295867 v.1

Introduction

Plessey’s Hyperion 1750 LED Horticultural Gro light fixture is designed to provide plants ith Photosynthetically

Active Radiation (PAR). This is achieved by supplementing or replacing natural daylight ith an LED generated

light spectrum proven to enhance plant gro th rates and yields. The product is suitable for large scale commercial

greenhouse, hydroponic and research installations and is 1:1 equivalent to a 1000W HPS gro light

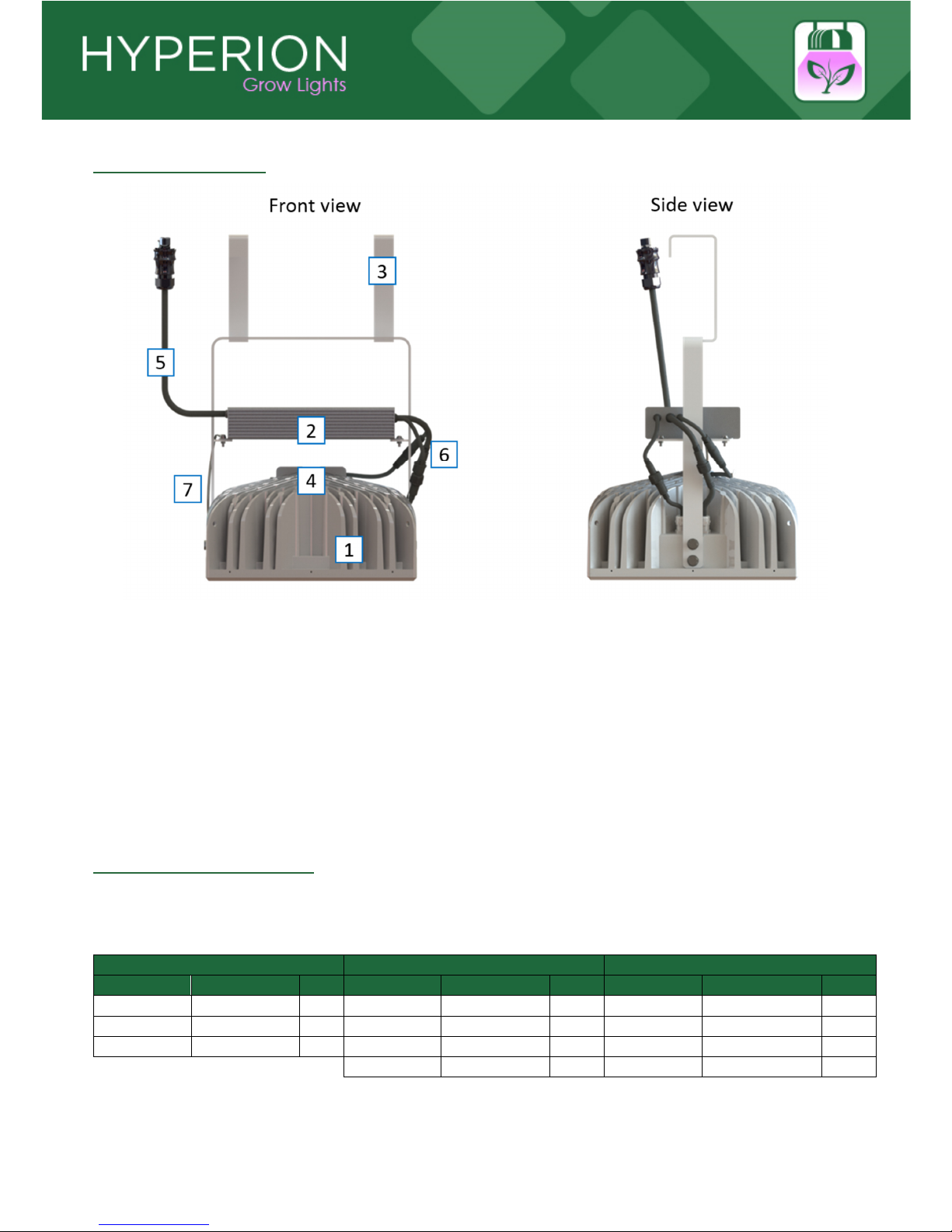

The fixture is constructed from die cast aluminium ith a corrosion proof hite po der coating. The light engine

is made up of state of the art LEDs arranged to maximize output and uniformity. With externally mounted driver

and easily removable fan the fixture has been designed to last and is backed up ith a 5 year/25k hour arranty.

Specification Summary

Notes: @ 400V AC Input Voltage (1)

@ 25°C Ambient (2)

Based on standa d b acket specification. Alte native designs will va y (3)

The values in the table above a e p ovided as typical values, and not a pe fo mance claim specific to any individual p oduct. Pe fo mance will be dependent on

spect um and custome specific options.

Photosynthetic Photon Flux and connected elect ical load a e subject to tole ance of +/- 10%. Fo the pu poses of this document Photosynthetic Photon Flux is

measu ed between 380nm – 780nm with each wavelength weighted equally.

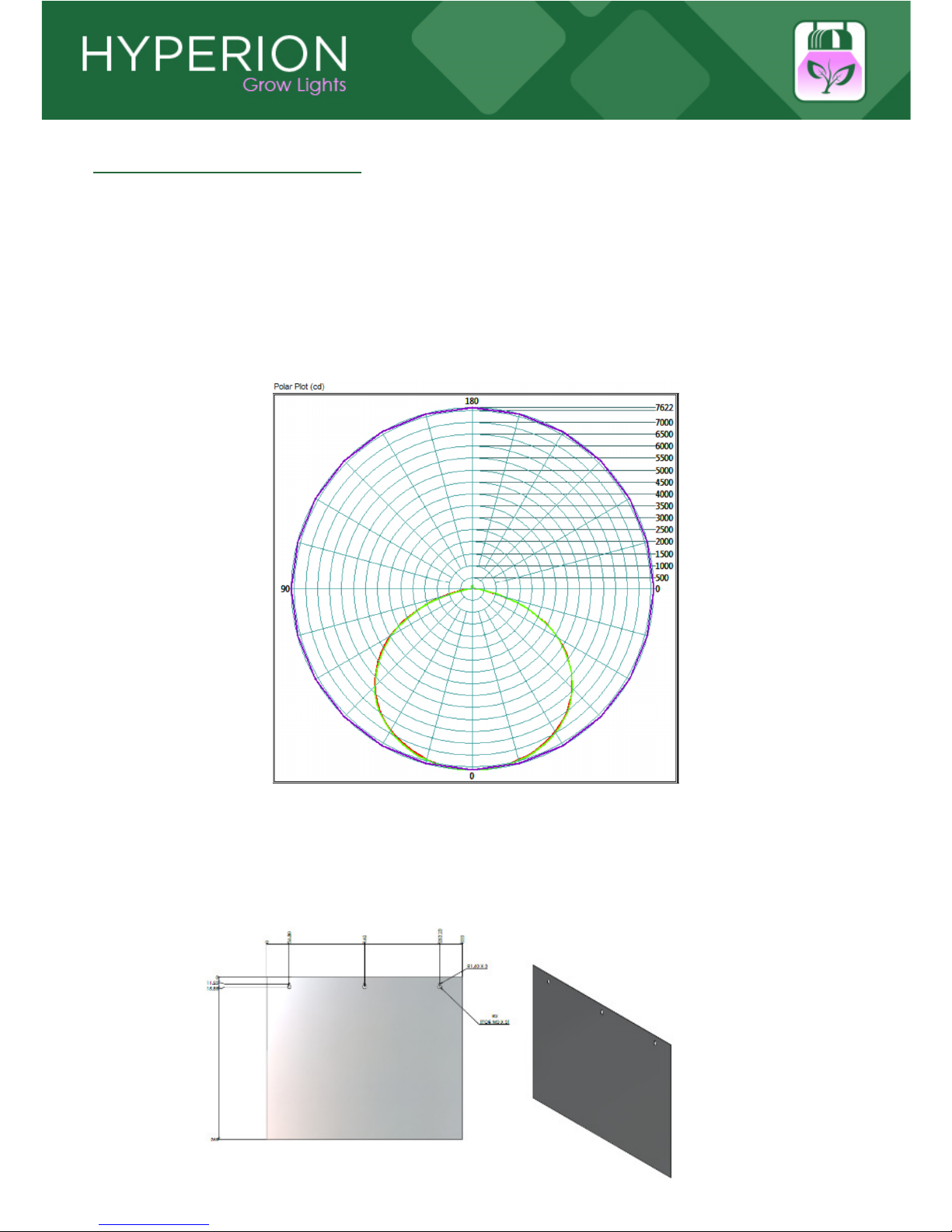

The Hype ion 1750 has been tested by an acc edited independent labo ato y to LM-79-08, (BS) EN 13032-4:2015 and CIE S025:2015 test standa ds. Info mation

can be supplied upon equest.

Safety

The Hyperion fixture does not radiate harmful avelengths of light but like many high po er artificial lights, users

should not look directly at the fixture hilst the light is on.

Care must be taken hen assembling, fitting or handling to prevent personal injury or damage to the product.

This light fitting must be installed by a competent person in accordance ith the local Building and Electrical

Regulations.

Plessey cannot accept any liability for loss, damage or premature failure resulting from inappropriate use. Plessey

can advise on installation requirements including ho to achieve the desired amount of light and uniformity.

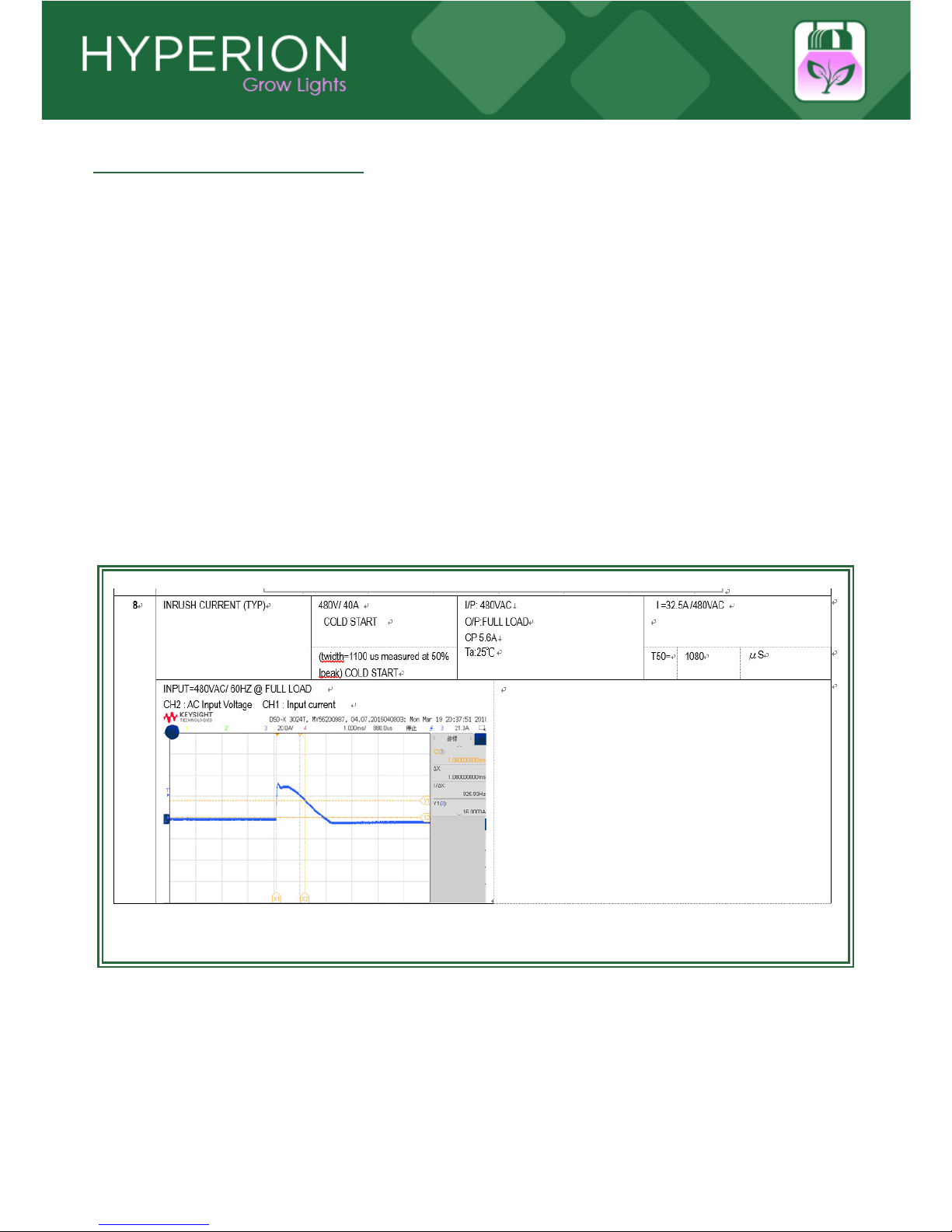

Should the fan fail or the fixtures ability to actively cool be inhibited the LED Printed Circuit Board (PCB) ill run

hotter. This increase in temperature is registered and fed back to the driver. Upon hitting a certain safety

threshold the driver ill reduce the po er to the PCB. This causes a noticeable drop in light output to approx.

1000umol/s depending on spectrum and protects the fixture from overheating. The driver has a built-in thermal

protection so should it overheat the po er ill be cut.

Value Data