Model ‘ULED’ Spring Balanced Examination Light - Installation & Maintenance Instructions

1.0 INTRODUCTION

This installation and instruction manual describes how to install, maintain and operate the Planet Model

‘ULED’ examination light. Prior to installation carefully read through all the instructions enclosed in this

manual.

If there are any concerns or you do not understand, please contact customer service at Planet Lighting.

WARNINGS

Only qualified electricians can install the Planet model ‘ULED’ light. It is to be direct wired only. Installation

performed by unauthorised personnel could result in personal injury and or equipment damage. Under

no circumstances should any modifications or adjustments, other than those detailed under section 9.0

Maintenance, be made to the Planet Model ULED.

2.0 Product Information

The Planet ULED is a state of the art examination light which utilises cutting edge Solid State Lighting technology

combined with the proven Planet Model U spring arm and bracket system. Designed and manufactured in Australia by

Planet Lighting (established 1911) an R&D driven, exporting designer and manufacturer with over 6 years experience

in the design, manufacture and supply of Solid State Lighting devices worldwide.

The Planet ULED provides an improved working environment, significantly reducing on-going maintenance,

with low operational costs and offers a “greener” alternative to similar products.

The Planet model ULED allows the accurate positioning of the lamp head above any work surface. It is designed to be

mounted on a wall or ceiling and be pulled down from above when required, remaining there until re - positioned.

At Planet we take great pride in the design and production of our lights and we are sure you will derive satisfaction

from owning and using our products. When installed and maintained in accordance with the instructions contained in

this service leaflet, this product will provide many years of trouble free operation.

Should you have any enquiry, comment or special lighting need we would like to hear from you. We back our products

with pride, service and a five year warranty.

2.1.0 Environmental Considerations

2.1.1 Packaging

I box containing a complete ULED lamp with Installation and users manual.

2.1.2 Transport

transport to be carried out by road, while maintaining the following environmental conditions.

Temperature: -15/+60 degrees Celsius

Humidity : 10/75%

Atmospheric pressure(h/Pa) 500/1060

2.1.3 Storage

The devices packaged must be stored (warehoused) in a dry place and as per the same

environmental conditions mentioned above.

2.2.0 Disposal and Recycling Information

The ULED light has been designed, taking into account what the manufacturing components are

made out of. This is to ensure when it reaches its end of life, the disposal method

with the lowest/ least negative impact, on human health and the environment is selected.

Unlike the sources of traditional light, LED’s do not contain mercury, toxic gases, filaments or

fragile parts. Due to the fixture being over 95% recyclable and there being no Bulbs/

Globe changing during the ULED life of 50,000+ hours your environmental footprint will be

significantly reduced.

When your ULED light reaches its end of life, contact Planet lighting or our local agents to learn

about recycling options.The ULED light must be disposed of properly according to local laws and,

regulations.

3.0 PLANNING

Prior to installing the Planet Model ‘ULED’ Ceiling and Wall mounts the following items should be checked and con-

firmed.

3.1.0 Architectural considerations

3.1.1 Ensure appropriate mounting structure behind the wall/ceiling

3.1.2 For structural loadings and appox product weights (refer Fig12)

3.1.3 To confirm ceiling/wall height measurements at the appropriate nominal recommended

height from the floor refer Fig 1 (back page)

3.2.0 Electrical considerations

3.2.1 The Planet Model ‘ULED’ wall and ceiling mount are designed to be direct wired only

3.2.2 240V AC supply is available at the connection points

Made in Australia Exported to the World

Tamarind Drive Bellingen NSW 2454 Australia

Phone + 61 (0)2 6659 5600 Fax + 61 (0)2 66552121

Customer Service can be contacted on the phone number below Mon - Friday 9 am - 5 pm

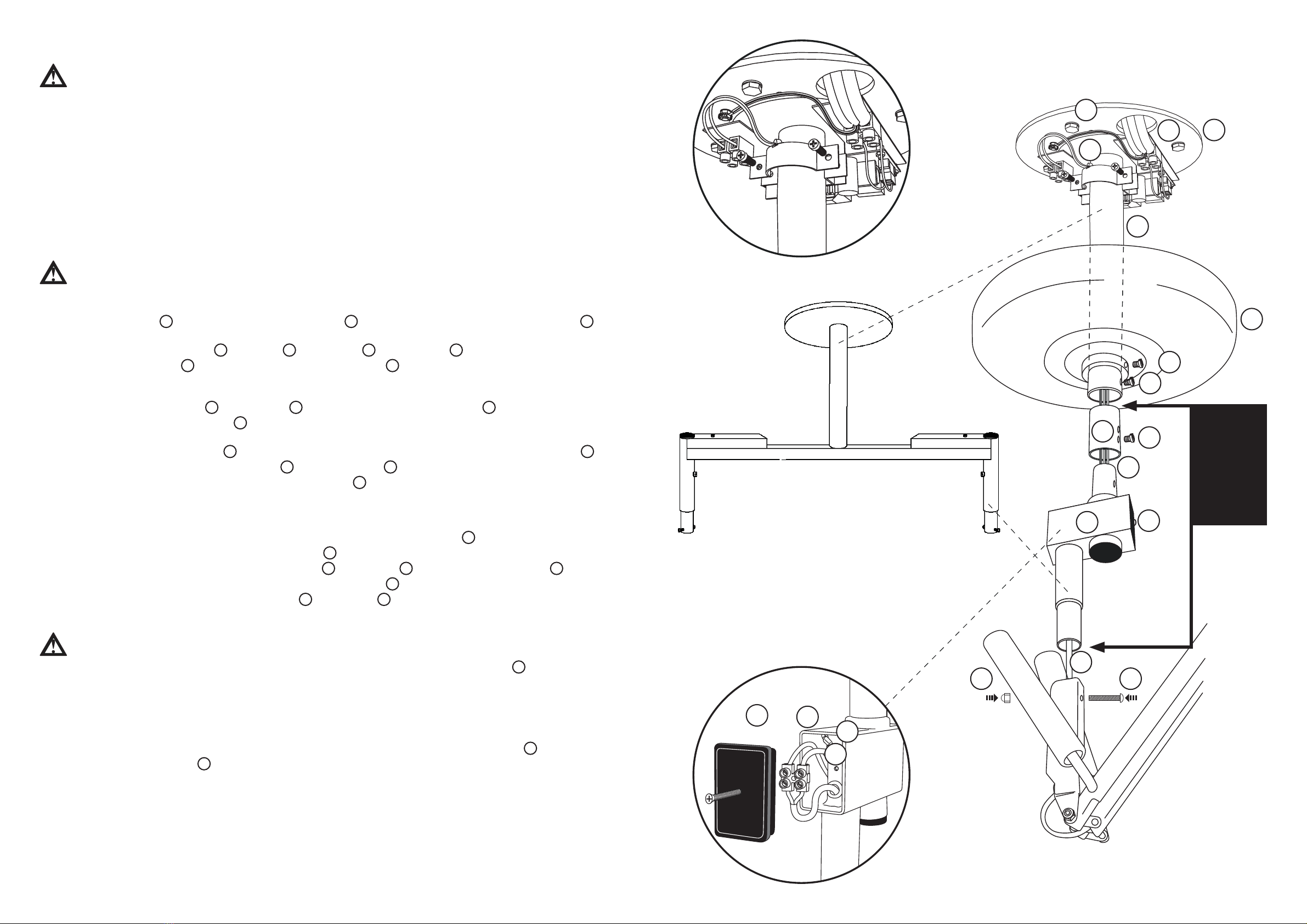

Fig: 12

Recommended

height: 2000 mm

to bottom of lamp pivot

Standard ceiling fix Suspended ceiling fix

Structural ceiling

Recommended

height: 2055 mm

to bottom of

mounting plate

Wall fix

Fig: 1

Recommended

height: 2000 mm

to bottom of swivel head

Ensure

level

Ensure

level

Recommended

height: 2055 mm

to bottom of

mounting plate

610 NOM (= ~16 Nm)

445 NOM (= ~12 Nm)

RELATIVE VERTICAL

MASS: 2.7kg

POSITION SHOWN HERE

IS ESTIMATE ON LY.

(ARM+HEAD ONLY)

Note:

For the purposes of quoting minimum structural requirements of mountings, torque-load of 12 Newton Metres

plus lever-arm effect of length of ceiling-mount tube or wall mounting must be accommodated (plus factors

of safety and dynamic loads). Vertical dead load (IE No dynamic or external loads such as operators pulling or

pushing fitting are included in this value.)

Static weights of complete fixture (Mount, Arm & Light Head)

Wall Mount - 5.5kg

Ceiling Mount - 6.0kg