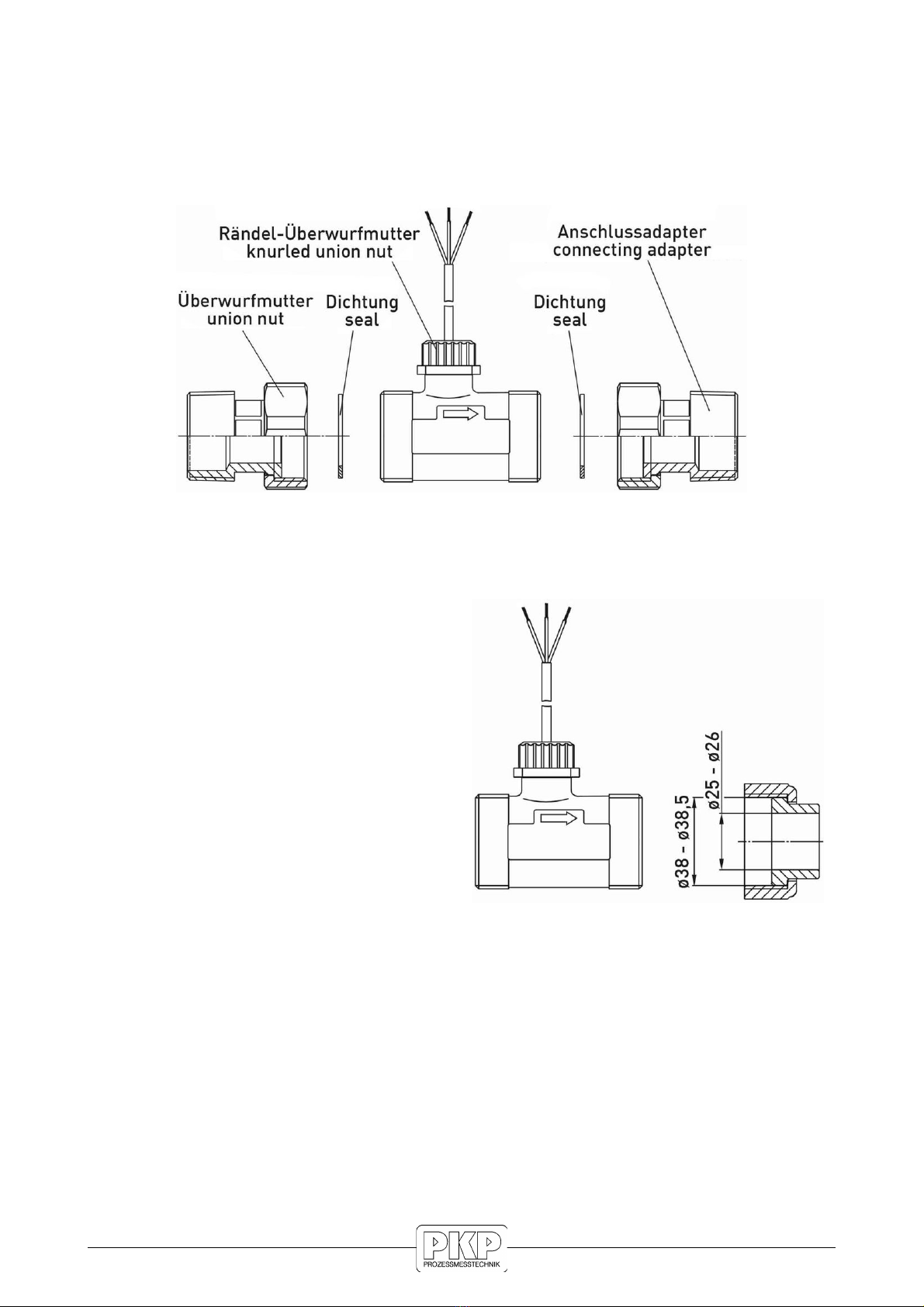

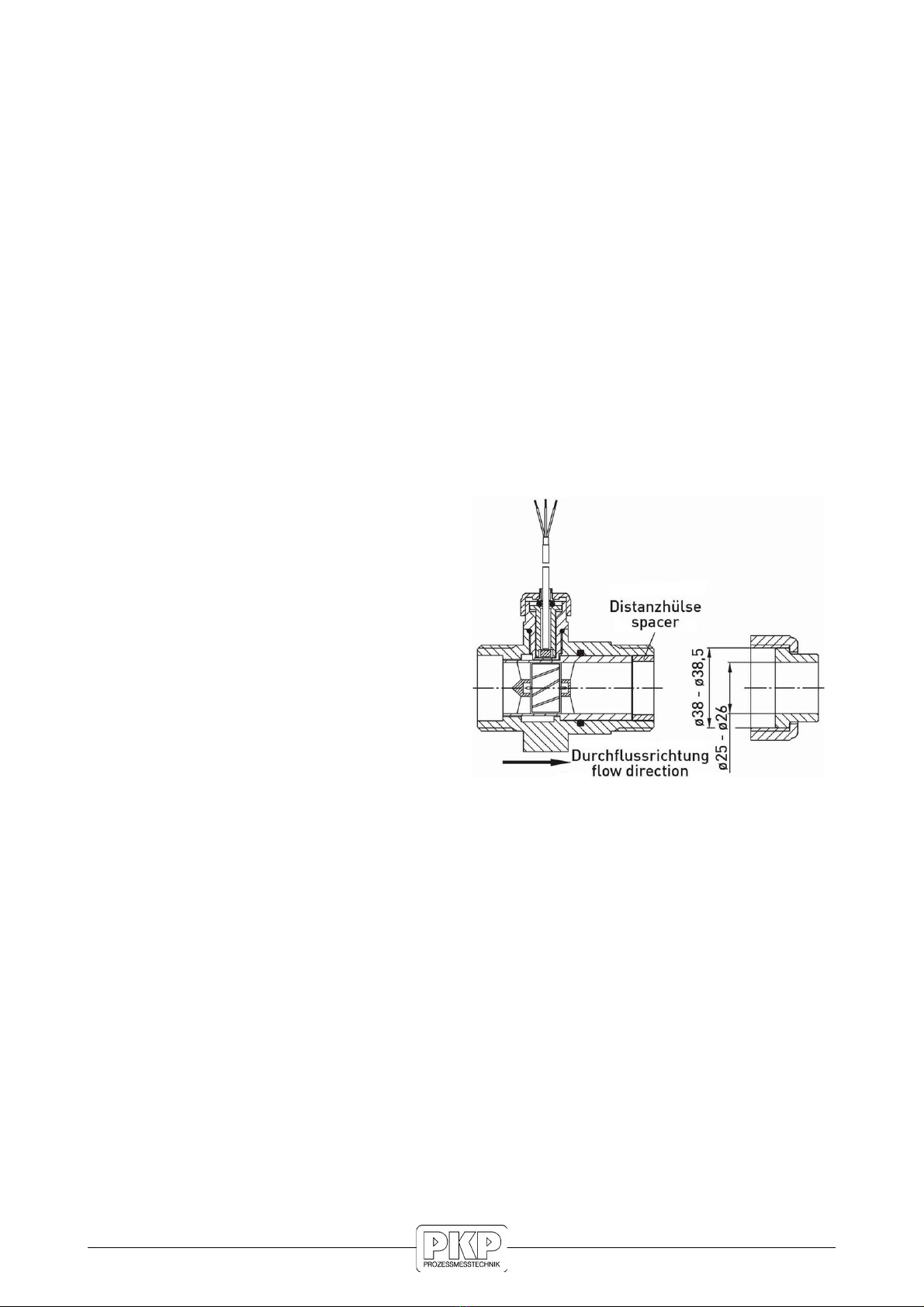

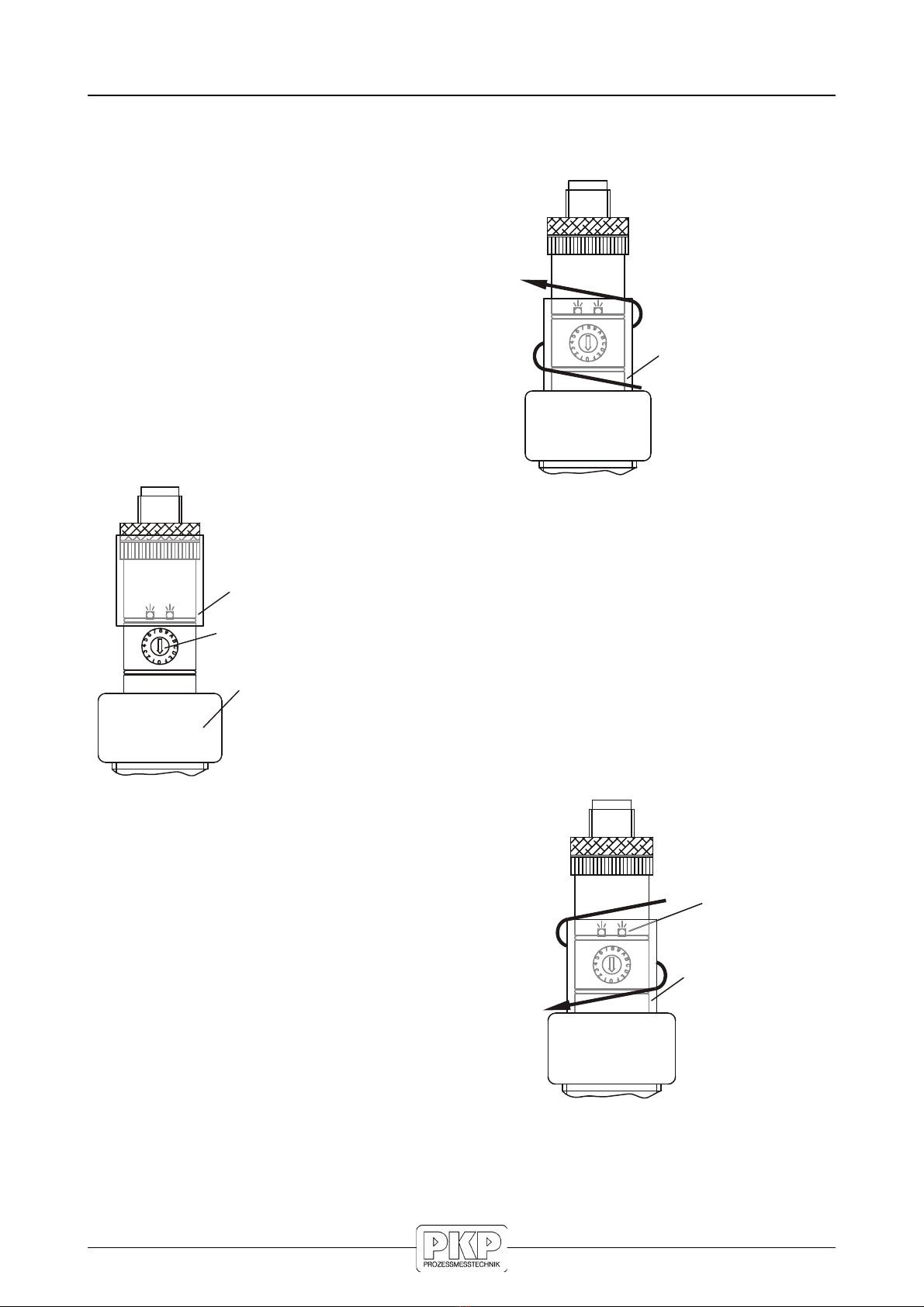

Installation..............................................................................................................................5

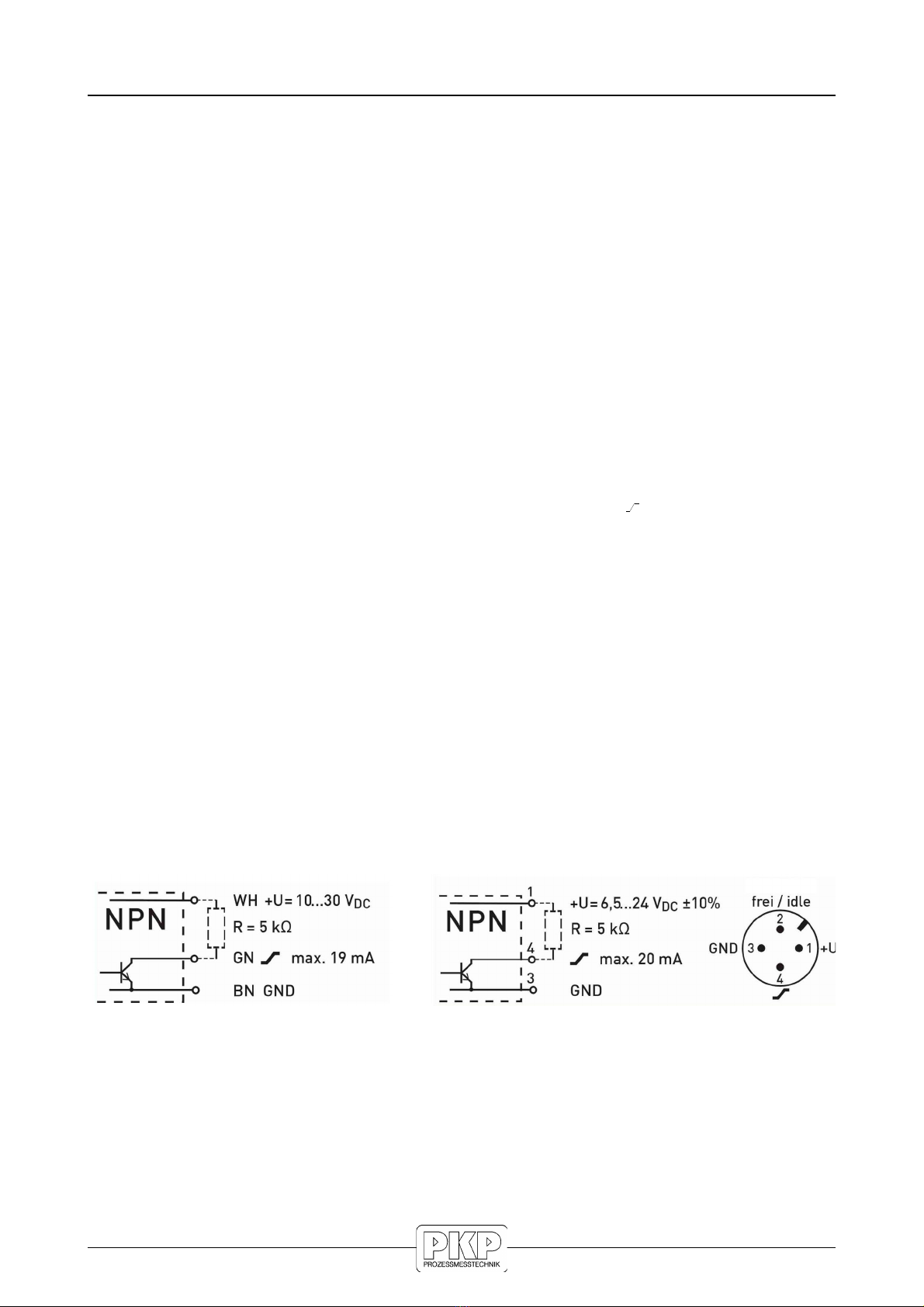

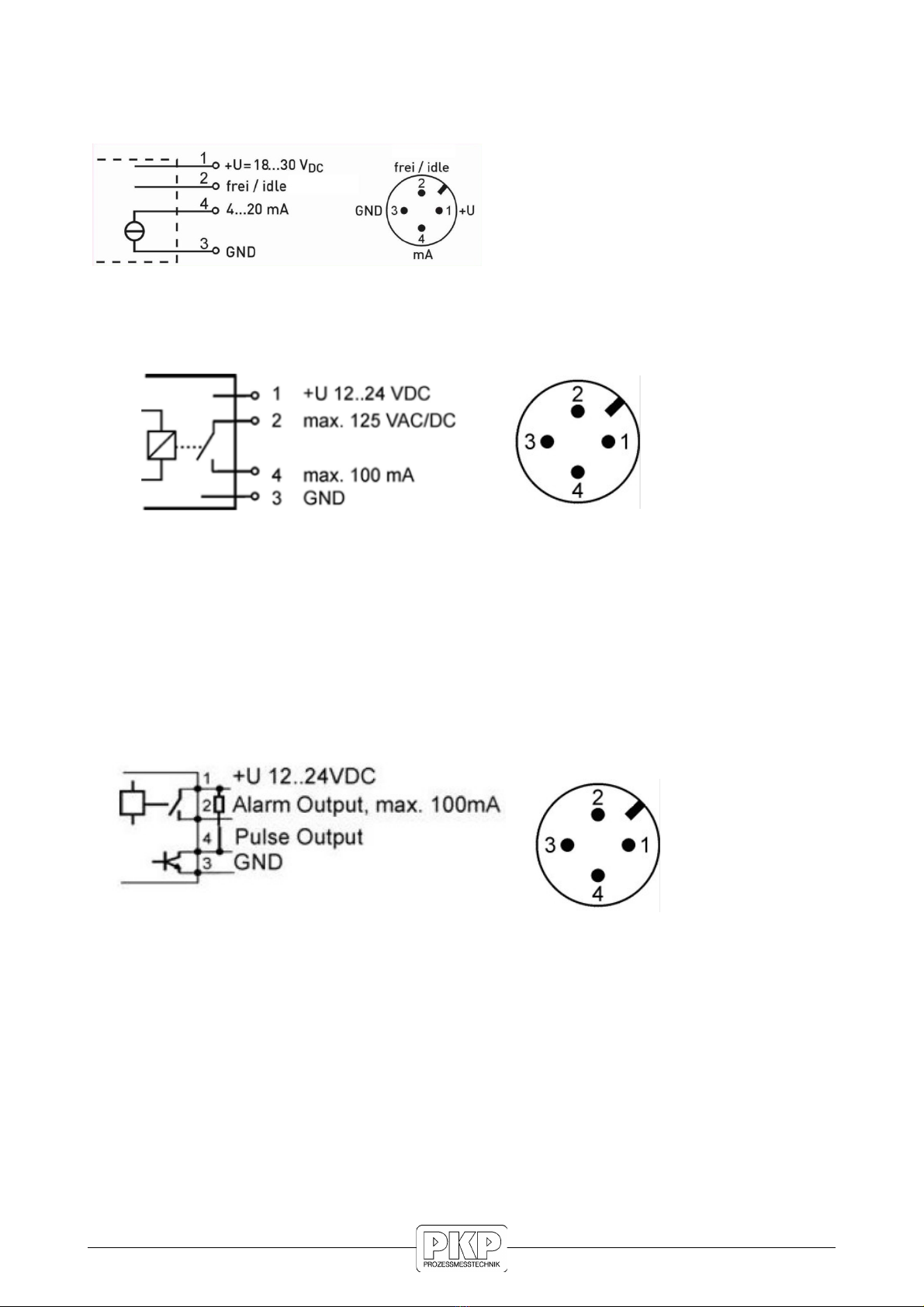

Electrical Connection.............................................................................................................8

Replacement of turbine inserted..........................................................................................11

Adjustment of switching points (for option VE und VEP)....................................................12

Cleaning and Maintenance..................................................................................................14

Technical Data.....................................................................................................................15

Materials in contact with fluid...............................................................................................17

Hall-Sensor (P 10) Output Signal Characteristics.............................................................18

Dimensions..........................................................................................................................19

Safety Information

General Instructions

To ensure safe operation, the device should only be operated according to the

specifications in the instruction manual. The requisite Health & Safety regulations for a

given application must also be observed. This statement also applies to the use of

accessories.

Every person who is commissioned with the initiation or operation of this device must have

read and understood the operating instructions and in particular the safety instructions!

The work safety instructions in this manual as well as the safety, accident prevention and

environmental protection regulations generally valid for the work area must be observed.

The liability of the manufacturer expires in the event of damage due to improper use, non-

observance of this operating manual, use of insufficiently qualified personnel and

unauthorized modification of the device.

roper Usage

The flow meters DR08-25 are designed to monitor continuous flow rates of liquids which

do not attack the device materials. All other usage is regarded as being improper and

outside the scope of the device.

In particular, applications in which shock loads occur (for example, pulsed operation)

should be discussed and checked in advance with our technical staff.

The series DR08-25 flow meter devices should not be deployed as the sole agents to

prevent dangerous conditions occurring in plant or machinery. Machinery and plant need

to be designed in such a manner that faulty conditions and malfunctions do not arise that

could pose a safety risk for operators.

DR08-25 Instruction manual 09/2020 page 2