Table of contents

1 About this document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Applicable Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Product version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Licences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Training of qualified personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Additional information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

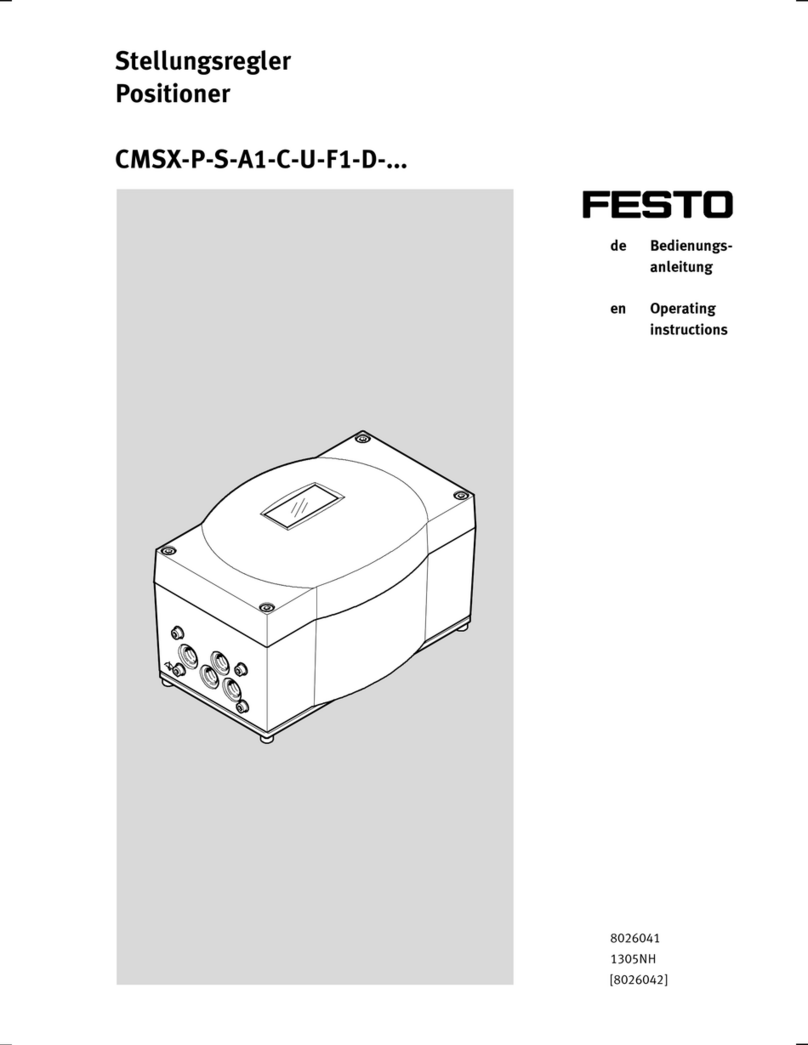

4.1 Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1.1 Product design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1.2 Product variant CMSH-...-V-SD-.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1.3 Operation and display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Safety position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Mounting the pneumatic manifold block CAPS on the CMSH-...-V-SD-.... . . . . . . . . . . . . 18

5.2 Mounting on semi-rotary drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Mounting the shaft adapter on the CMSH-S-.... . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Mounting CMSH-S-VDE1-… on the semi-rotary drive. . . . . . . . . . . . . . . . . . . . . 19

5.2.3 Mounting CMSH-S-VDE2-... on the semi-rotary drive. . . . . . . . . . . . . . . . . . . . 20

5.3 Mounting on linear drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3.1 Mounting CMSH-SE-VDE1-D-… on linear drive DFPI-...-E-NB3 . . . . . . . . . . . . . 23

5.3.2 Mounting CMSH-SE-VDE2-D-… on linear drive DFPI-...-E-NB3VM12 . . . . . . . . 23

5.4 Adjusting position indicator on the CMSH-S-.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Pneumatic installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1.1 Installing the pneumatics of the CMSH-…-VDE1-…. . . . . . . . . . . . . . . . . . . . . . 25

6.1.2 Installing the pneumatics of the CMSH-…-VDE2-…. . . . . . . . . . . . . . . . . . . . . . 25

6.2 Electrical installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Establish electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 Wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.1 Commissioning CMSH-.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.2 Checking and setting parameters in the menu views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.1 Menu structure of the menu views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2.2 ‘Guided setup’ menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2.3 ‘Operation mode’ menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.2.4 ‘Settings’ menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2.5 ‘Initialization’ menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2.6 ‘Identification’ menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57