3

TABLE OF CONTENTS

1. SAFETY...................................................................................................................................................... 4

2. GENERAL.................................................................................................................................................. 5

3. BASIC INFORMATION STR...................................................................................................................... 6

4. OPERATING THE STR.............................................................................................................................. 8

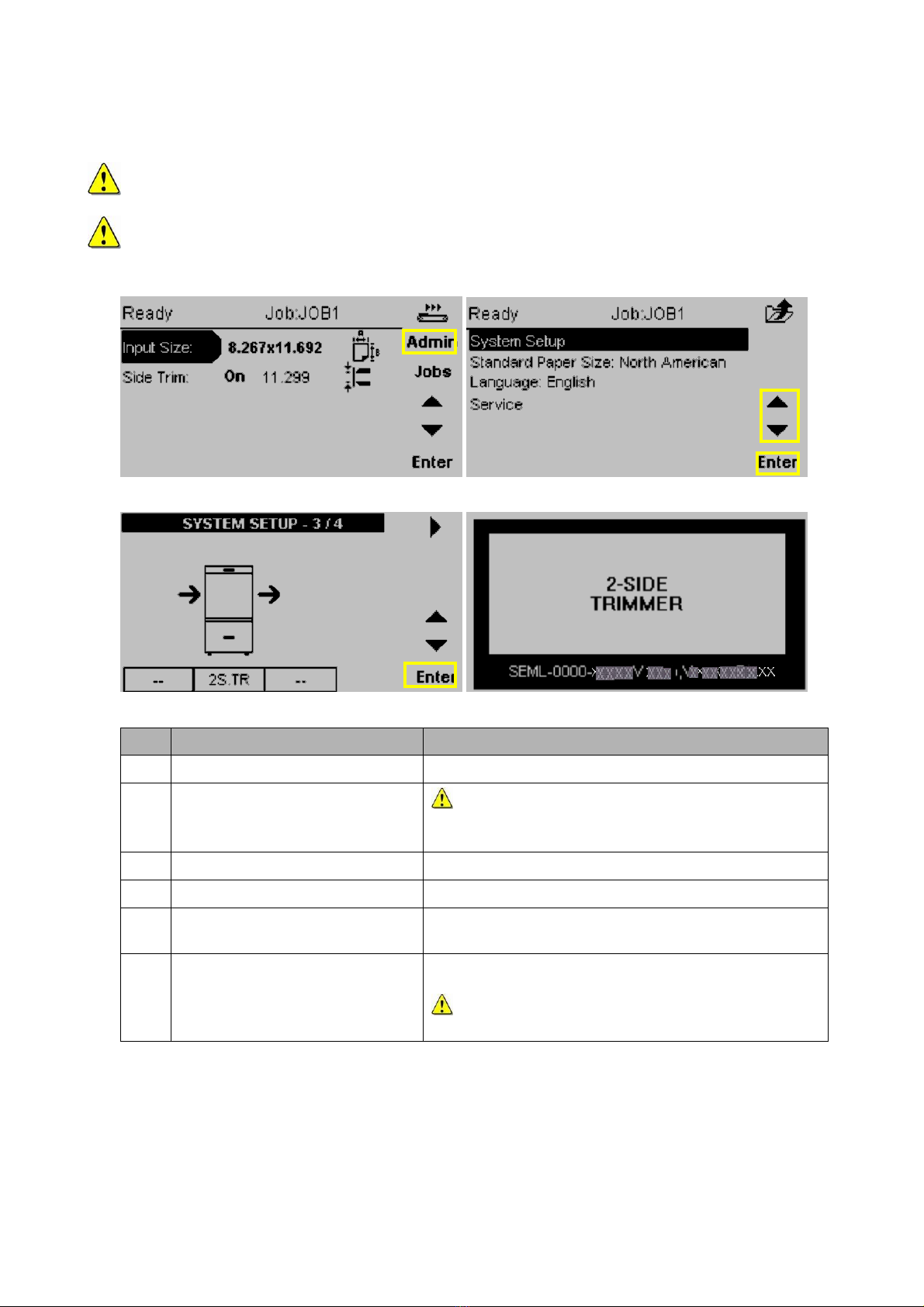

4.1 SYSTEM SETUP ......................................................................................................................................... 8

4.2 LANGUAGE ................................................................................................................................................ 9

4.3 JOB SETUP.............................................................................................................................................. 10

4.4 PAPER SIZE SETUP .................................................................................................................................. 11

4.5 JOB SETUP .............................................................................................................................................. 12

4.6 PAPER INPUT SIZE SETUP ........................................................................................................................ 13

4.7 SIDE TRIM ON /OFF ............................................................................................................................... 14

4.8 CENTRE OFFSET ..................................................................................................................................... 15

4.9 PURGE BUTTON ....................................................................................................................................... 16

5. TROUBLESHOOTING............................................................................................................................. 17

5.1 TRIM WASTE BIN FULL ............................................................................................................................. 17

5.2 CLEARING A PAPER JAM .......................................................................................................................... 18

5.2.1 Warnings / Cautions ..................................................................................................................... 18

5.2.2 Clearing jams inside ..................................................................................................................... 18

5. TROUBLESHOOTING (CONTINUED)....................................................................................................... 20

5.3 STOP IF BOOKLET IS TOO THICK................................................................................................................. 20

6. CLEANING / MAINTENANCE................................................................................................................. 21

6.1 GENERAL ................................................................................................................................................ 21

6.2 CLEANING THE BELTS............................................................................................................................... 21

6.3 REMOVING TRIM WASTE FROM WASTE AREA .............................................................................................. 22

7. TECHNICAL INFORMATION .................................................................................................................. 23