!WARNING SAFE MASONRY WORKS

The masonry works for preparing the ceiling to install the Product must be sturdy and safe and com-

pleted in a workmanlike manner, according to applicable building regulations.

By way of example only, the professional persons charged with completing the masonry works could

be: Construction Engineer, Structural engineer, or a Builder, duly registered in the respective profes-

sional register.

!DANGER WRONG WALL PERFORATION

In case of wrong perforation of the Product supporting wall (e.g., the breakage of a reinforced-

concrete ceiling/wall iron) always inform the building manager as this could aect the stability of the

building.

!WARNING CEILING AND WALL STRUCTURAL CAPACITY

The ceiling must be able to withstand a weight of at least 300 kg/m2 and have a thickness of at least

250 mm. For the wall version, the wall must be a supporting wall and be made of solid brick. Installa-

tion on walls of perforated bricks and plasterboard is only allowed with the tting of another plate on

the opposite side of the wall (sandwich closing).

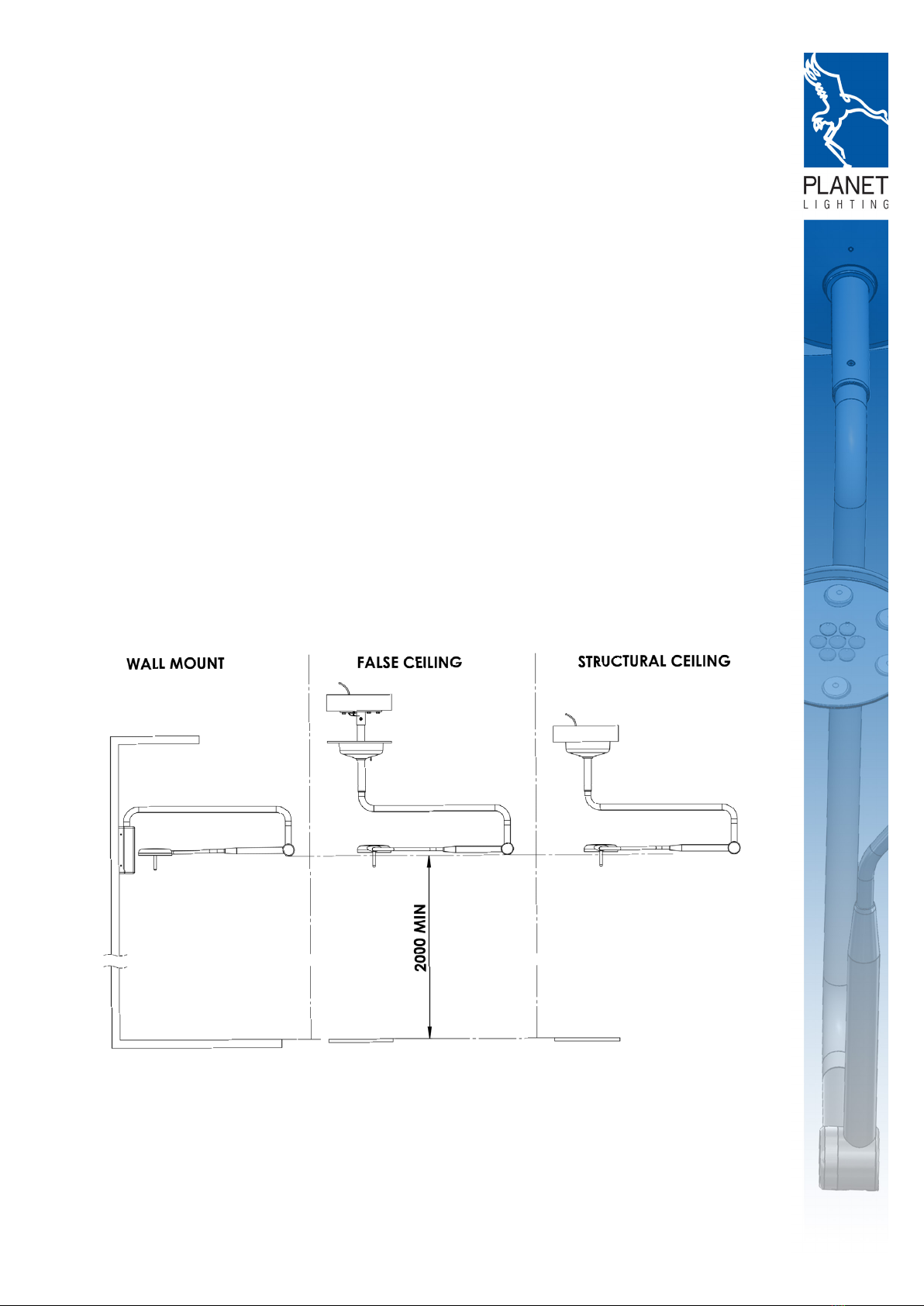

Following are the structural loadings and approx product weights. The listed weights and loads are

static only, and as such do not include any dynamic loads or externally applied loads such as opera-

tor handling. For similar detail, you may also refer to Fig 2.0 for Ceiling, and Fig 15.0 for Wall mount-

ed versions:

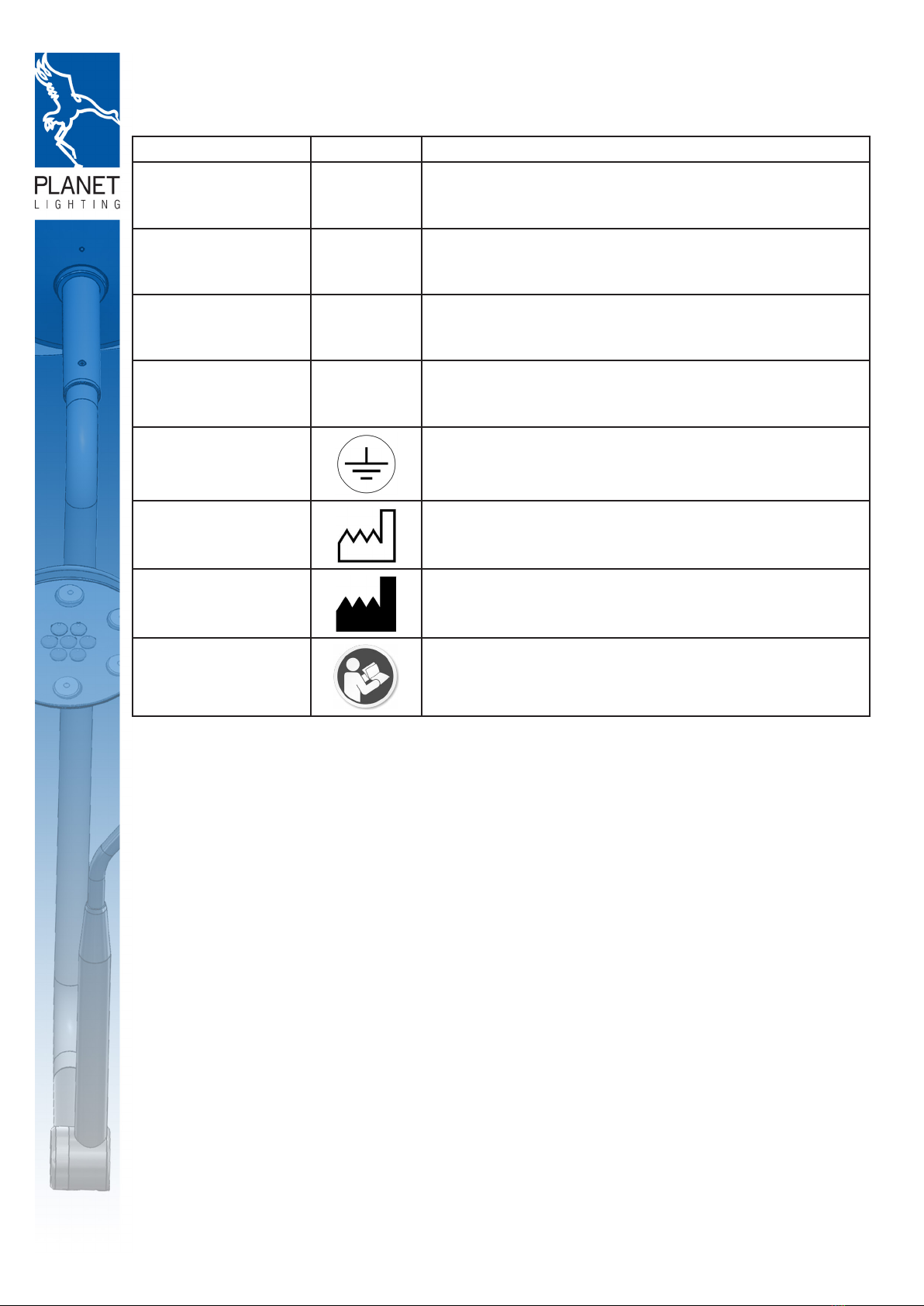

Structural capacity requirements - Ceiling Mounted

Total Mass - structural ceiling tting only: 10.6kg

Mass - arm only: 6.3kg

Torque (at mounting plate): 63Nm

Structural capacity requirements - Wall Mounted

Total Mass - structural ceiling tting only: 10.22kg

Mass - arm only: 6.3kg

Torque (at mounting plate): 69Nm

The Product installation premises must conform to local building standards.

After making sure the premises used for medical purposes are in conformity with the above require-

ments, proceed to mechanically anchor the ceiling and wall plate, assessing the type of building and

making all consequent adaptations.

THE SERVICE PERSONNEL have all technical, civil and legal responsibilities relating to correctly and

suitably performing Product anchoring and installation operations in an adequate manner.

3.2 CORRECTLY WIRING UP THE PREMISES

DANGER SAFE WIRING INSTALLATIONS

The premises used for medical purposes must be safely wired up in a workmanlike manner by SER-

VICE PERSONNEL to power the Product.

DANGER ELECTRICAL ENVIRONMENT IN COMPLIANCE WITH THE LAW

Before installing the Product, the SERVICE PERSONNEL must make sure

the following conditions exist:

• The wiring system of the environment (premises) in which installation is made must conform with

regulations for premises used for medical purposes and with applicable national laws and/or

regulations.

• The electrical system must have a certicate of conformity issued by whosoever installed it.

• The earth system must be certied as required by applicable regulations.