Electric TV Lift, VL-PLA-ST2-ST3

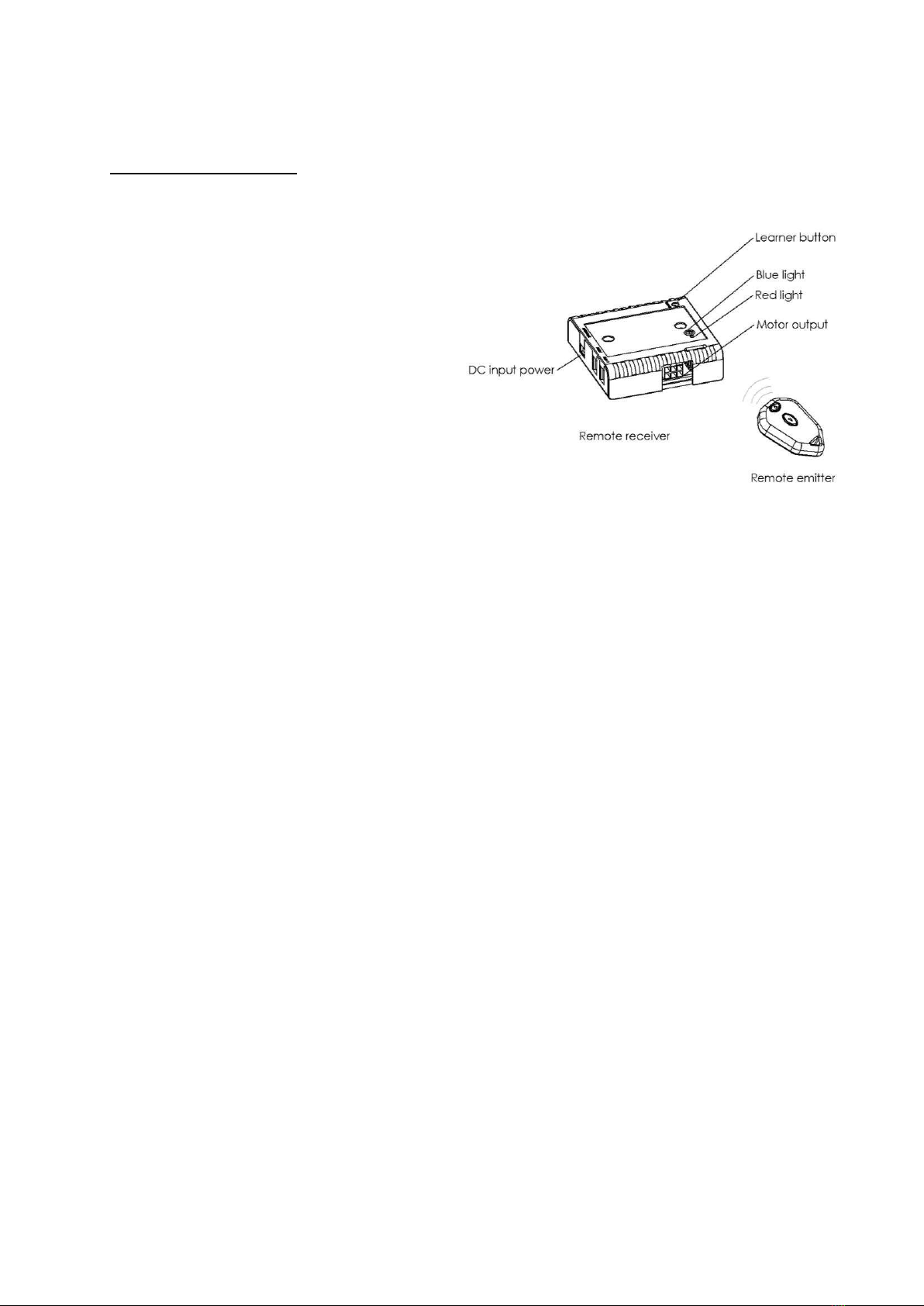

6. RF remote system.

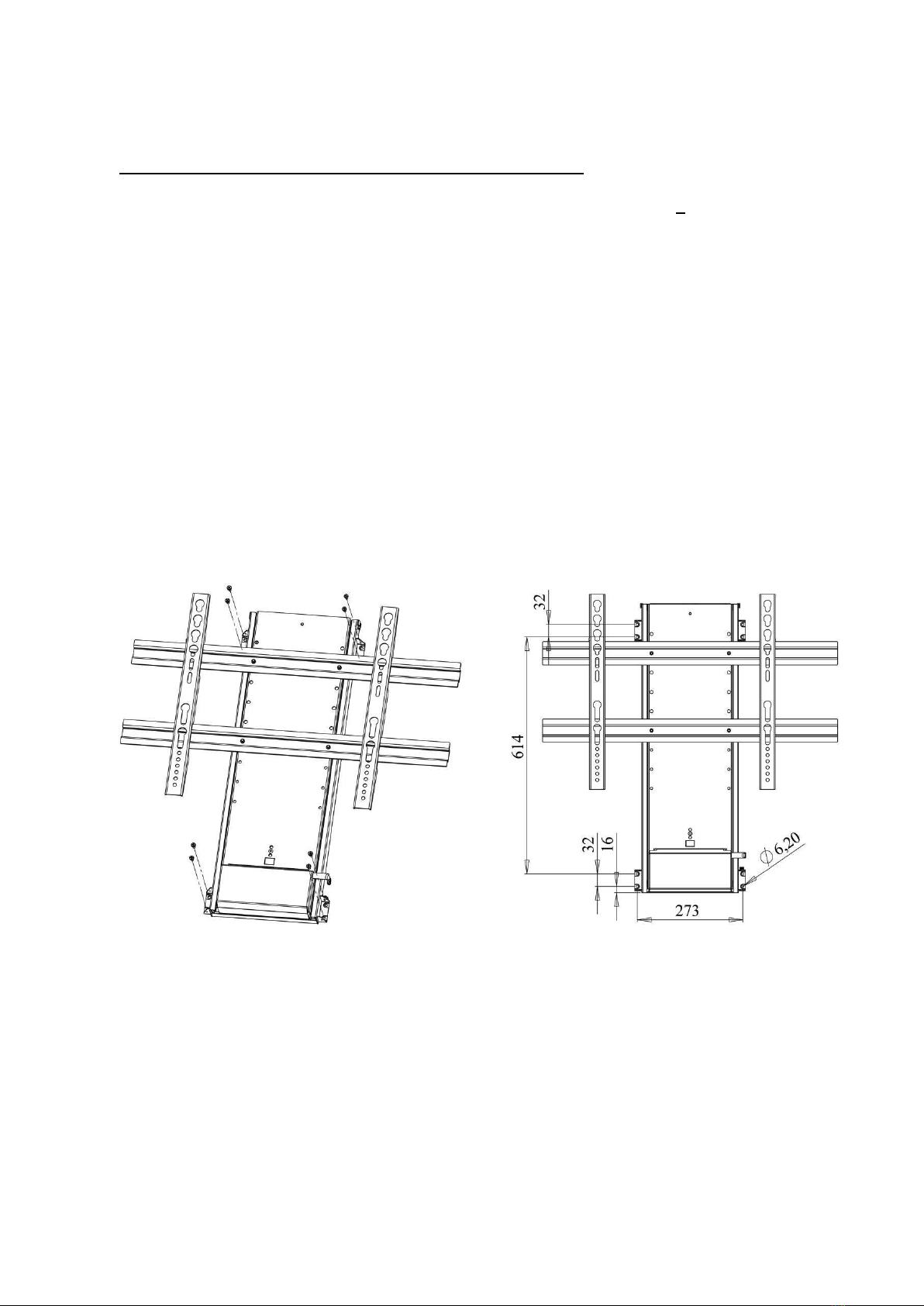

Installation

o connect the power supply and

the motor unit to the remote re-

ceiver. 2 different plug sizes

make this connection only possi-

ble to make in the right way

o after having connected the plugs,

the blue light will be lit

o push the emitter buttons and the

motor unit will move up and down

o for stopping the motion one of the

buttons need to be pushed again

Learning

o if the remote receiver does not respond when pushing the emitter buttons, reset the

receiver. After that, code the emitter and receiver together again.

o it is possible to code up to 10 remote emitters to the remote receiver.

Coding

o push the learner button on the receiver for less than 1 sec.

o push one of the emitter buttons

o the red light will start flashing

o push one of the emitter buttons again and the red light will turn off

o the units now are coded together with a unique code

Reset

o push and hold down the learner button on the receiver for 10 sec. (will be reset when

the red light start to blink).

External rocker switch

o the external rocker switch #9 can be connected to the receiver, if a fixed operation

unit is required. This should always be fitted or accessible in case the RF handset or

battery fails.

Trouble shooting

o check the plug connections

o check whether the blue light is on

o reset the receiver and make a new coding

o always test the lift on the manual rocker switch

o see www.venset.com , click “support”

10