010219/0 ControlPro/Diluter EN - 3

PREFACE

Using this manual

This manual is intended to be used as a work of reference for

professional, well trained and authorised users to be able to

safely install, use, maintain and repair the product mentioned

on the cover of this document.

Pictograms and symbols

The following pictograms and symbols are used in this manual:

TIP

Suggestions and recommendations to simplify

carrying out tasks and actions.

ATTENTION

A remark with additional information for the user. A

remark brings possible problems to the user’s

attention.

CAUTION

Procedures, if not carried out with the necessary

caution, could damage the product, the workshop or

the environment.

WARNING

Procedures which, if not carried out with the

necessary caution, may damage the product or

cause serious personal injury.

CAUTION

Denotes risk of electric shock.

Text indicators

Listings indicated by “-” (hyphen) concern enumerations.

Listings indicated by “•” (bullet point) describe steps to

perform.

Product indications / Abbreviations

Product type: Equals to:

- ControlPro/Panel Panel

- ControlPro/HMI HMI1

- SCS-Diluter PRO SCS-Diluter

1 INTRODUCTION

1.1 Identication of the product

following data:

- product name

- serial number

- supply voltage and frequency

- power consumption

1.2 General description

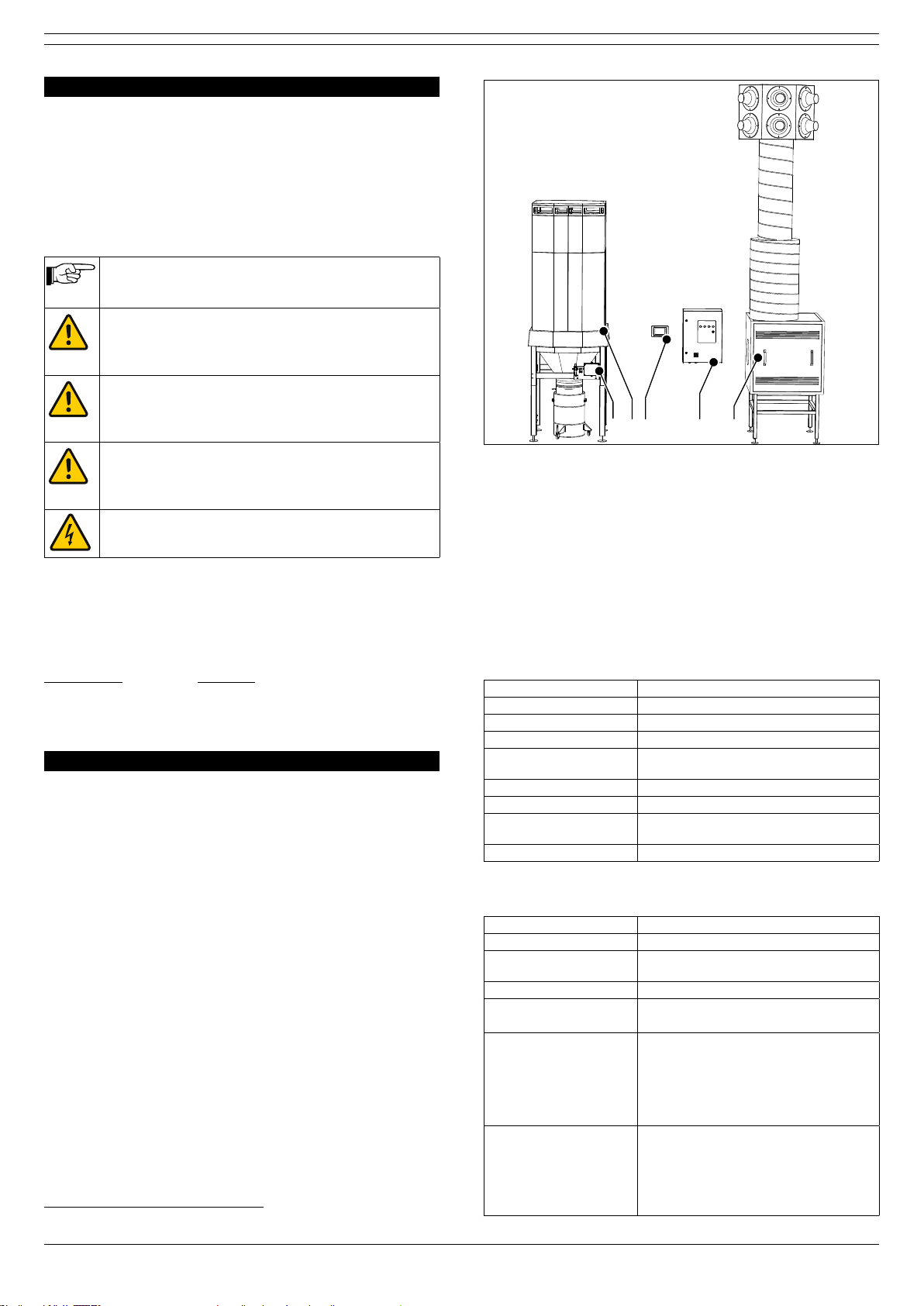

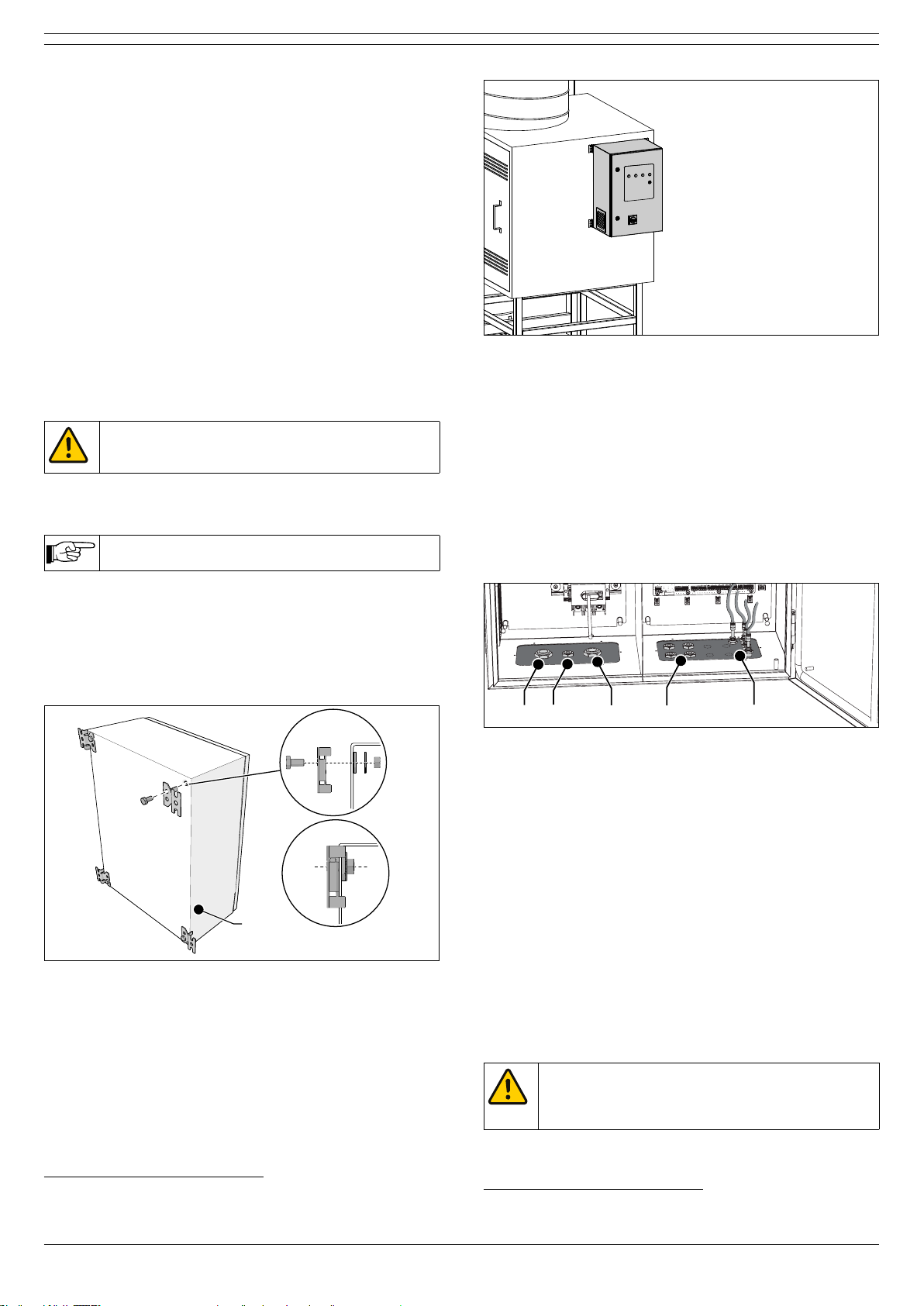

ControlPro/Diluter of Plymovent is an intelligent control panel

with an integrated frequency inverter and a separate HMI, that

is supplied including the required connection cables. This

system controls the fan and the compressed air valves of the

The control panel contains a frequency inverter and is divided

in two compartments (high voltage and low voltage).

Fig. 1.2

A Junction box CB-SCS

B Filter system SCS-Diluter

C HMI

D Panel [control panel]

E Extraction fan

1. Human Machine Interface

Fig. 1.2

B C D EA

SCS-Diluter + ControlPro/Diluter

1.3 Options and accessories

The following products can be obtained as an option and/or

accessory:

- Panel HMI cable 30 or 60 m (98 or 197 ft), instead of

standard length 15 m (49 ft)

- LightTower

- external pressure sensors (PT-1000 or PT-2500)

1.4 Technical specications

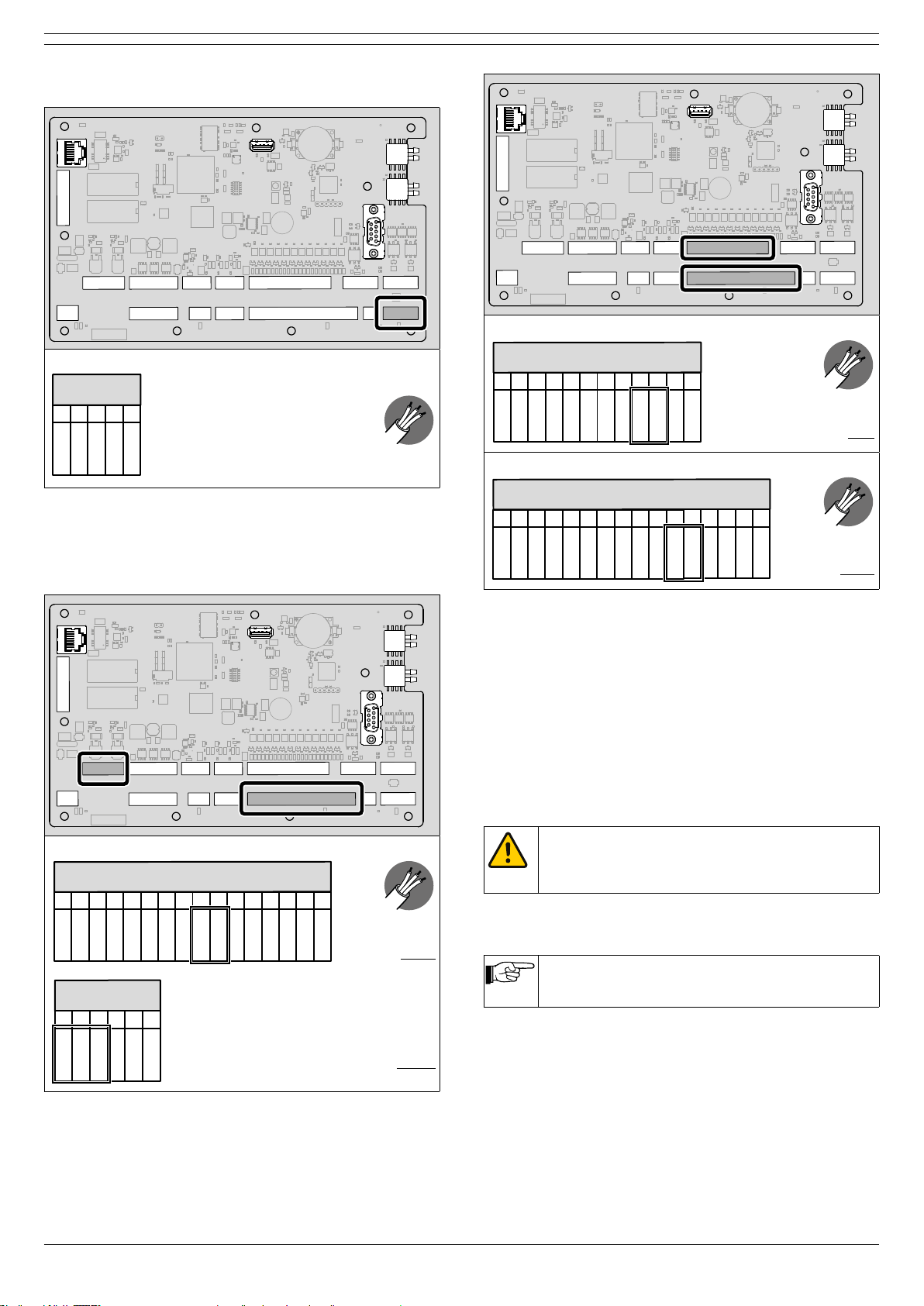

1.4.1 ControlPro/Panel

Dimensions refer to Fig. I on page 36

Weight 55 kg (121 lbs)

Material of housing sheet metal

Protection class IP 54

Input voltage 400V3ph/50Hz | 480V/3ph/60Hz |

600V/3ph/60Hz

Internal operating voltage 24 VDC (controls) | 115V / 230V (cooling fan)

Power consumption max. 7,5 kW

Internal pressure sensors

pressure and fan pressure)

400V: CE | 480V / 600V: cULus (UL 508A)

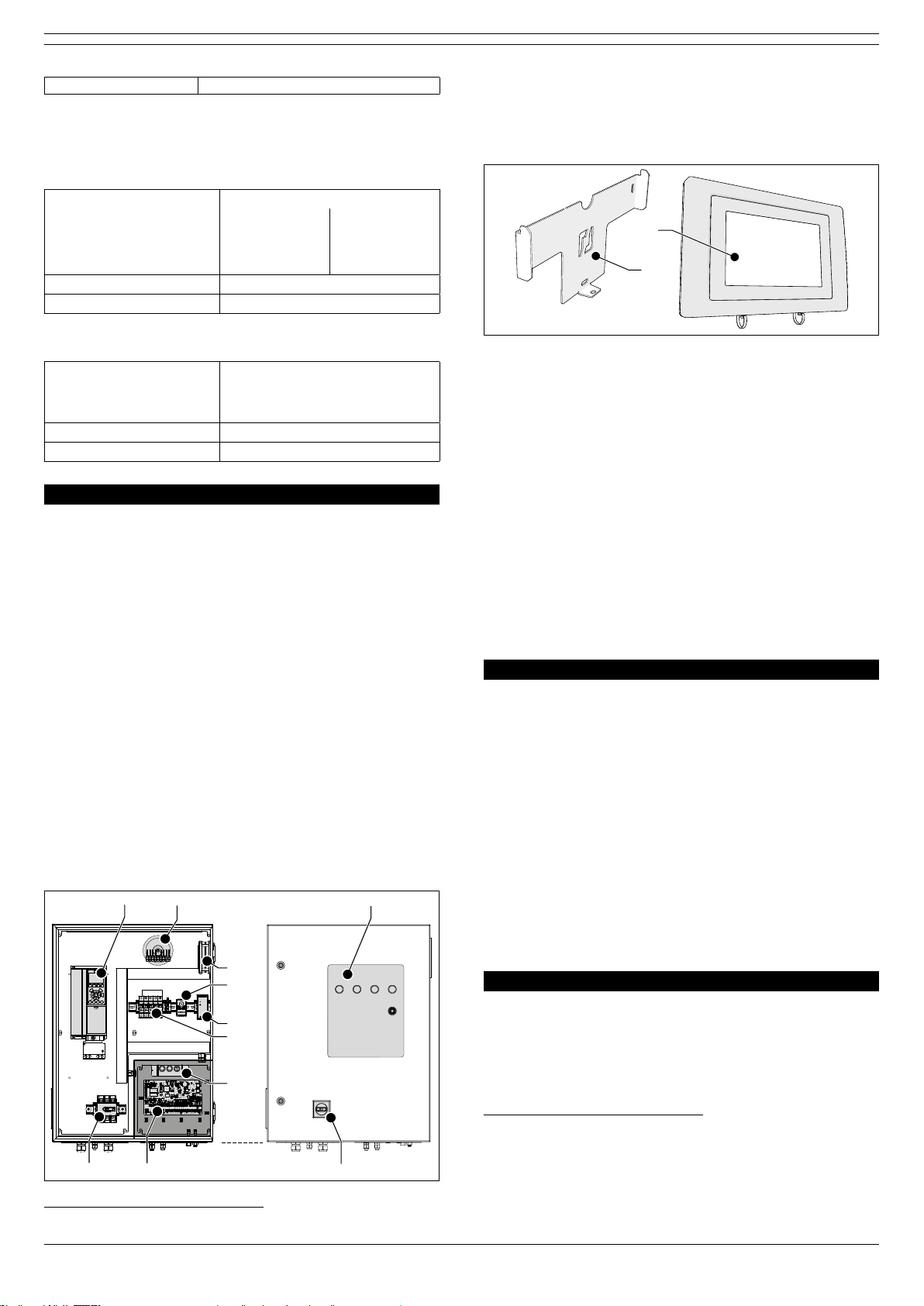

1.4.2 ControlPro/HMI

Dimensions 255 x 165 x 125 mm (10.0 x 6.5 x 4.9 in.)

Weight 900 g (2 lbs.)

Material of housing

-

PC/ABS

- UL94 V-0

Operating voltage 24 VDC (+/- 15%)

Power consumption -

- display on: max. 5 W

External connectors - CAN + power (connection to Panel)

[M12-5p shielded connector]

- USB 2.0 (host only)

[USB A receptacle, with dust cap]

- ethernet 10/100 Mbit/s

[RJ45, shielded, with dust cap]

Display:

- size

- type

- brightness

- colour

- resolution

- 7”

- resistive touch screen

- 300 cd/m²

- 262K

- 800 x 480 pixels