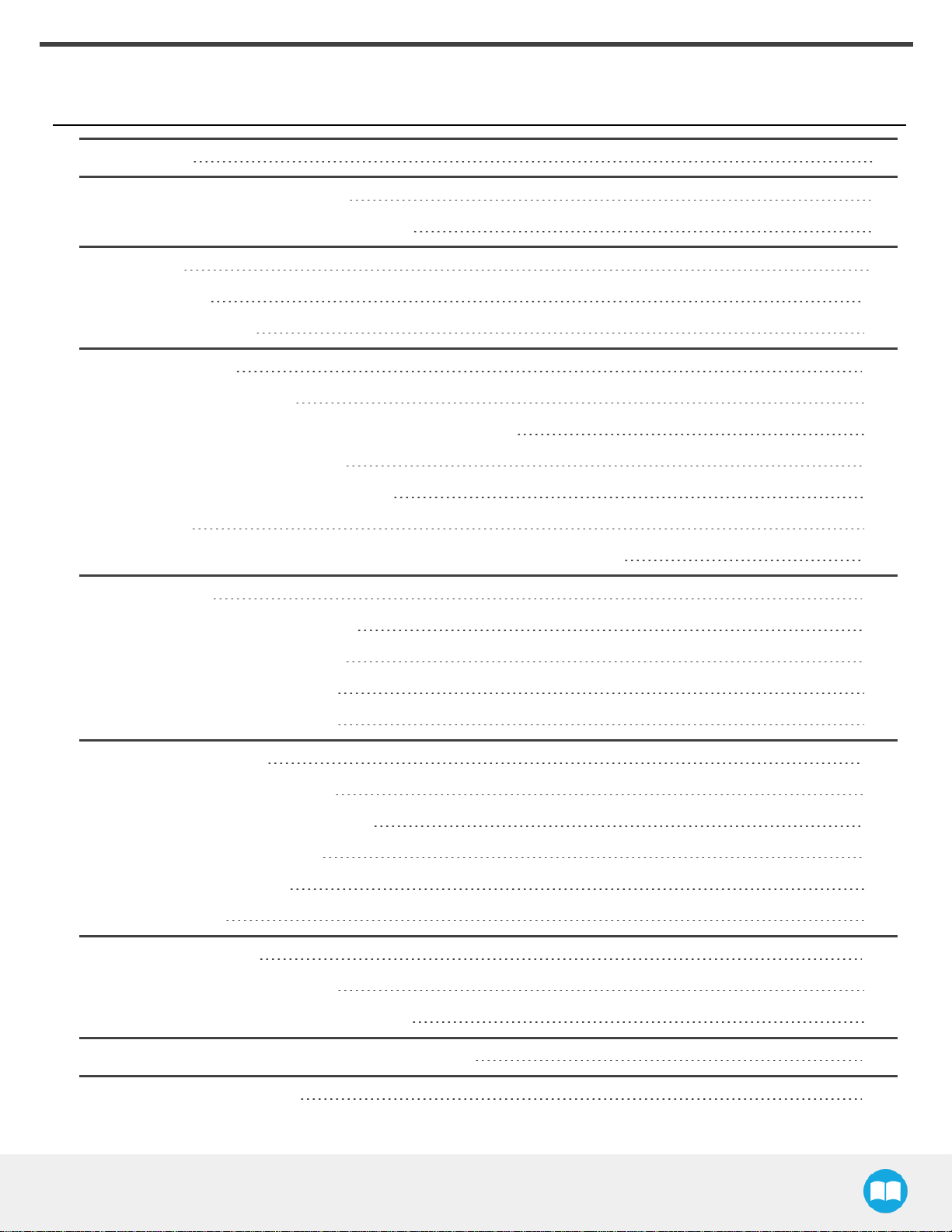

Table of Contents

Revisions 4

1. GeneralPresentation 6

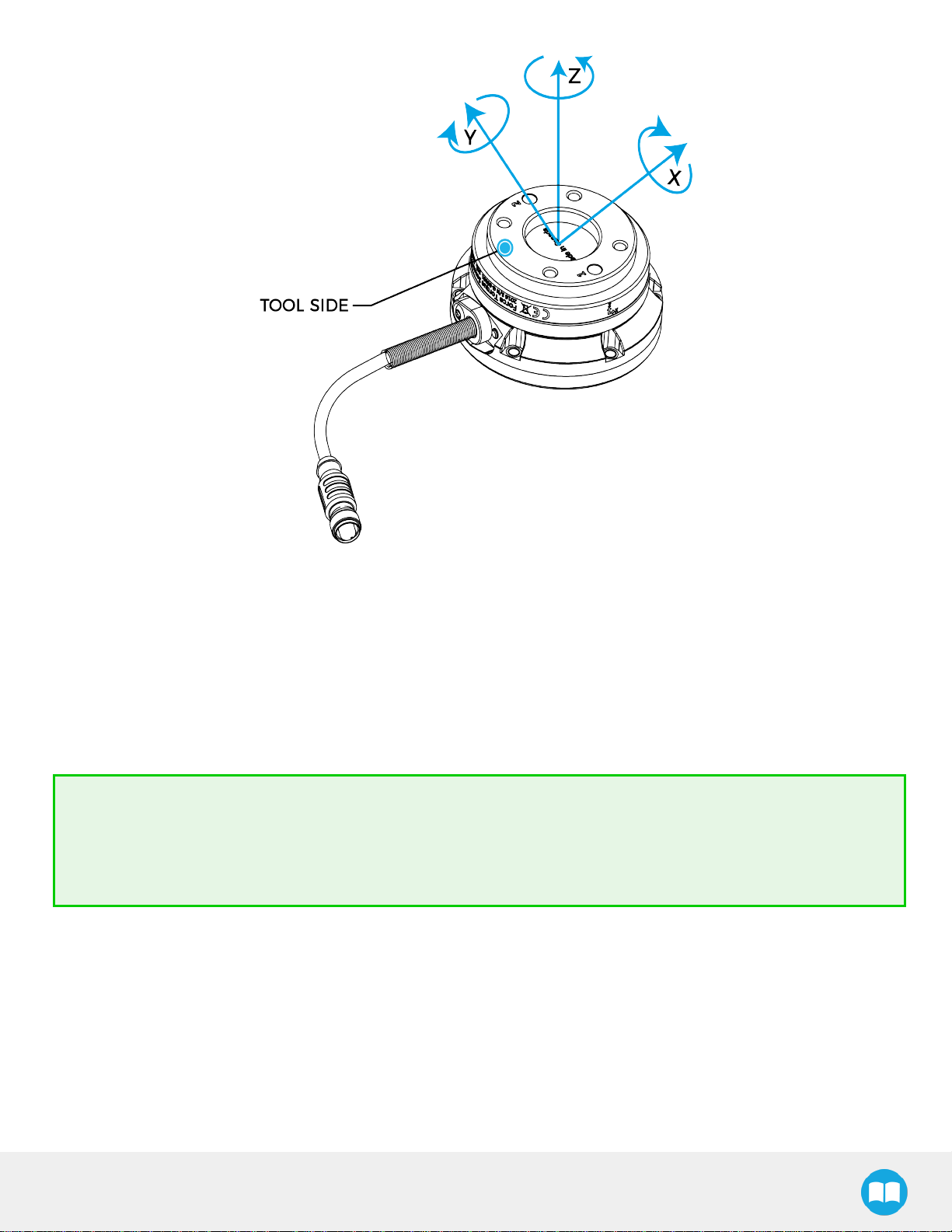

1.1. FT300-SForce TorqueSensor 6

2. Safety 9

2.1. Warning 10

2.2. Intended Use 11

3. Installation 12

3.1. Scope of Delivery 12

3.2. Environmentaland Operating Conditions 13

3.3. MechanicalInstallation 14

3.4. PowerSupplySpecifications 16

3.5. Wiring 17

3.6. CalibrationProcedure forVisualDemo Software (PC) 20

4. Software 21

4.1. Use inTMFlowSoftware 21

4.2. Development Package 25

4.3. VisualDemo Software 29

4.4. SerialCommunication 30

5. Specifications 36

5.1. TechnicalDimensions 36

5.2. MechanicalSpecifications 38

5.3. SignalSpecifications 41

5.4. ElectricalRatings 42

5.5. Couplings 42

6. Maintenance 44

6.1. Maintenance Intervals 44

6.2. Cable replacement procedure 45

7. Spare Parts, Kitsand Accessories 46

8. Troubleshooting 47

FT 300-SForceTorqueSensor-InstructionManual

2