INSTRUCTIONS

1.1 Principal of Operation

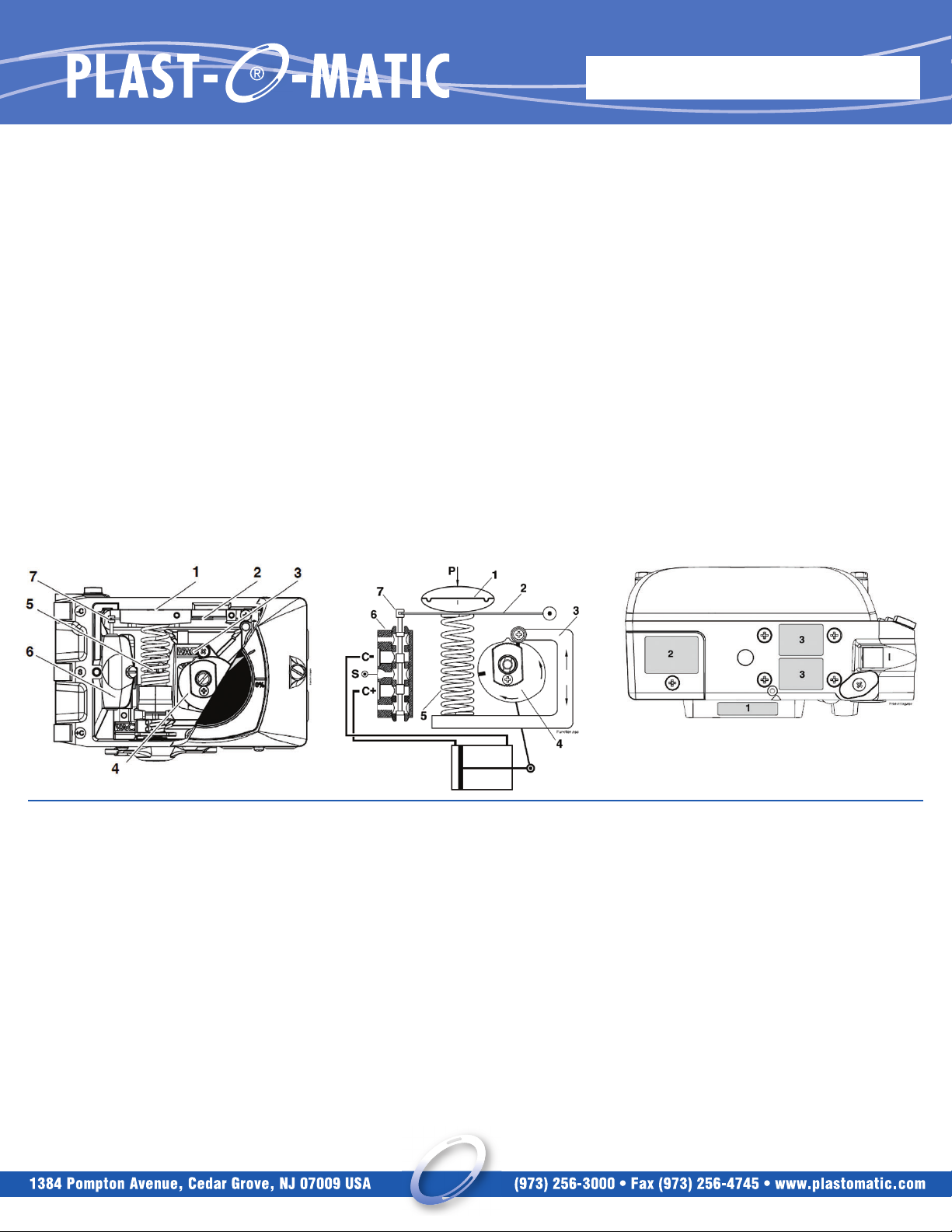

The V200 incorporates the force balance principal of operation. The

desired value, in the form of pressure, affects the membrane (1) with

the force that is created and transferred to the balance arm (2). The

opposing force, which represents the actual control value, is provided

by the feedback spring (5) and creating force in the opposite direction

on the balance arm (2). The feedback spring, resting on the feedback

arm (3), is positioned by the shape and response of the cam. The cam

(4) is connected to the cylinder’s (actuator) piston rod via the drive.

The pilot valve (6) is connected to the balance arm and follows the

balance arm’s movement. The system is stable when the gold plated

spool (7) is in the neutral position and the forces that affect the balance

arm is in equilibrium. As soon as signal change occurs or a change in

the position of the valve/actuator package occurs, the “force balance”

is also changed and the spool responds. Air immediately begins to

flow into the part of the actuator (C+ or C-) which allows the feedback

mechanism to return the spool to the neutral position.

The system is self-stabilizing and searches for a steady state position.

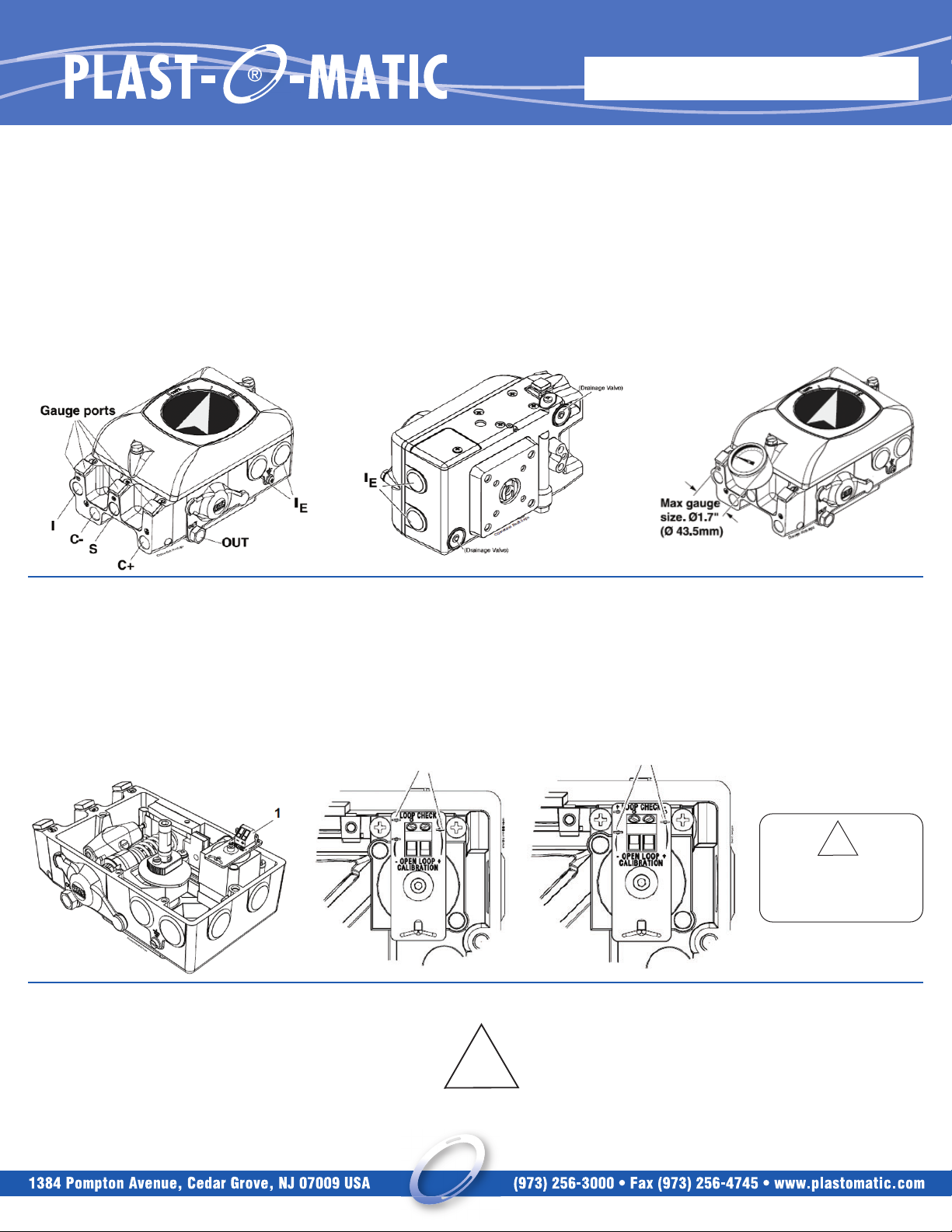

1.2 Product Identification

The V200 identification tags, Serial number tag (1), product model

tag (2) and feedback option tags (3) are placed as shown.

The product model tag contains information on control signal,

maximum working pressure and temperature ranges. Other

information can be shown depending on the model.

ELECTRO-PNEUMATIC POSITIONER

INSTALLATION AND MAINTENANCE

IMPORTANT: READ BEFORE USE

1. INTRODUCTION

Poor air quality is one of the main causes of premature functional

problems with pneumatic and electro-pneumatic equipment. The pilot

valve and IP-converter are precision instruments, and are therefore

the most sensitive parts of the positioner.

a) Water in the supply air is a natural occurrence. This happens when

air is compressed. The compression heats the air and the natural

degree of water in the air can remain as moisture. When the air cools

in pipes etc. the moisture condenses and becomes liquid water. Large

quantities can build and sometimes flood small water separators. This

excess water will eventually reach the control valve and positioner.

This can cause corrosion damage to the IP converter, causing the unit

to malfunction.

We strongly recommend the use of water separators with adequate

capacity. Coalescing filters from a reputable manufacturer is an

inexpensive way to help prevent unit malfunctions or failures, and add

life to the product. These filters remove particles and moisture from

air lines.

b) Oil in the supply air usually is from the main compressor. Oil can

clog the small nozzles and disturb the flapper in the IP-converter. It

can also cause the gold plated spool to “drag” within the pilot valve.

The result is poor control or in the worst case, failure.

c) Particles in the air usually occur because of corrosion. Dirt and

particles can block the small nozzles of the IP-converter. They can

also cause the pilot valve to malfunction. The unit may completely fail.

To ensure normal operational safety with VAC positioner products, we

recommend that a water separator and a <80 micrometer filter are

mounted as close to the product as possible. If large amounts of oil

are present an oil separator should be installed as well.

To further increase operational safety, we recommend that the

working air is clean, dry and free of moisture, water, oil, particles and

other contaminants, in accordance with the standard ANSI/SA –

7.0.01 – 1996.

1.3 Air quality recommendations

EPP-0514-I-1