SECTIONI

FRONTSUSPENSIONSYSTEM

Page

DataandSpecifications8

1.

FrontWheelAlignment7

2.

FactorsofFrontWheelAlignment7

3.FrontWheelAlignmentCorrections10

4.TieRodEnds12

5.SteeringKnuckleandSupport12

6.UpperControlArm14

7.UpperControlArmPin,BushingandDustSeal14

8.LowerControlArmandFrontSpring14

9.

FrontShockAbsorber15

10.

DiagnosisProcedures16

1.

FRONTWHEELALIGNMENT

Theneedforcheckingthealignmentofthefront

wheelsisusuallyindicatedbythewaythecar

steers,suchasa tendencyforthecartoleadto

oneside,ortowander.Certaintypesoftirewear,

suchastoe-inortoe-outwear,orcamberwear,

indicatetheneedforcheckingsomeofthefactors

ofwheelalignment.

Ifitisconsiderednecessarytocheckthewheel

alignmentofa newcar,itshouldberemembered

thatthefrontwheel suspensionpartsareclosely

fittedandtheirmovementis

stiff.

Asa result,a

newcarwillnotalwayssettletothepositionwhere

correctreadingscanbeobtained.Whenservicing

anewcar,itisbesttocheckonlythetoe-inofthe

frontwheels.Afterthecarhasbeendrivenabout

3,000miles,thestiffnessofnewpartswillbere-

lieved,andifwheelalignmentcorrectionsare

necessary,theycanbemadeatthenormalriding

level.

IMPORTANT

Frontwheel alignment equipment should be

checked frequently with the proper checking

equipment. Equipmentthat has

been

damaged

by dropping or rough handling should be care-

fully checked and adjusted before it is

used.

The floor must be level when using portable

equipment.

2.

FACTORSOFFRONTWHEEL

ALIGNMENT

Thefactorsoffrontwheelalignmentaregener-

allyconsideredtobecamberandkingpininclina-

tion,

caster,toe-inofthefrontwheelsinthe

straight-aheadposition,andtoe-outofthefront

wheelsonturns.

Inadditiontothesefactors,thereareothercon-

ditionsthataffectsteeringcontrol.Theseare:im-

propertirepressure;wheelwobble;unbalanced

wheel andtireassemblies;saggedorbrokenfront

orrearsprings;damagedsteeringgearparts;

draggingbrakesorbentframe.

Frontwheelalignmentsettingsmustbeheldto

specificationswithinreasonablelimitsinorder

thatthevehiclemayexhibititsbeststeeringchar-

acteristicsandinordertoholdtherateandun-

evennessoftiretreadweartoa minimum.

Wheelalignmentmeasurementsshouldbetaken

withrecommendedtirepressureswithnopassen-

gerload,andwithcarstandinginitsnormallevel

positionwithnojacksunderit.Camber,casterand

toemeasurementsmustbemadewiththefront

wheelsonfloatingturn-tables.

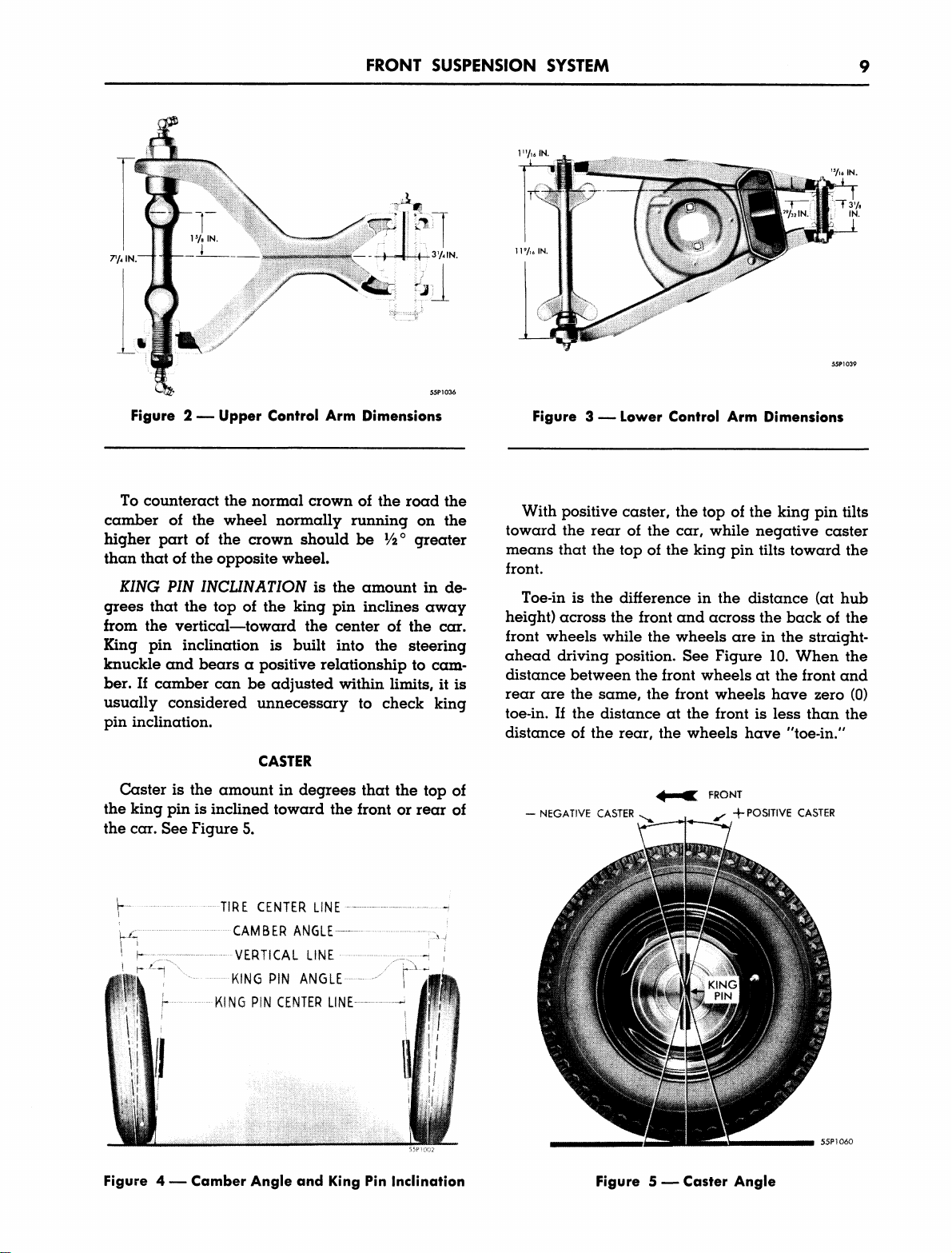

CAMBERANDKINGPININCLINATION

CAMBER

istheamountindegreesthatthefront

wheelsinclinefromtheverticalwhenviewedfrom

thefrontofthecar.Seefigure4.Wheelswithposi-

tivecamberarefartherapartatthetopthanatthe

bottom.Wheelswithnegativecamberarefarther

apartatthebottomthanatthetop.

MyMopar.com