1. PVT005 Lid (Solution Tank)

2. PVT001 Solution Tank

3. PVT001A Recovery Tank

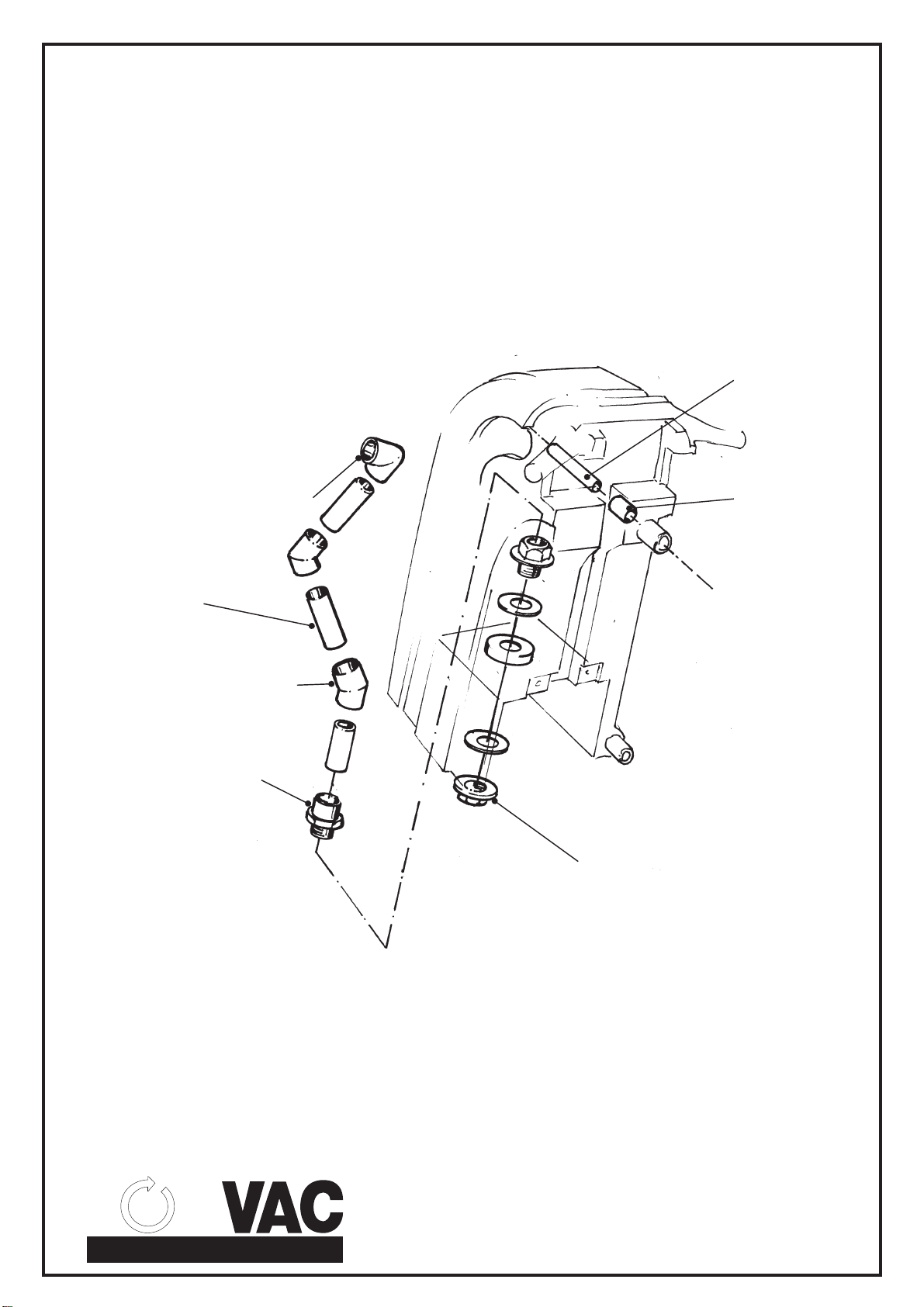

4 PVT035 Elbow Fitting

5 PVS060 Hose Quick Clamp

6 PVS067 Solution Hose

7 PVS013 Solution Valve Assembly

8 AAA537 6mm x 12mm Set Screw

9 AAD039 Bolt

10 VPA284 Nut

12 AAD038 1/4 x 1½

14 COM019 Rubber Seal

15 PVT100D Bottom Plate (Vac Cover)

16 PVT033 Spring

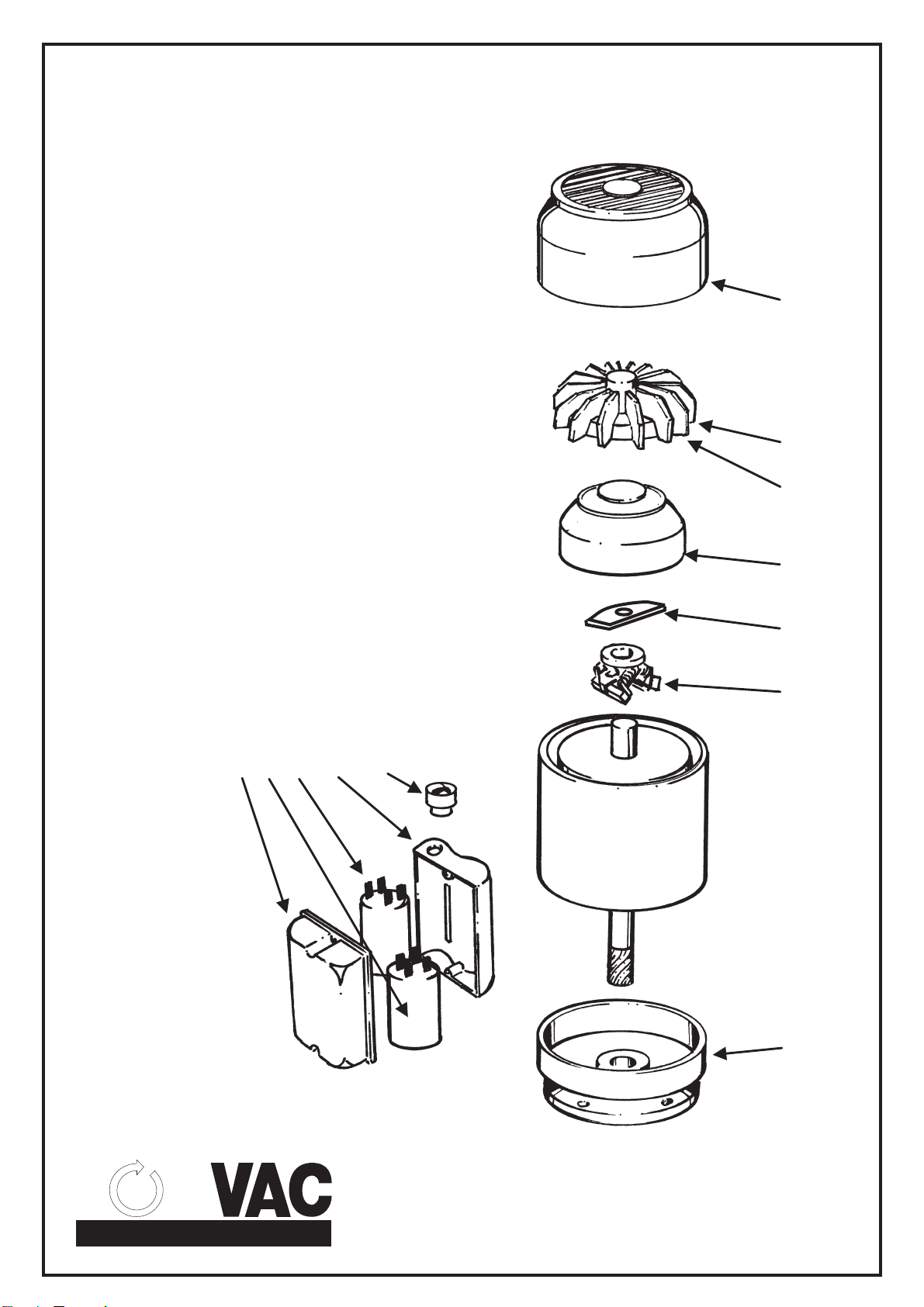

17 PVT002 Vac Motor

18 COM086 Seal (Motor Support)

19 VPA906 Spring Tensioner Trigger

20 AAA501 3/16 x 1 / Screw C/S

21 VPA838 Trigger

22 PVT100J Exhaust Cover

23 PVT100A Handle Stem

24 VPA231 Tongue Assembly

25 AAF140 1/4 Nylon Nut

26 VPA767 Fork

27 VPA284 Handle Pin & Nut

28 SLB038 3/16 Nylon Nut

29 AAG236 Flat Washer

30 PVT086 Support Bracket (Handle)

31 AAA604 Bolt (H/T 1/4 x 1) S/S

32 PVT027 Flat Washer

33 SLB038 3/16 Nylon Nut

34 PVS077 Water Release Hose

35 PVT047 Plug PVT048 Sleeve

36 VPV156 Ring

37 PVS974 Terminal Block (5 Term)

38 PVS041 Wiring Box

39 PVS096 Gland

40 AAM601 Terminal Block

41. PVT200 Hose Clamp

42 388019 Micro Switch (Activate Drive Motor)

43 VPA622 Half Clamp

44 AAJ002 Star Washer

45 AAA354 3mm Nut

46 388019 Micro Switch (Activate Vac Motor)

47 PVT008 Squeegee Lift Cable

48 AAA353 3mm x 25mm Screw

49. PVT006 Lid (Recovery Tank)

50. PVT015 Rubber Seal

51 AAA354 6mm Nylon Nut

52 PVT100K Rod (Squeegee Lift Handle)

53. 364527 Knob (Squeegee Lift Handle)

54. PVT100E Squeegee Lift Handle

55. PVT100A Backing Switch Plate

56. PVT100G Switch Plate

58 PVT100E Washer (Activate Vac Motor)

59 AAG385 Washer

60 PVS095 Hose Cuff

61 PVS121 Extract Hose

62 VVA019 No. 4 Clamp

63 ZDR078 Indicator Light

65 PVT100F Cover Plate

66 387670 Knob (Detergent Lift Handle)

67 PVT017 Rod Solution

68 PVT028 3/16 x 5/8 Self Tap

69 VPV120 Clip (Hose Retainer)

70a VVA019 Cable Clamp No.4

70b BV8003 Ring

71 BV8003 Strain Relief

72 AAA564 Set Screw 1/4 x ¾

73 AAG236 Flat Washer

74 VPA104 Oil Seal

75 VPA114 Bearing

76 VPA116 Shaft

77 AAA501 3/16 x 1”

78 PVS424 Casting

79 VPV239 Insert

"

80 VPV087 Buffer

81 VPA328CMG Drive Motor

81a SK006 Screw 5/16

81b VPV542 Nut 5/16

82 AAD041 Screw

83 VPA836 Rubber Grommet

84 VPA177 Base Plate

85 VPA121 Wavy Washer

86 VPA570 Bearing

87 VPA411 Gear

88 VAA113 Cover Plate

89 VPA122 Washer

90 AAA564 Set Screw 1/4 x ¾

91 PVT045 Nut 5/16

92 PVT044 Cap Head Screw 5/16

93 PVS085 Knob

94 PVS042 Gcrub Screw

95 PVT044 Cap Head Screw 5/16

96 VFB115 Woodruff Key

97 PVT090 Height Adjustment Wedment

98 PVS078 Drive Hub

99 PVS009 Height Adjustment Rod

100 387116 Pilot Hub

101 PVS087 Height Adjustment Bracket

102 PVS026 Cap/Head Screw 5/16 x 11/4

103 AAA564 Set Screw 5/8 x ¼

103a GAS041 ¼ Spring Washer

103b AAG236 Washer

104 PVS092 Shaft

105a PVS118L Left Spring

105b PVS119R Right Spring

105c PVS119L Left Spring

105d PVS118R Right Spring

106 370711 Thumb Nut

107 VPA820 Spacer (Swivel Tongue & Squeegee)

108 PVS006 Swivel Squeegee

109 PVS052 Skirt Assembly

110 VPV168 Mini Skirt (ref 109 Skirt Assy.)

111 VPV172 Retainer Skirt

112 VPV042 Pickup Ring

113 PVS40B2 Brush

114 PVT009 Turn Buckle

115 PPR095 Nut Nylon

115a PVS039 S/S Nut 3/16

116 VPA829 5/32 Roll Pin

117 PVT038 Flat Washer

118 PVT007 Wheels

119 SLB040 Flat washer

119a GAS041 Spring Washer ¼

120 AAA564 Set Screw 5/8 x ¼

121 PVS006 Swivel Squeegee Tongue

122 PVT011 Axle

Ref pg4 382350 Squeegee Assembly

123 382352 Weldment

124 105550 Channel

125 105551 Retainer

126 105533 Blade

127 393746 Weights

128 370711 Thumb Nut

129 387376 Roller Assy

130 363855 Frame Roller

131 ECG157 Lead Protector

132 PVT016 Plug & Lead

133 300187 Belt Clip

134 PVS070A Plastic Clamp

135 VPV476 Lead

136 VPA459 Brass Barb 5/16

137 PVS059 Brass Reducer Bush

138 PVS054 Washer 11/16 x 1 5/16

139 PVS013 Solution Valve Assy

140 PVS084 Solution Valve Retainer

141 PVT028 Screw

142 PVT018 Hinge

143 AAE232 Dom Nut

144 AAK044 Pop Rivet

(ref 109 Skirt Assy.)

(ref 109 Skirt Assy.)

1700E Autoscrubber PARTS LIST1700E Autoscrubber PARTS LIST

Page 5