ACCESSORIESACCESSORIES 77

buretor runs dry.buretor runs dry. NOTE: ThisNOTE: This operation aidsoperation aids inin

preventingpreventing the carburetor from being con-the carburetor from being con-

taminated with gums thattaminated with gums that normally formnormally form inin

gasolinegasoline as a result of prolonged exposure toas a result of prolonged exposure to

oxygen in the air.oxygen in the air.

(3) Remove spark plugs and pour two ounces of(3) Remove spark plugs and pour two ounces of

Crankcase Detergent and Rust Inhibitor into each cyl-Crankcase Detergent and Rust Inhibitor into each cyl-

inder through spark plug openings. Turn the engineinder through spark plug openings. Turn the engine

several revolutions with starter to distribute oil on theseveral revolutions with starter to distribute oil on the

cylinder walls, and reinstall spark plugs.cylinder walls, and reinstall spark plugs.

(4) Remove cylinder head covers. Using a clean(4) Remove cylinder head covers. Using a clean

paint spray gun with dry air, coat rocker arms andpaint spray gun with dry air, coat rocker arms and

shaft, valve springs, push rods and valve stems withshaft, valve springs, push rods and valve stems with

Crankcase Detergent and Rust Inhibitor.Crankcase Detergent and Rust Inhibitor.

STORAGE FOR 60 DAYS OR MORESTORAGE FOR 60 DAYS OR MORE is con-is con-

sidered long term, requiring additional preparation.sidered long term, requiring additional preparation.

The The following following procedure procedure is is very very important.important.

(1) Protect engine and fuel system as outlined(1) Protect engine and fuel system as outlined

above inabove in STORAGE OVER 30 DAYS,STORAGE OVER 30 DAYS, steps 1steps 1

through 4. The car should be completely lubricatedthrough 4. The car should be completely lubricated

and the fluid checked in the transmission, rear axleand the fluid checked in the transmission, rear axle

and steering gear for recommended level. For great-and steering gear for recommended level. For great-

est protection car should not be moved or operatedest protection car should not be moved or operated

after preparations are completed.after preparations are completed.

(2) Place car on blocks to relieve weight on tires.(2) Place car on blocks to relieve weight on tires.

Replace missing valve caps, clean oil or grease fromReplace missing valve caps, clean oil or grease from

tires and maintain recommended inflation pressure.tires and maintain recommended inflation pressure.

NOTE: If car cannot be blocked up, checkNOTE: If car cannot be blocked up, check

tire pressure frequently and maintain attire pressure frequently and maintain at

recommended pressure.recommended pressure. Avoid weight on tires onAvoid weight on tires on

one position only. Do not store near direct sunlight orone position only. Do not store near direct sunlight or

other heat sources. Painting tires does not provide pro-other heat sources. Painting tires does not provide pro-

tection against deterioration. Do not store cars neartection against deterioration. Do not store cars near

electrical devices such as motors or switches. Theseelectrical devices such as motors or switches. These

are an active source of are an active source of ozone, a major cause of rubberozone, a major cause of rubber

aging and checking. The same applies to gasolineaging and checking. The same applies to gasoline

and lubricants, which emit rot-producing vapors.and lubricants, which emit rot-producing vapors.

(3) Check and fill the master cylinder if necessary,(3) Check and fill the master cylinder if necessary,

to the proper level with Super Brake Fluid. Work theto the proper level with Super Brake Fluid. Work the

brake pedal several times every 20 to 30 days to avoidbrake pedal several times every 20 to 30 days to avoid

sticking of cylinder pistons and cups.sticking of cylinder pistons and cups.

(4) Block standard transmission clutch pedal down(4) Block standard transmission clutch pedal down

to the floor board in a completely released positionto the floor board in a completely released position

to avoid the clutch disc sticking to the flywheel or pres-to avoid the clutch disc sticking to the flywheel or pres-

sure plate.sure plate.

(5) Remove the battery-check and recharge if(5) Remove the battery-check and recharge if

the specific gravity is 1.230 or less. Place in storagethe specific gravity is 1.230 or less. Place in storage

and recharge every 30 days to prevent sulphation. Beand recharge every 30 days to prevent sulphation. Be

sure the electrolyte level covers the plates. To avoidsure the electrolyte level covers the plates. To avoid

freezing, the temperature in the storage area shouldfreezing, the temperature in the storage area should

be maintained above 32 degrees F.be maintained above 32 degrees F.

(6) Close windows and other openings regardless of(6) Close windows and other openings regardless of

whether the car is stored outdoors or indoors to pre-whether the car is stored outdoors or indoors to pre-

vent entry of dust. Cover exposed bright surfaces in-vent entry of dust. Cover exposed bright surfaces in-

cluding body mouldings, door handles, name plates,cluding body mouldings, door handles, name plates,

medallions, etc. with Chromium Protector Wax. If waxmedallions, etc. with Chromium Protector Wax. If wax

is accidentally applied over paint, it can be removedis accidentally applied over paint, it can be removed

by wiping with a soft lint-free cloth dampened withby wiping with a soft lint-free cloth dampened with

white unleadedwhite unleaded gasoline.gasoline.

(7) Remove the factory-installed plastic seat covers(7) Remove the factory-installed plastic seat covers

to prevent the possibility of staining the upholstery dueto prevent the possibility of staining the upholstery due

to condensation. If it is necessary to store cars out-to condensation. If it is necessary to store cars out-

doors, cover seat cushions and backs with heavydoors, cover seat cushions and backs with heavy

paper to prevent fading from sunlight. This also appliespaper to prevent fading from sunlight. This also applies

to inside storage if the car interior is partially exposedto inside storage if the car interior is partially exposed

to sunlight. Protect from extremely strong sunlight byto sunlight. Protect from extremely strong sunlight by

taping heavy paper over all windows.taping heavy paper over all windows.

NOTE: When a car is removed from storage,NOTE: When a car is removed from storage,

it will not be necessary to remove the deter-it will not be necessary to remove the deter-

gent oils previously installed in the engine.gent oils previously installed in the engine.

This oil is a lubricant and will readily mixThis oil is a lubricant and will readily mix

with engine oil.with engine oil.

GROUP 1GROUP 1

ACCESSORIESACCESSORIES

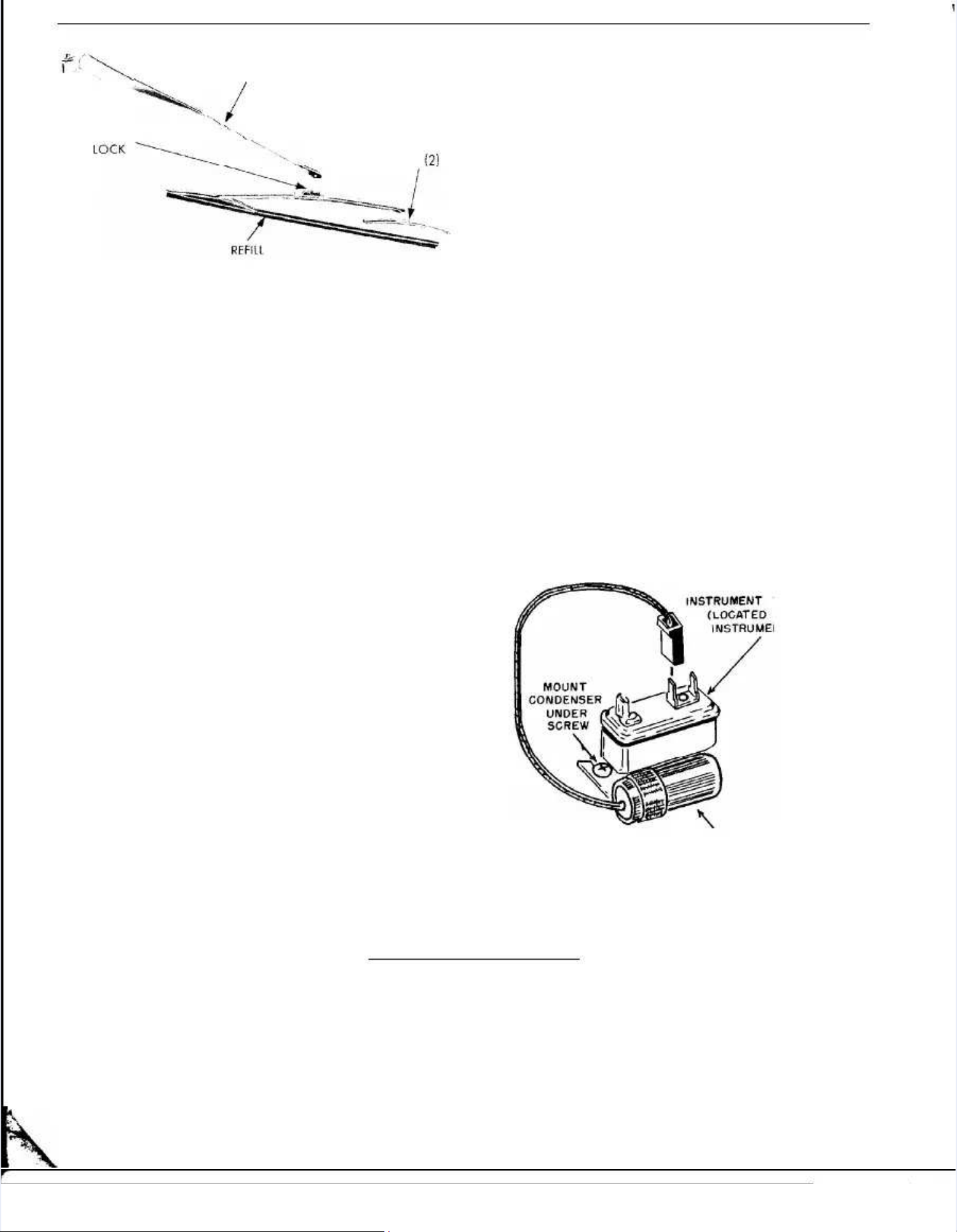

The The windshield windshield wiper wiper is is equipped equipped with with blades blades thatthat

have a replaceable rubber filler, when the rubber ishave a replaceable rubber filler, when the rubber is

deteriorated, it is no longer necessary to replace thedeteriorated, it is no longer necessary to replace the

complete blade assembly.complete blade assembly.

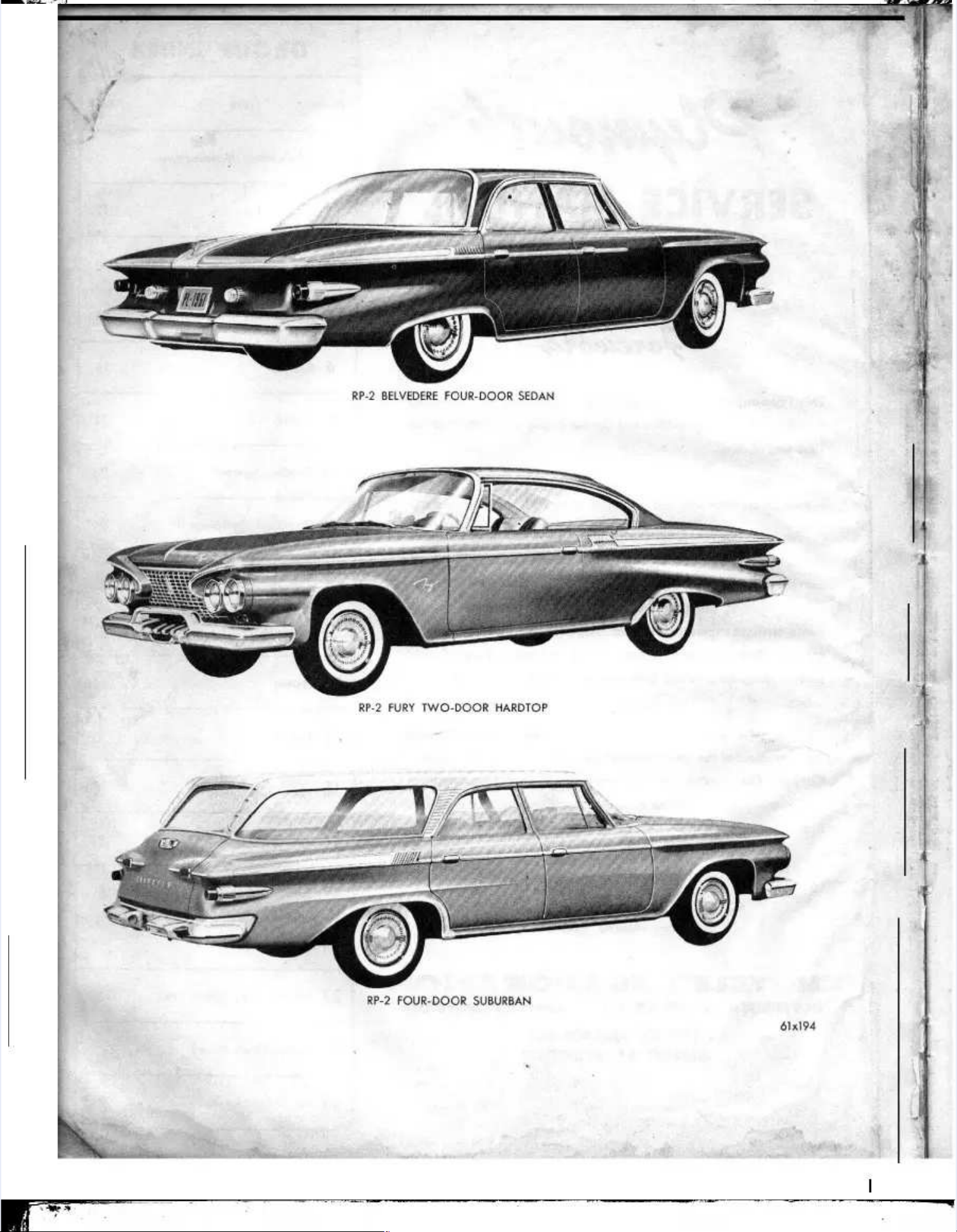

All other accessories installed on 1961 PlymouthAll other accessories installed on 1961 Plymouth

cars remain the same as those used on the 1960 models.cars remain the same as those used on the 1960 models.

Complete servicing procedures can be obtained byComplete servicing procedures can be obtained by

referring to the 1960 Plymouth Service Manual.referring to the 1960 Plymouth Service Manual.

1. WINDSHIELD WIPER ‘BLADE1. WINDSHIELD WIPER ‘BLADE

FILLER REPLACEMENTFILLER REPLACEMENT

RemovalRemoval

( 1) Raise the wiper blade approximately 6 inches( 1) Raise the wiper blade approximately 6 inches

from the windshield and tilt the blade to expose thefrom the windshield and tilt the blade to expose the

arm and blade lock under the wiper arm (Fig. 1).arm and blade lock under the wiper arm (Fig. 1).

(2) Depress the lock lever and disengage the blade(2) Depress the lock lever and disengage the blade

assembly from the wiper arm.assembly from the wiper arm.