2

Index

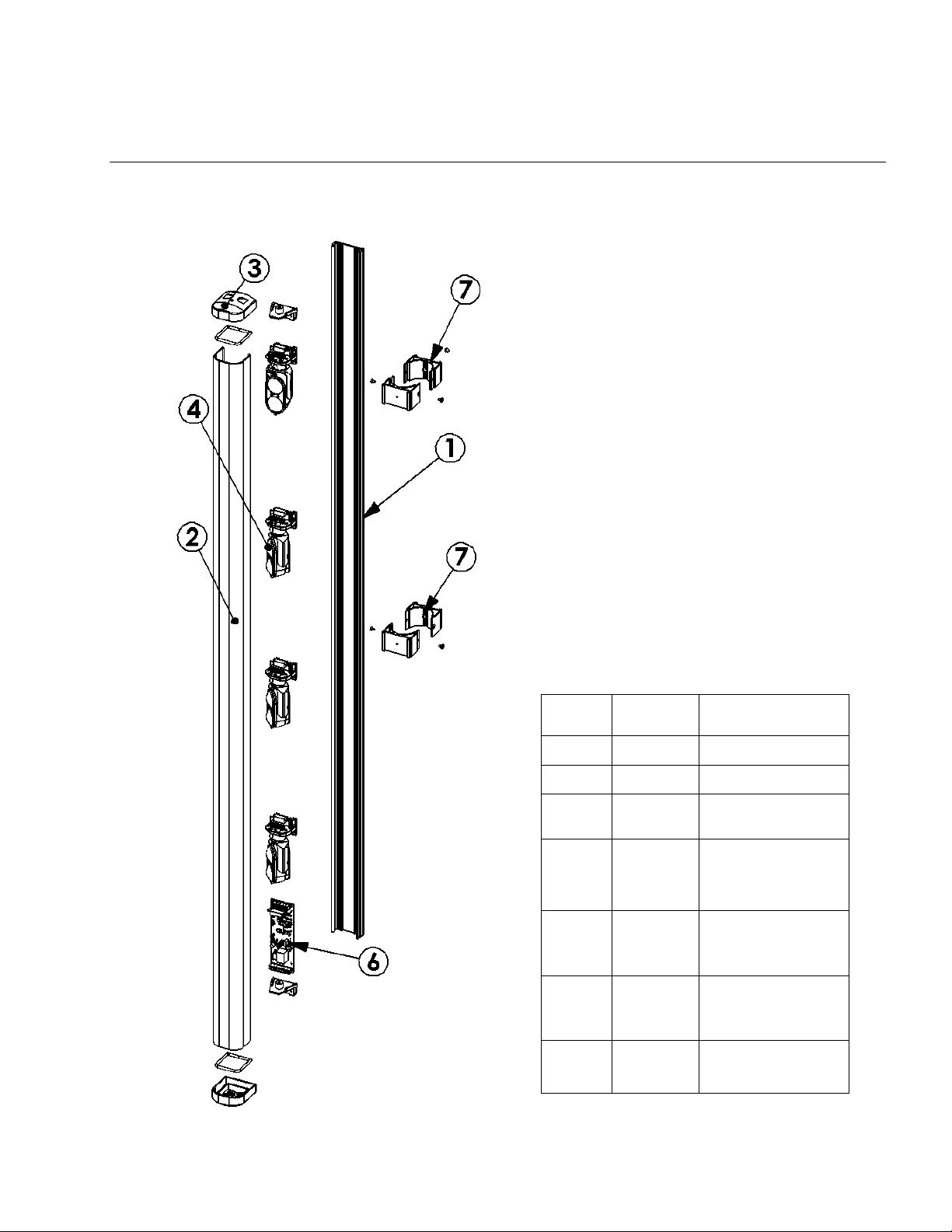

Main components list Pag. 3

Installation reccomendations Pag. 4

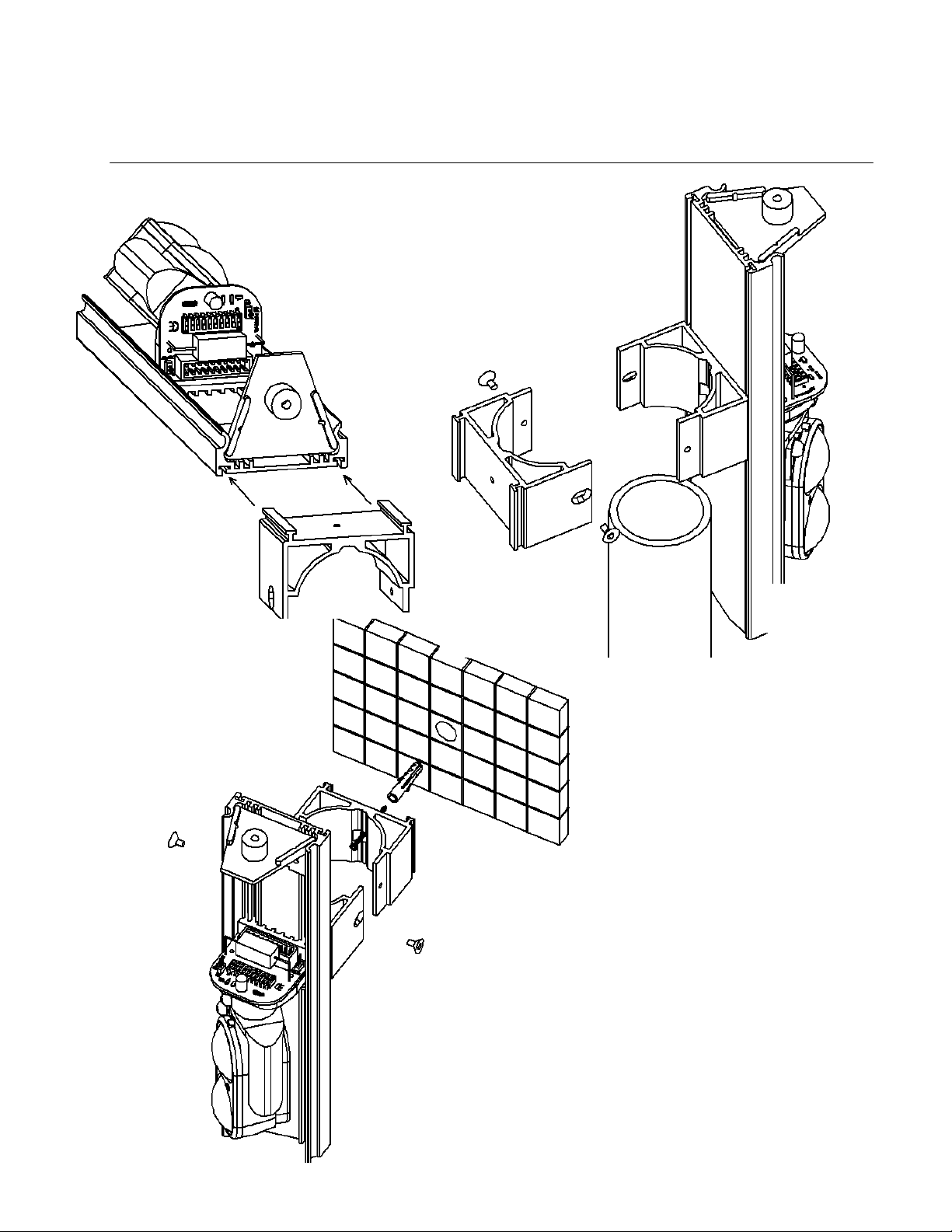

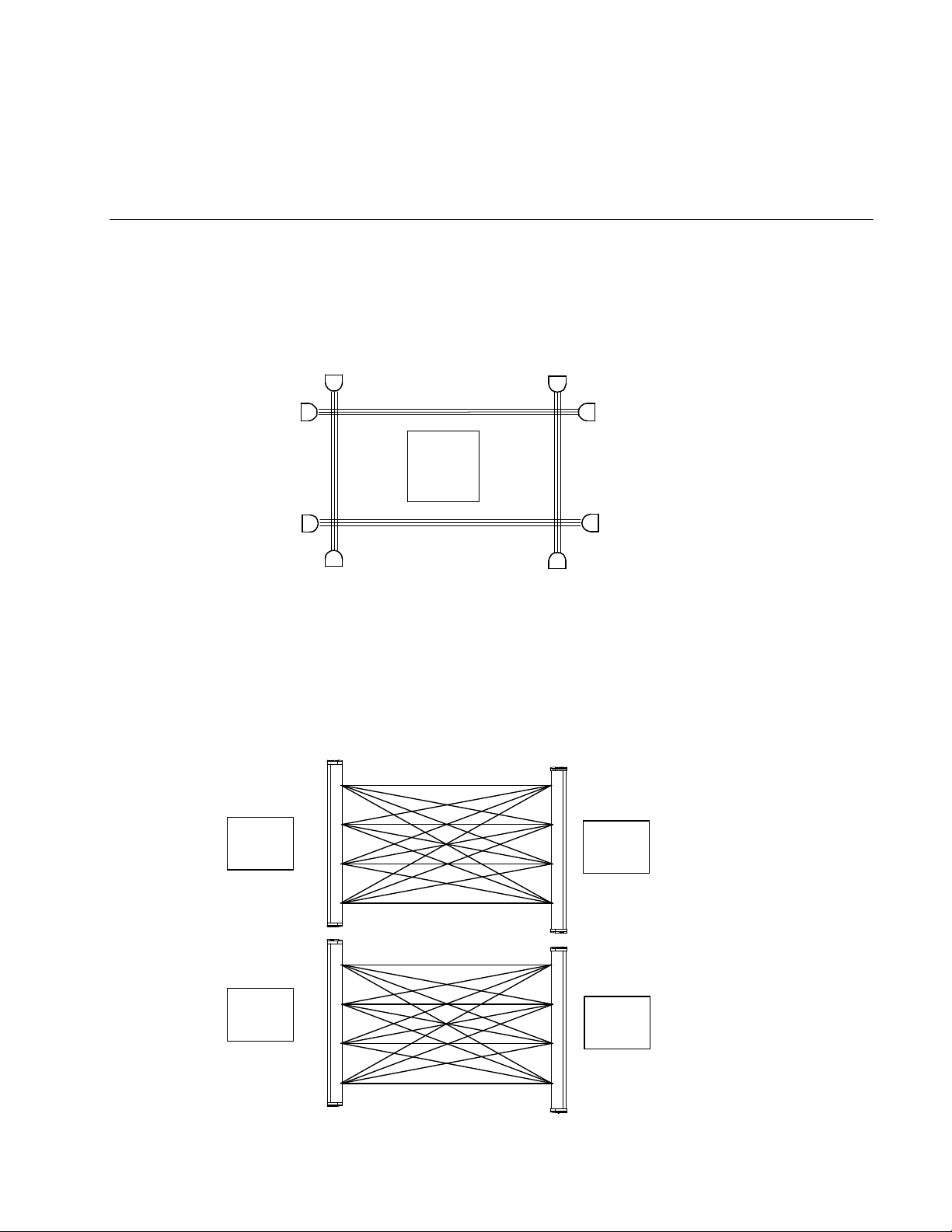

Mounting the bracket Pag. 5

Installation example Pag. 6

Positioning the beam with respect to others in the perimeter Pag. 7

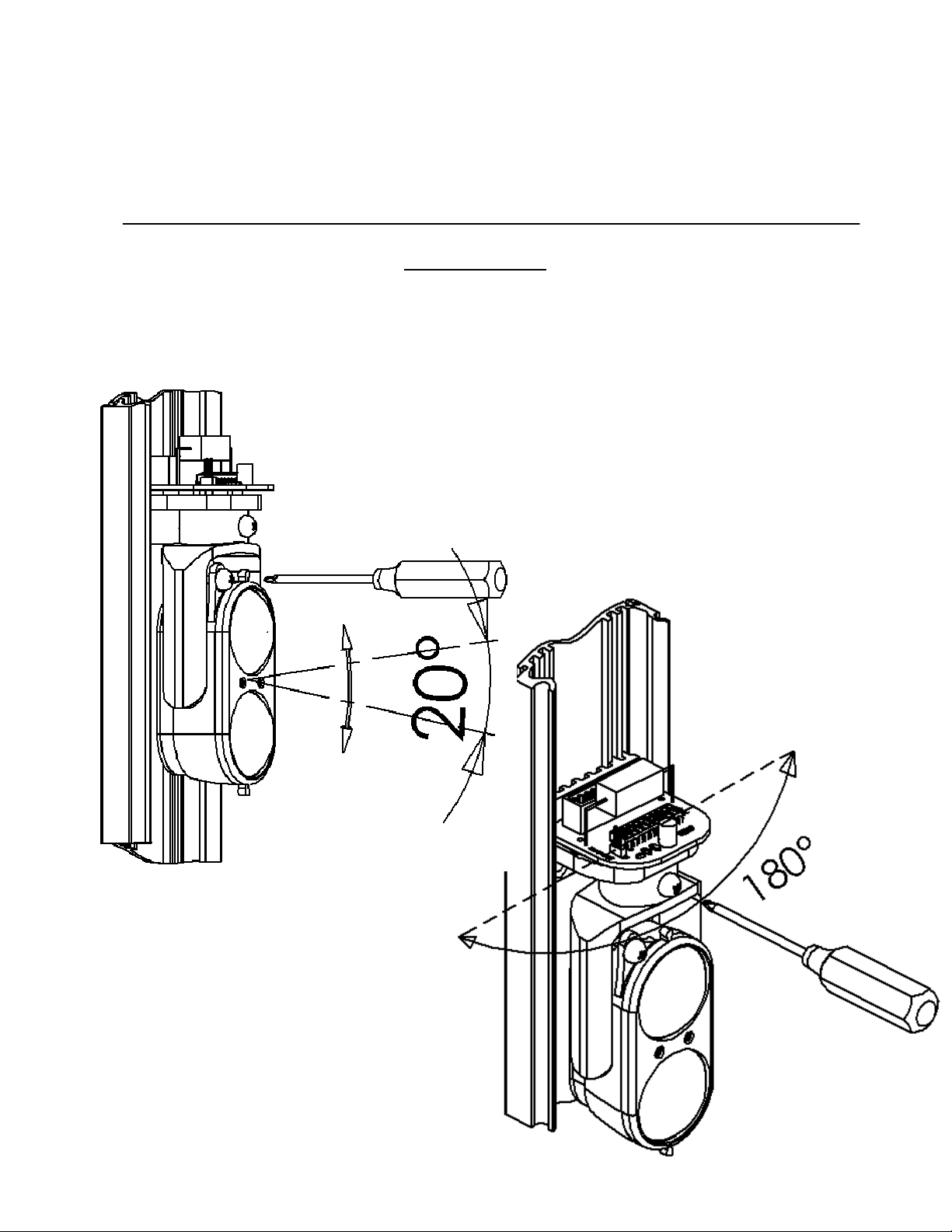

Alignment Pag. 8

Vertical alignment of the mirror Pag. 8

Horizontal alignment of the mirror Pag. 8

Cabling and terminal connections Pag. 9

Transmitters main P.C.B. Pag. 9

Receivers main P.C.B. Pag. 10

Set-up using the test point on the main Transmitter P.C.B. Pag. 11

Set-up using the test point on the main receiver P.C.B. Pag. 14

Set up examples Pag. 15

Alignment checking Pag. 16

Setting and programming Pag. 17

Functional description of the led’s Pag. 17

Operational characteristics and Link setting Pag. 18

Technical specifications Pag. 19