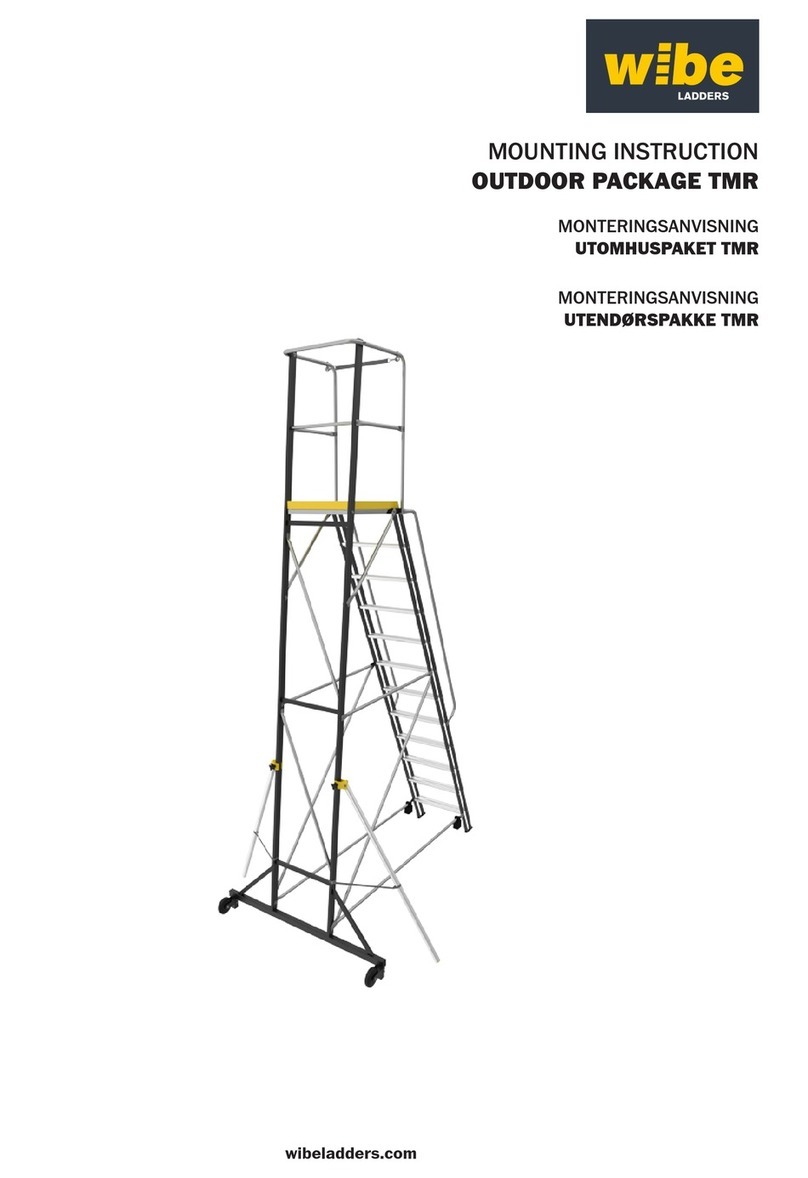

MOVING TOWER

Before

-The tower should only be moved by manual eort, and only from the base.

-When moving the tower, beware of live electrical apparatus, particularly overhead, plus wires or moving

parts of machinery.

-No personnel or materials should be on the tower during movement.

-Make sure all castor wheels’ brakes are in release position.

-Caution should be exercised when wheeling a tower over rough, uneven or sloping ground, taking care

to unlock and lock castors. If stabilizers are tted, they should only be lifted suciently above the ground

to clear ground obstructions. The height of the tower, when being moved should not exceed 2.5 times the

minimum base dimensions, or 6 meters overall height.

After

-Relock castor and ensure that the tower is both vertically and horizontal aligned.

-Reposition stabilizers and ensure they have safe footing.

-Where necessary re-tie the towers to a rigid structure.

-Do not suspend mobile access towers without referring to your supplier.

-Atower must be kept in good working order. Any parts found to be faulty or missing should be

immediately replaced.

CARE & MAINTENANCE

-Equipment should kept clean, especially joints and moving parts.

-All working parts e.g. joints, threat should be lubricated lightly with oil.

-Do not let parts fall to the ground. Such abuse may reduce the structure integrity and

load capacity of the equipment.

-In the event of damage, the defective equipment must only be repaired by the qualied

personnel approved by the manufacturer

CHECK LIST

1. Inspect components before erecting the tower.

2. Ensure that the tower is upright.

3. Ensure all castors are locked.

4. Ensure all castors are rmly sited on the ground, not in hanging position

5. Ensure base plates are rmly sited on the ground. Sole plate needed when the tower is used on soft soil.

6. Ensure the tower is levelled by adjusting the adjustable leg.

7. Ensure Stabilizer are tted as specied in the assembly guide.

8. Ensure all the braces & platforms are properly installed.

9. Ensure the Handrails are tted in place.

10. Ensure Toe boards are correctly tted as specied in the assembly guide.

11. Ensure the Easy Access handrails are properly installed.*

12. Ensure the Couplers are locked rmly at the correct location.*

13. Ensure the Ballast is correctly in place.*

aa

a

aWALL

WALL

To position the tower in free

standing. Adjust the stabilizer

to form a square shape.

To position the tower against a

wall. Do not remove the

stabilizer, move parallel with

the wall.

To position the tower in a

corner. Remove the inside

stabilizer and place the

outside two parallel with the

wall.

STABILIZER BAR

Remarks: “*” - Applicable when item is used in the tower.

3

ASSEMBLY PROCESS

LOCK

UNLOCK

UNLOCK

LOCK