Models and Measuring Ranges:

Type Measuring

range

[l/min]

iscosity

range

[cSt]

Connection Measuring

volume

[ml/pulse]

Resolution

[pulse/l]

DV01.0 0,02- 4 20…4000 G 1/4 female 0,04 25000

DV01.1 0,25…10 20…4000 G /8 female 0,2 5.000

DV01.2 0,16…16 20… 000 G /8 female 0,245 4.082

DV01. 1…65 20…4000 G /4 female 2 500

DV01.4 1…200 20…4000 G 1 female 5,2 191,5

Material:

Type Housing Gear wheels Bearings

DV01.0A aluminium

anodized

stainless steel

1.4462

ball bearings

DV01.0E stainless steel

1.4404

stainless steel

1.4462

ball bearings

DV01.1A aluminium

(anodized)

steel plastic plain bearings

DV01.1E stainless steel

1.4404

stainless steel

1.4462

plastic plain bearings

DV01.2A aluminium

(anodized)

steel ball bearings

DV01. A aluminium steel multilayer plain bearing

DV01.4A aluminium steel ball bearings

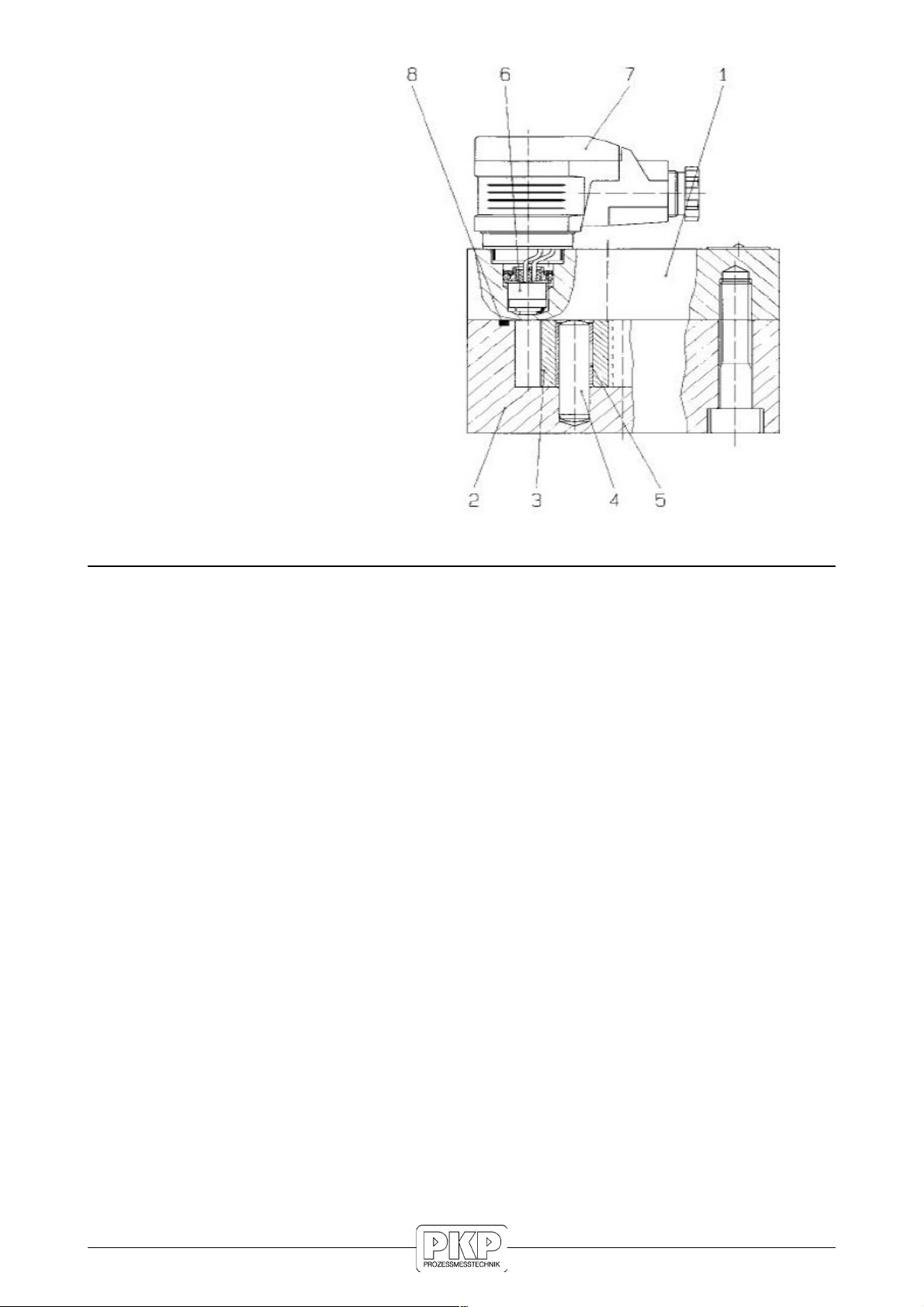

Dimensions:

DV01.0A / DV01.0E: b = 55 mm, t = 55 mm, h = 46 mm

DV01.1A und DV01.1E: b = 55 mm, t = 65 mm, h = 108 mm

(DV01.2A: like DV01.1A, but housing b = 55 mm, t = 65 mm,

h = 108 mm)

DV01. A: b = 90 mm, t = 100 mm, h = 7 mm

DV01.4A: b = 120 mm ; t = 170 mm ; h = 105 mm

Order Code:

Order number: D 01.

Gear wheel flow sensor

1A. 0. 0

Measuring ranges:

0A = 0,02…4 l/min, aluminium

0E = 0,02…4l/min, stainless steel

1A = 0,25…10 l/min, aluminium

1E = 0,25…10 l/min, stainless steel

2A = 0,16…16 l/min, aluminium

A = 1…65 l/min, aluminium

4A = 1…200 l/min, aluminium

Display:

0 = without display

DVA= prepared for plug-on display DVA

(data sheet on the following pages)

Options:

0 = without

1 = please specify in plain text

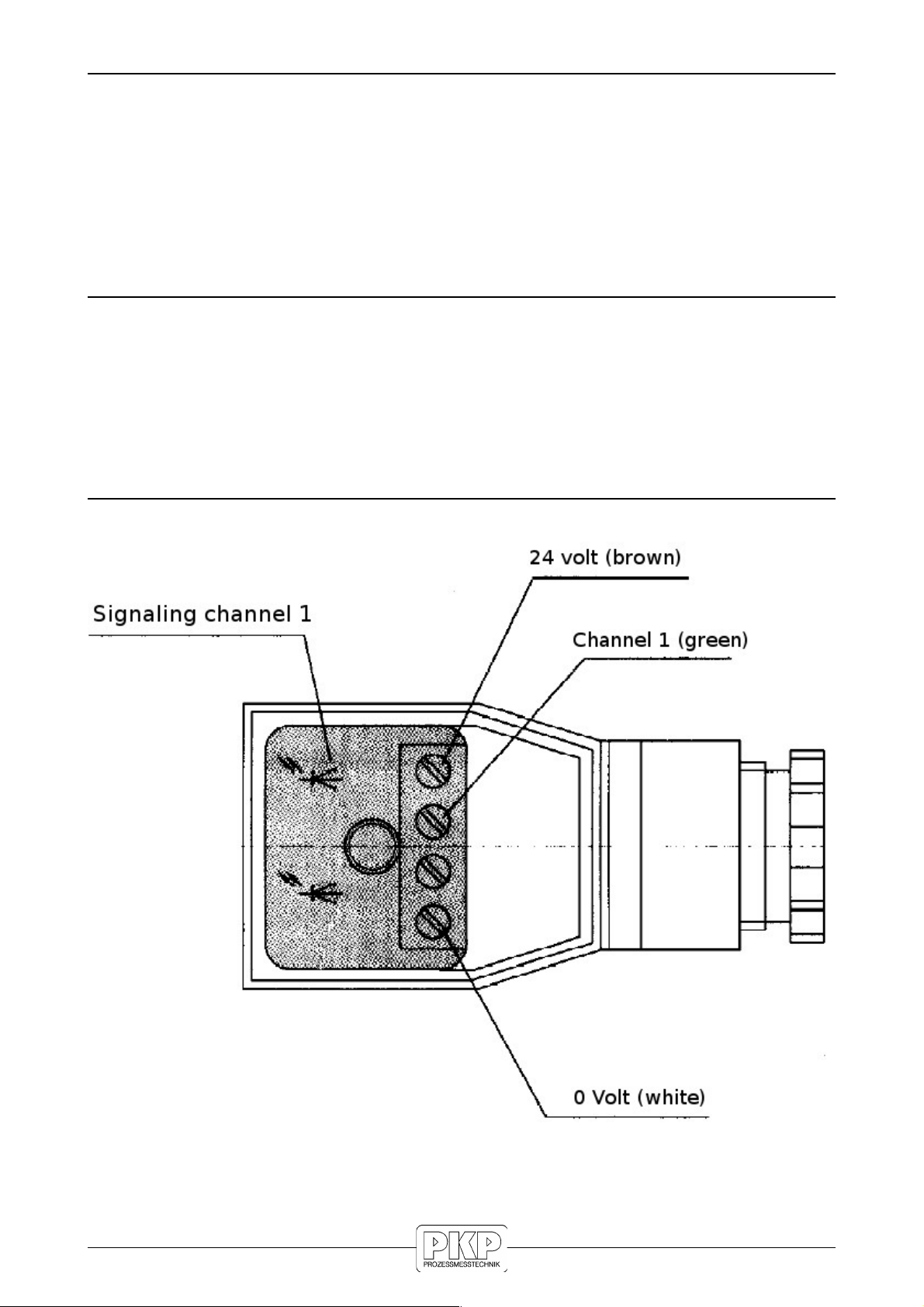

Electrical Connection:

Technical Data:

Max. pressure:

DV01.0A: 200 bar

DV01.0E: 160 bar

DV01.1A and DV01.1E: 160 bar

DV01.2A: 160 bar

DV01. A: 160 bar

DV01.4A: 80 bar

Medium temperature range: −10 °C…+80 °C

Accuracy:

DV01.0A and DV01.0E: ±2 %

DV01.1A and DV01.1E: ± %

DV01.2A: ±0, %

DV01. A: ±2,5 %

DV01.4A: ±1 %

Weight:

DV01.0A and DV01.0E: 0,5 kg

DV01.1A and DV01.1E: 0,5 kg

DV01.2A: 0,7 kg

DV01. A: 1,9 kg

DV01.4A: 6 kg

Supply voltage: 12… 0 VDC,

protected polarity

Power consumption: 0,9 W

Output signal: square wave pulses,

min. 0,8 x UB,

duty cycle

1:1 (±15 %)

Protection class: IP65

PKP Prozessmesstechnik GmbH

Borsigstr. 24 • D-65205 Wiesbaden

S +49 (0) 6122-7055-0 • T +49 (0) 6122 7055-50

Flow