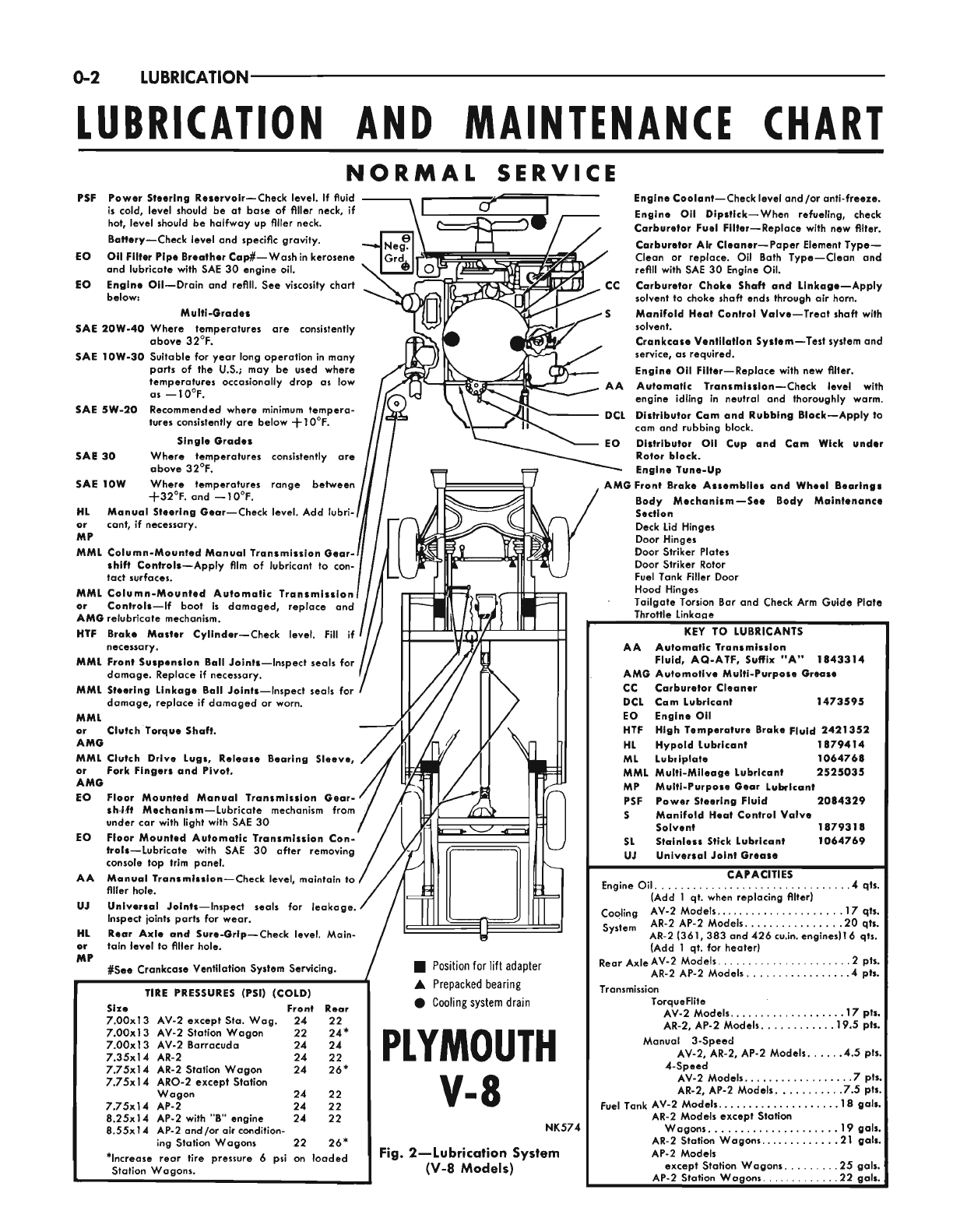

0-2

LUBRICATION

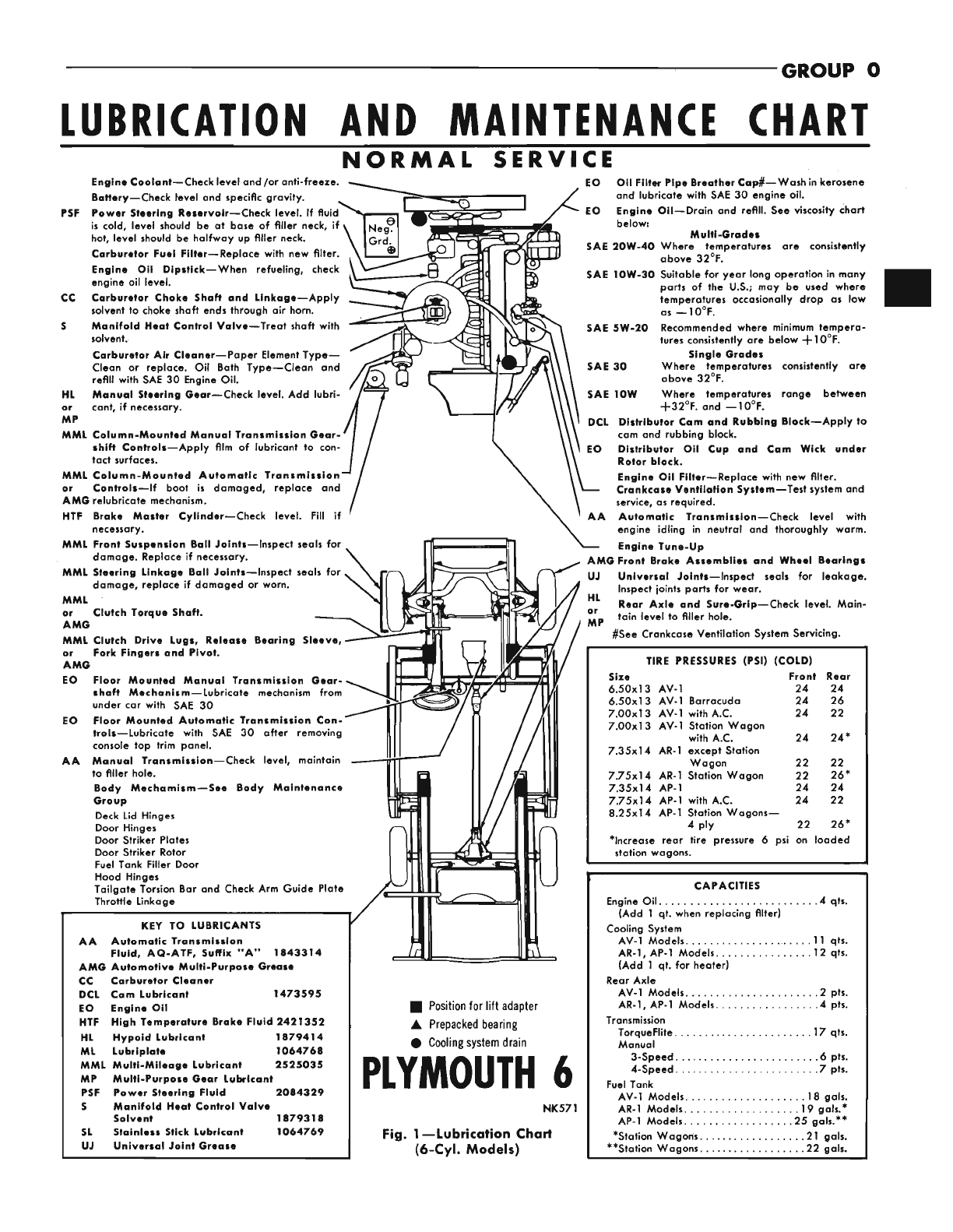

LUBRICATION AND MAINTENANCE CHART

NORMAL SERVICE

PSF Power Steering Reservoir-Check level.

If

fluid

is

cold, level should be at base of filler neck, if

hot, level should be halfway up flller neck.

Battery-Check level and specific gravity.

Oil

Filter

PipeBreatherCap#- Washinkerosene

and lubricate with SAE 30 engine oil.

below:

EngineCoolant-Check level and/or anti-freeze.

Engine

Oil

Dlpstlck-When refueling, check

Corburetor Fuel Filter-Replace with new filter.

Carburetor Air Cleaner-Paper ElementType-

EO Clean or replace. Oil Bath Type-Clean and

refill with SAE 30 Engine Oil.

EO

Engine Oil-Drain and refill. See viscosity chart CC Carburetor Choke Shaft and Linkage-Apply

solvent to choke shaft ends through air horn.

MultiOrades

S

Manifold Heat Control Valve-Treat shaft with

SAE 2OW-40 Where temperatures are consistently solvent.

above 32'F. Crankcase Ventilatlon System-Test system and

SAE 1OW-30 Suitablefor year long operation in many service, as required.

parts of the

US.;

may be used where Engine

Oil

Filter-Replace with new fllter.

temperatures occasionally drop as low AA Automatic Transmission-Check level with

engine idling in neutral and thoroughly warm.

as -1OOF.

DCL Distributor Cam and Rubbing Block-Apply to

Recommended where minimum tempera- cam and rubbing block.

tures consistently are below +1

O'F.

Single Grades EO Distributor Oil Cup and Cam Wlck under

SAE 5W-20

SAE

30 Where temperatures consistently are Rotor block.

SAE 1OW Where temperatures range between

G

Front Brake Assemblies and Wheel Bearlngs

Body Mechanism-See Body Maintenance

HL

Manual Steering Gear-Check level. Add lubri- Section

or cant,

if

necessary.

MP

MML

Column-Mounted ManualTransmissionGear-

shift Controls-Apply

film

of lubricant to con-

tact surfaces.

above 32'F. Engine Tune-up

+32OF. and -1 0°F.

MML

Column-Mounted Automatic Transmlsslenl

/

/I

2

or

Controls-If boot

is

damaged, replace and

AMGrelubricate mechanism.

necessary.

damage. Replace

if

necessary.

MML

Front Suspension BallJoints-Inspect seals for

HTF Brake Master Cylinder-Check level.

Fill

if

I//

l,T/$'f

7

MML

Steering Linkage Boll Joints-Inspect seals for

MML

or

Clutch Torque Shaft.

AMO

MML

Clutch Drive Lugs, Release Bearing Sleeve,

or

Fork Fingers and Pivot.

AMG

EO Floor Mounted Manual Transmission

Gear-

shMt Mechanism-Lubricate mechanism from

under car with light with SAE 30

Floor Mounted Automatic Transmission Con-

holr-Lubricate with SAE

30

after removing

console toD trim aanel.

damage, replace

if

damaged or worn.

EO

AA ManualTransmlrsion-Check level, maintain to

filler hole.

UJ

HL

or

Universal Joints-Inspect seals for leokage.

/

Inspect joints parts for wear.

Rear Axle and SureQrip-Check level. Main-

tain level to flller hole.

I\

ll

/

Positionfor liftadapter

MI

#See

Crankcase Ventilation System Servicing.

I

A

Prepackedbearing

0

Coolingsystem drain

TIRE

PRESSURES (PSI) (COLD)

Size Front Rear

1

7.00~13AV-2 exceDt Sta. woo. 24 22

1

7.00~13AV-2 Station Wagon

-

7.00~13AV-2 Barracuda

7.75~14AR-2 Station Wagon

7.75~14ARO-2 except Station

7.35~14AR-2

Wagon

775x14 AP-2

8.25~14AP-2 with

"B"

engine

8.55~14AP-2 and/or air condition-

ing Stotion Wagons

22 24%

24 24

24 22

24 26%

24 22

24 22

24 22

22 26*

*Increase rear tire pressure

6

psi on loaded

Station Waaons.

PLYMOUTH

I

V=8

NK574

Fig. 2-lubrication System

(V-8

Models)

Deck Lid Hinges

Door Hinges

Door Striker Plates

Door Striker Rotor

Fuel Tank Filler Door

Hood Hinges

Tailaate Torsion Bar and Check Arm Guide Plate

Throile Linkage

KEY TO LUBRICANTS

AA Automatic Transmission

AMG Automotive Multi-Purpose

Ormse

CC Carburetor Cleaner

DCL Corn Lubricant 1473595

EO Engine Oil

HTF High Temperoture Brake Fluid 2421352

HL

Hypold Lubricant 1879414

ML

Lubtipiate 1064768

MML

Multi-Mileage lubricant 2525035

MP Multi-Purpose

Gear

Lubricant

PSF Power Steering Fluid 2084329

S

Manifold

Heat

Control Valve

Solvent 1879318

SL

Stoiniess Stick Lubrlcant 1064769

UJ Universal Joint

Grease

Fluid, AQ-ATF, Suffix "A" 1843314

CAPACITIES

Engine Oil.

..............................

.4qts.

Cooling AV-2 Models..

..................

.17 qtr.

system AR-2 AP-2 Models..

.............

.2O qts

Reor AxleAV-2 Models.

....................

.2 pt%

AR-2 AP-2 Models.

...............

.4 ph.

AV-2 Models..

................

.I7

pth

AR-2, AP-2

model^.

..........

.19.5 pts.

AV-2, AR-2, AP-2 Models.

....

.4.5 ptS

AV-2 Models..

...............

.7

pts

AR-2, AP-2 Models.

.........

.7.5 pts

Fuel Tank AV-2 Models..

.................

.18

gals,

Wagons..

..................

.19

gob,

AR-2 Stotion Wagons..

..........

.21

gals,

(Add 1 qt. when replacing fllter)

AR-2 (361,383 and 426 cu.in. engines)l6 qts.

(Add

1

qt. for heater)

Transmission

TorqueFlite

Manual 3-Speed

4-Speed

AR-2 Models except Station

AP-2 Models

except Station Wogons.

.......

.25 gals.

AP-2 Station Wagons.

...........

.22 gath