AIR REGULATOR INSTRUCTION SHEET

SAR4000 SERIES

Standard Units: Relieving

Maximum Supply Pressure: 250 PSI

Maximum Operating Pressure: 150 PSI

Operating Temperature Range: 40⁰F to 140⁰F

Installation

User must verify that the regulator is rated for the system operating pressure and has

the proper connections and accessories for the type of gas and pressures required for

their application.

Inspect the regulator for evidence of contamination or damage. Regulators with any

signs of contamination or damage should not be used.

When installing the regulator to the airline, reference the arrow on the front and back

of the regulator for air flow direction.

Use a filter to remove dirt and supply clean air to your application. Filter must be

installed ahead of the regulator. If an airline lubricator is used, it MUST be located

downstream of the regulator to avoid any interference with regulator.

Note: Do not apply excess torque when installing the regulator and/or gauge. We recommend

use of liquid Teflon over Teflon tape.

Operation & Adjustments

Before supplying the air, turn the adjusting knob counter-clockwise until

compression is released from the control spring. Turn on the air supply and adjust

the knob to set the desired secondary pressure by turning the knob clockwise.

Note: Adjustment knob must be pulled away from the body of the regulator to operate. After

desired secondary pressure is set, pushing the knob back towards the body will lock the

control knob.

Warning

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS

AND/OR SYSTEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE

To avoid unpredictable system behavior that cause personal injury and property damage,

User must be trained and equipped for the handling, use and servicing of high

pressure fluids and systems.

Follow all applicable safety and maintenance procedures.

Obey local, government and agency codes and regulations.

Disconnect electrical supply if necessary before installation, servicing or conversion.

Disconnect air supply and depressurize all air lines connected to this product before

installation, servicing or conversion.

Operate within the manufacturer’s specified pressure, temperature and other

conditions listed in these instructions.

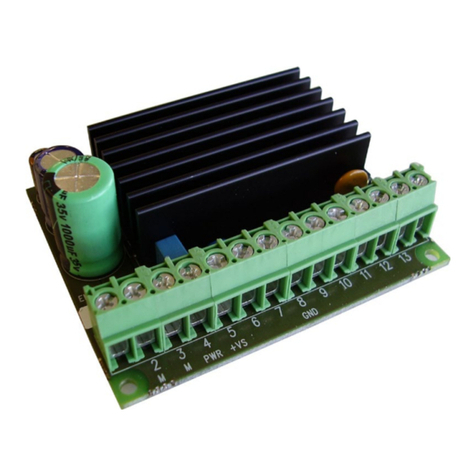

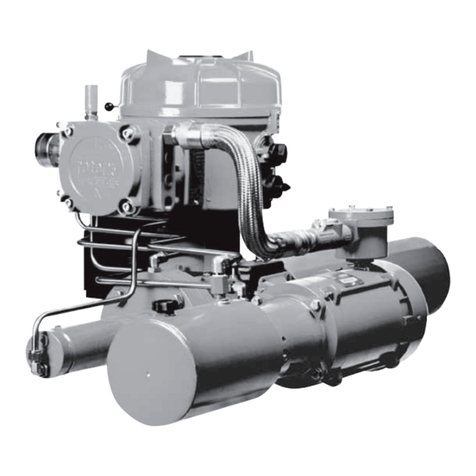

STRUCTURE/PART

MAINTENANCE

:On detection of air leaks,

pressure fluctuation, or “creep”,

depressurize system and

remove bottom cap. Inspect

valve seat for damage or wear.

Inspect seat in head casting

for foreign material or damage.

Clean with kerosene and blow

out with air. Replace

any damaged parts. If leaks

persist, remove bonnet, inspect

diaphragm and diaphragm

seat for wear or foreign

materials.