Instruction manual ILC SMART PRO

3

Contents:

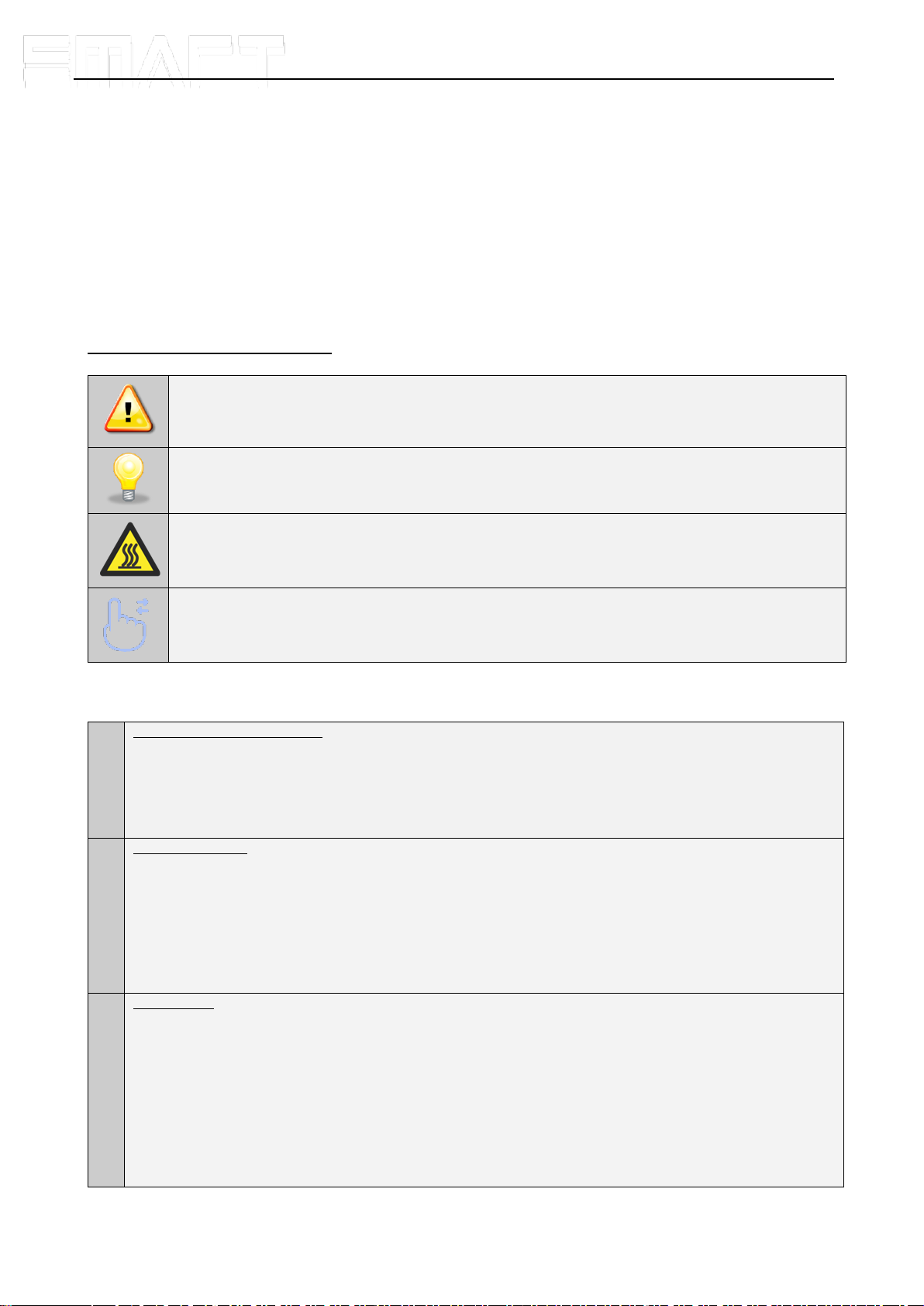

1. SAFETY INFORMATION................................................................................................................................6

1.1. Avoiding electrical shock ........................................................................................................................7

1.2. General safety instructions on installing and operating the CO2incubator .............................................7

1.2.1. Indications for using pressure cylinders .............................................................................................7

1.2.2. Characteristics of carbon dioxide .......................................................................................................8

1.2.3. Location requirements........................................................................................................................8

1.2.4. Hazards when working with CO2........................................................................................................8

1.2.5. Presonal protection / first aid..............................................................................................................8

1.2.6. User’s responsibility ...........................................................................................................................9

2. PACKAGE CONTENTS..................................................................................................................................9

3. BEFORE THE FIRST USE............................................................................................................................10

3.1. Setting up the chamber.........................................................................................................................11

3.2. Shelf / water pan installation.................................................................................................................12

3.3. Water pan.............................................................................................................................................13

3.4. Remarks on the placement of samples.................................................................................................14

3.5. Closing chamber door...........................................................................................................................14

3.6. Internal glass door................................................................................................................................14

3.7. Connection of the CO2gas cylinder......................................................................................................15

4. DESCRIPTION OF THE unit ........................................................................................................................16

4.1. Design of ILC incubators ......................................................................................................................16

5. UNIT EQUIPMENT........................................................................................................................................17

5.1. Internal glass door................................................................................................................................17

5.2. Door lock ..............................................................................................................................................17

5.3. Access ports for external sensor...........................................................................................................18

5.4. Open door alarm...................................................................................................................................18

5.5. USB port...............................................................................................................................................18

5.6. LAN port ...............................................................................................................................................19

6. DEVICE OPERATION...................................................................................................................................19

6.1. External memory (USB flash drive).......................................................................................................19

6.2. First boot...............................................................................................................................................20

6.3. Using the keypad..................................................................................................................................20

6.4. User logging in......................................................................................................................................21

6.5. Main screen.................................................................................................................................21

6.5.1. Information panel..............................................................................................................................23

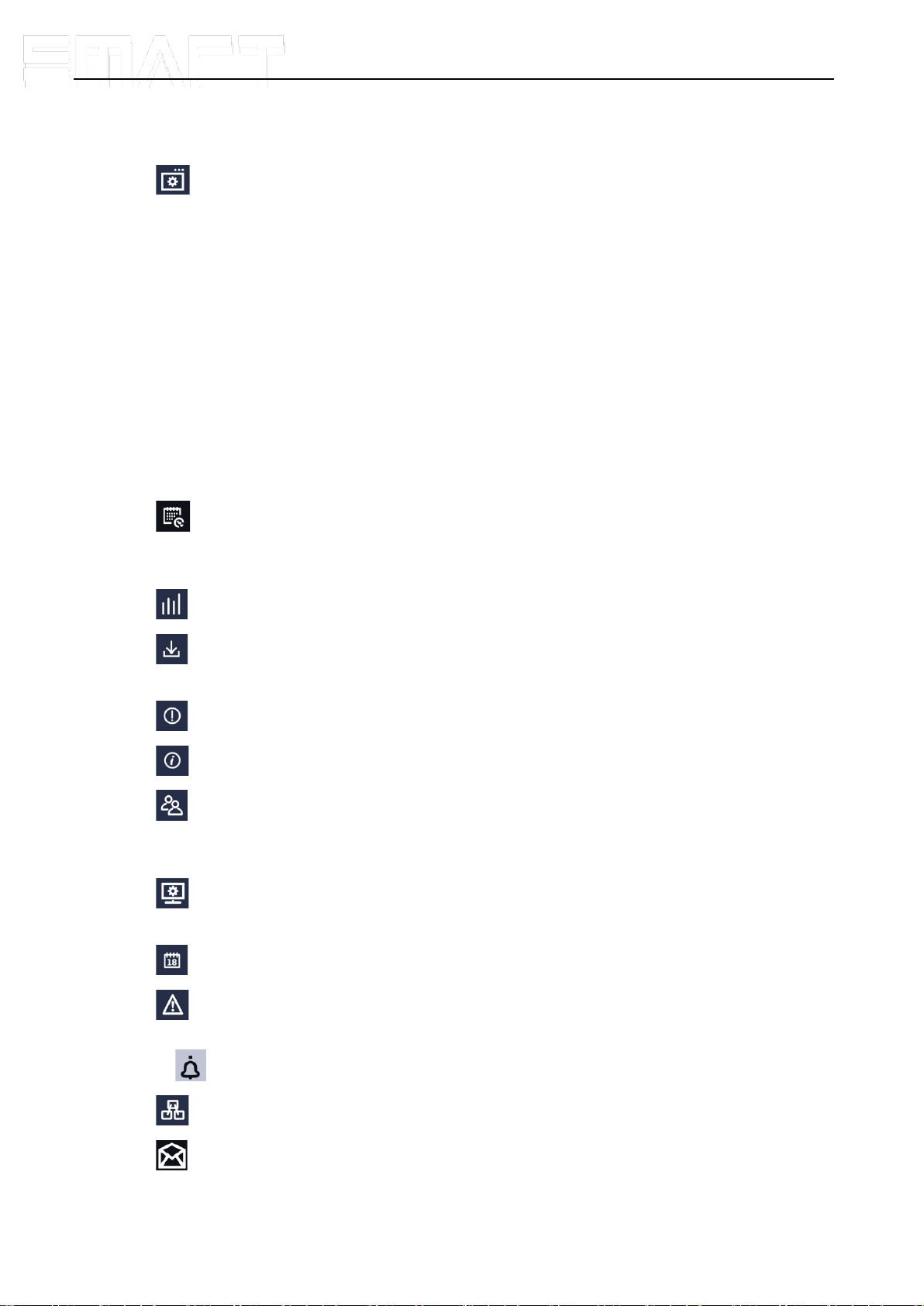

6.5.2. The meaning of icons and symbols..................................................................................................25

6.5.3. Upper expandable and configurable menu.......................................................................................27

6.5.4. Quick Note –user’s message...........................................................................................................29