PC1000-PC2000 INSTALLATION MANUAL

10275-8.doc

Polyamp AB, Sweden Page 4 (14)

1 Before installation

Before installation we recommend that you

read this and next section of this manual. If any

problem occurs, consult 12 Trouble shooting.

If the converter includes a fan, please notice 11

Maintenance.

On the front panel label the following is

displayed: Converter type, input voltage range,

nominal output voltage, serial number, options

and article number. The converter type name

consists of model name PC1000, PC1400 or

PC2000 followed by input code and output

voltage. Two examples:

•Type: “PC2000 110/48” has input code “110”

and nominal output voltage 48Vd.c.

•”Type: “PC1000 24/24” has input code “24”

and nominal output voltage 24Vd.c.

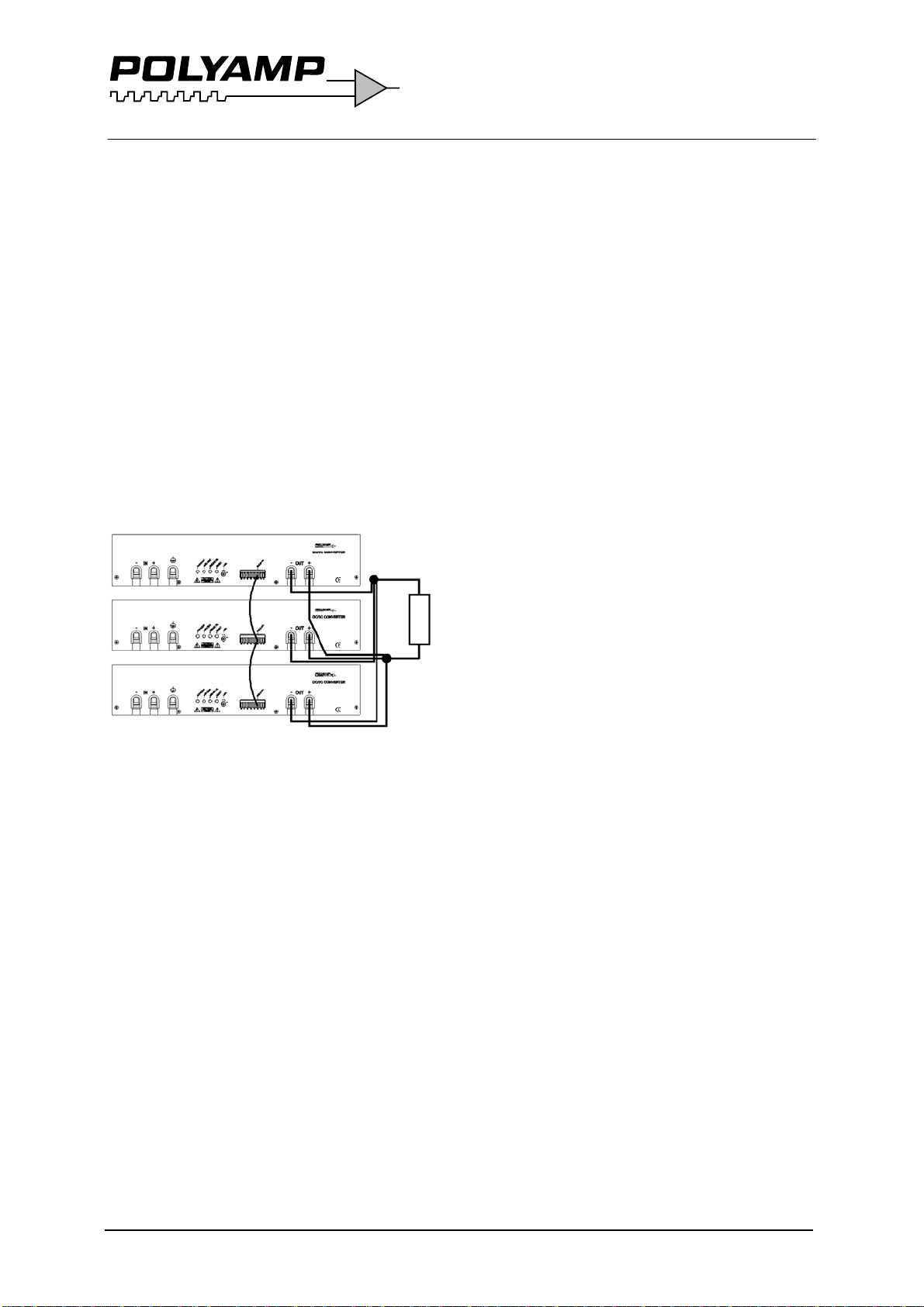

If you intend to parallel connect the output,

please check that option C is supplied. It

means series diode on output.

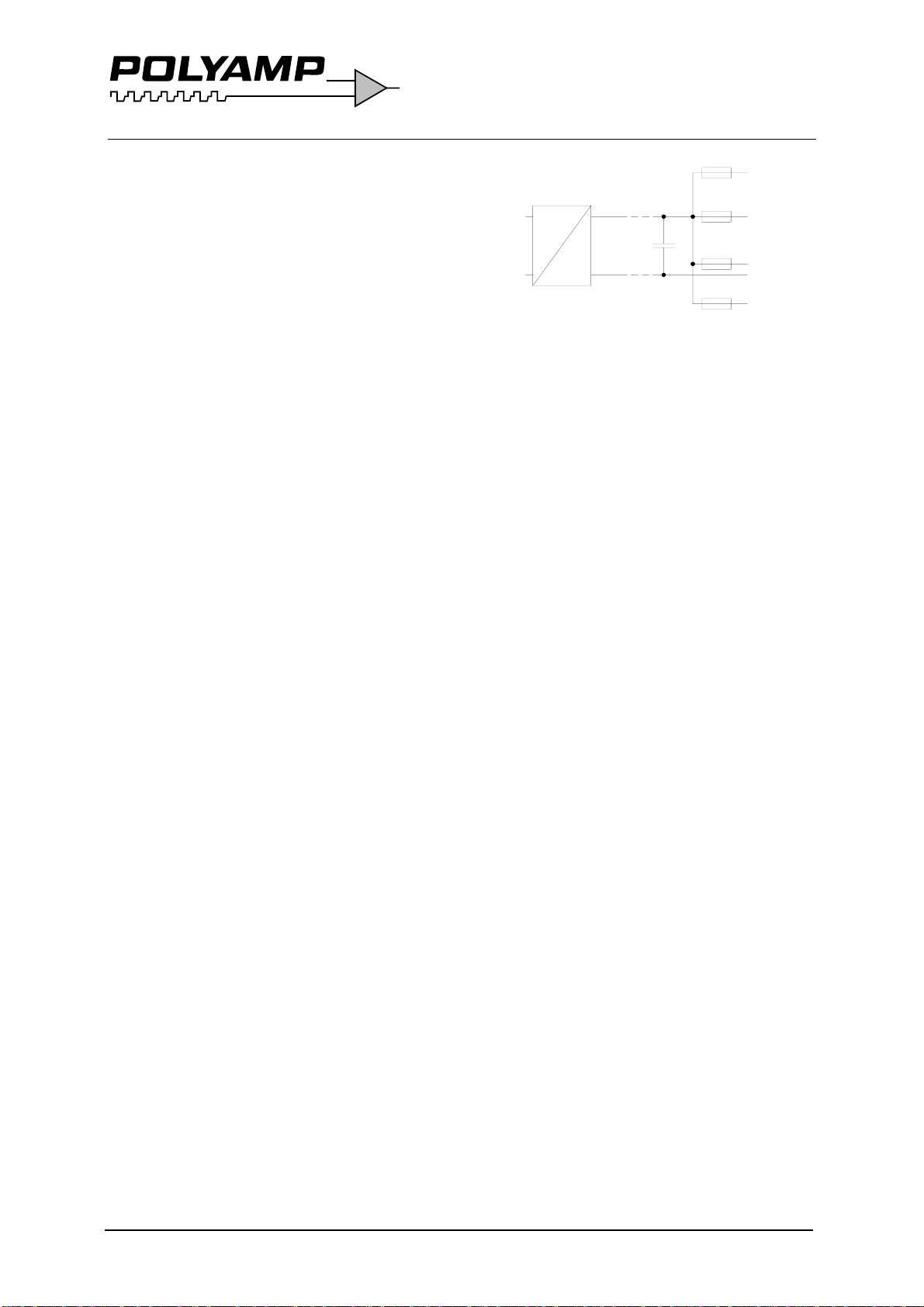

Input, output and case are galvanically

separated from each other. You can thus

choose how you want the system connected.

The output can be connected with any pole to

protective earth or as a floating output with

max ±150V to the protective earth. It means

that maximum 3 units can be put in series.

The electrical safety system is a class I, which

means that protective earth has to be

connected. The 110 and 220 input code models

can also be used as class II equipment without

protective earth. Although units installed in

dirty environments shall be connected to

protective earth.

On 110 and 220 input code the feeding system

can be defined as Primary circuit (Max

250Va.c.) and as Secondary circuit.

On 24 and 48 input code the feeding system

can be defined as Secondary circuit voltage,

and SELV voltage.

The cables used for input and output feeding

shall be dimensioned to fit the fuse rating and

continuous current as well as intended ambient

temperature range and insulations demand due

to the voltage used.

The input is protected against reverse polarity

by combination circuit with inrush current

limit circuit. If reverse voltage occurs at

installation the converter will not start. The

reverse voltage will not cause damage to the

unit.

The input shall be fused with an approved fuse

with high breaking capacity. We recommend

following fuses ratings and fuses. Please note

that in installation class I with protective earth,

the fuse shall be on the pole not in connection

with the protective earth.

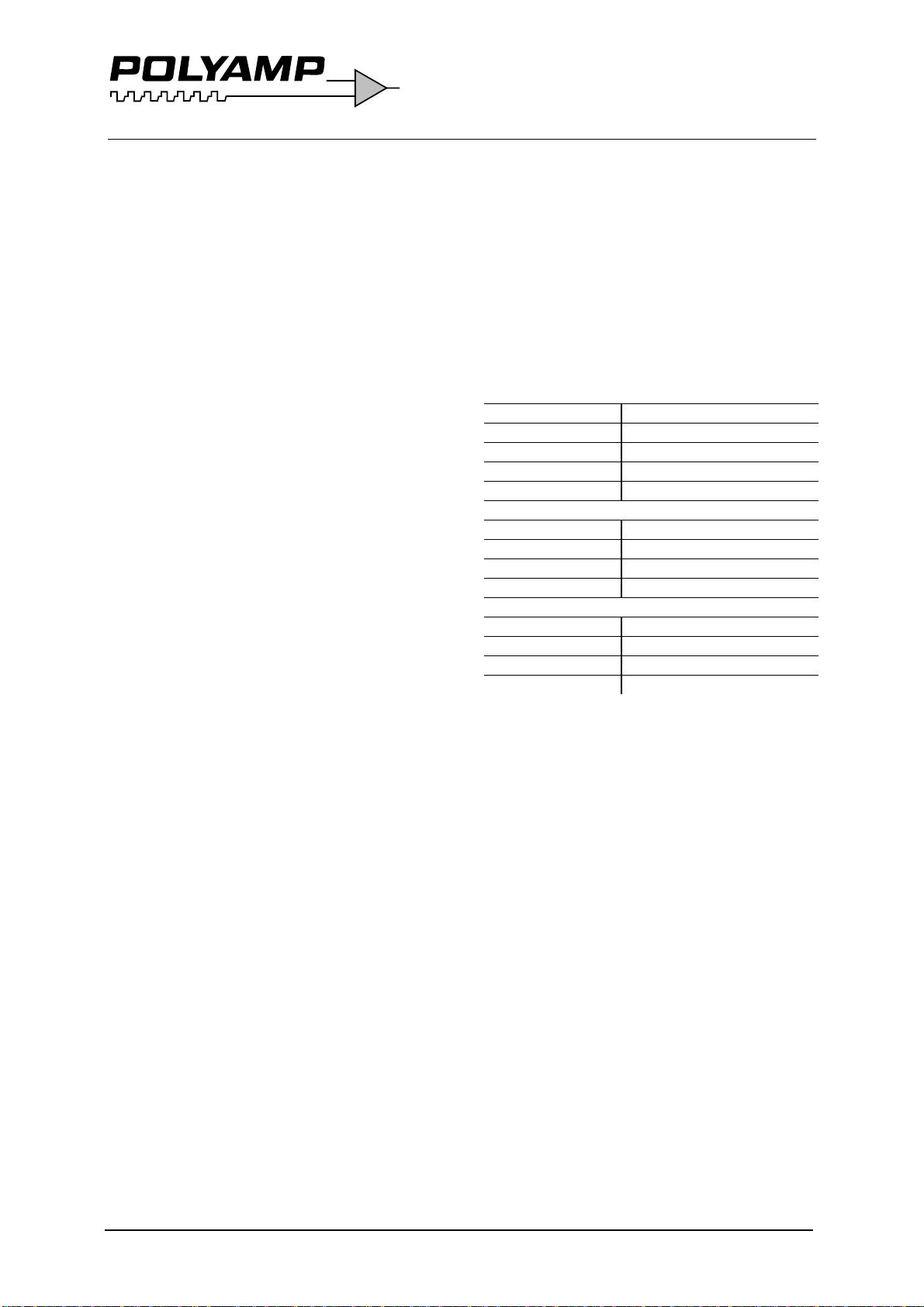

PC1000 input fuses

Input voltage code Time delay fuse

24 63 A, Siemens 3NA3 022

48 35 A, Siemens 3NA3 014

110 16 A, Siemens 3NA3 005

220 10 A, Siemens 3NA3 003

PC1400 input fuses

Input voltage code Time delay fuse

48 50 A, Siemens 3NA3 020

110 20 A, Siemens 3NA3 007

220 10 A, Siemens 3NA3 003

PC2000 input fuses

Input voltage code Time delay fuse

48 63 A, Siemens 3NA3 022

110 25 A Siemens 3NA3 010

220 16 A, Siemens 3NA3 005

Table 1. Recommended input fuses.

There are two reasons we do not include the

fuse.

1. DC-networks should be fused at the

distribution point to protect the cable.

2. Different applications require different

types of fuses.

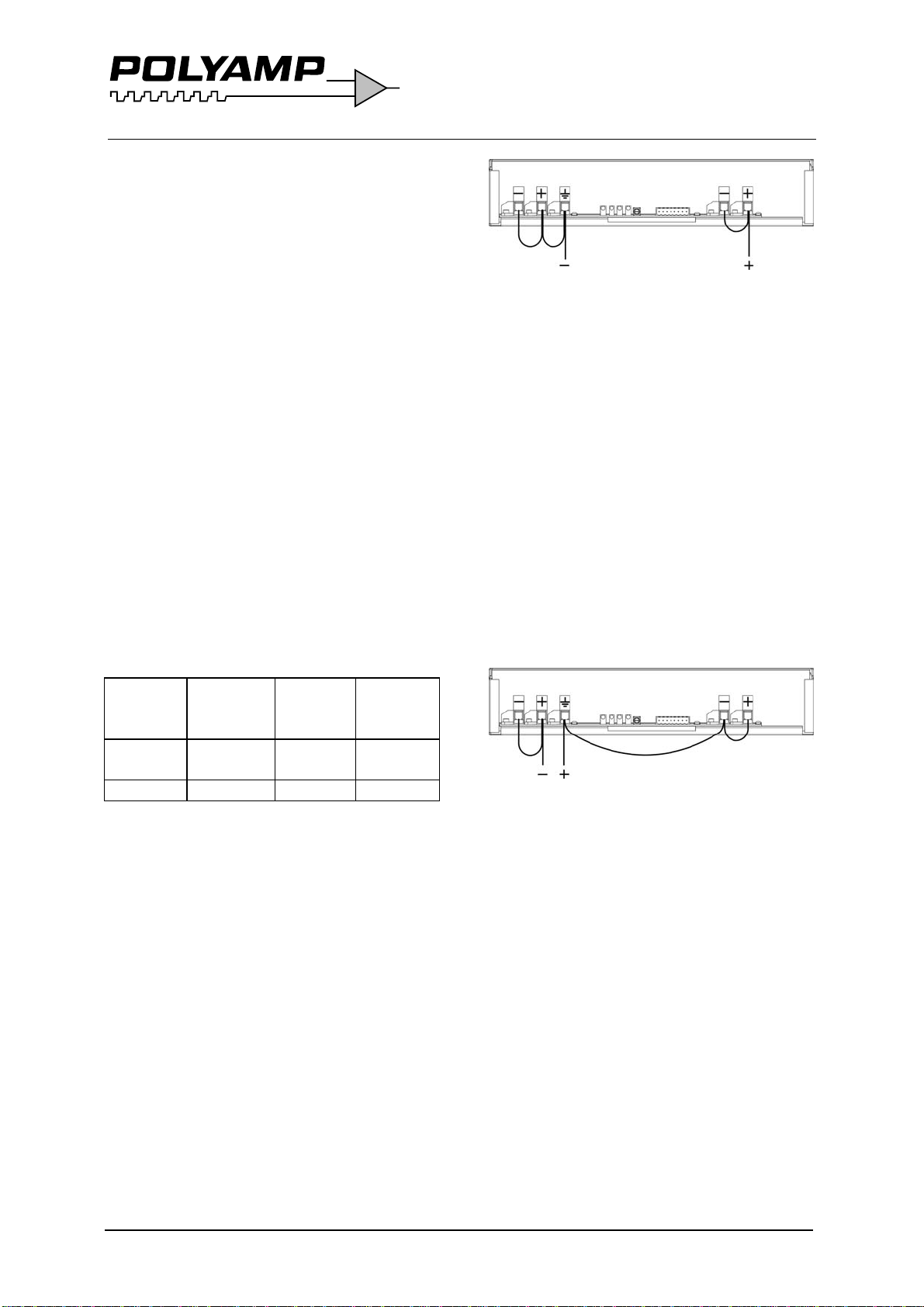

To meet the EMC specifications in the

enclosed “declaration of conformity” use

twisted-pairs for connecting input, output,

alarm, inhibit and voltage sense. Shielded

cables are not necessary.

If the converter is mounted in an electric

vehicle, an external series diode on the input is

recommended. Please contact your Polyamp

dealer.

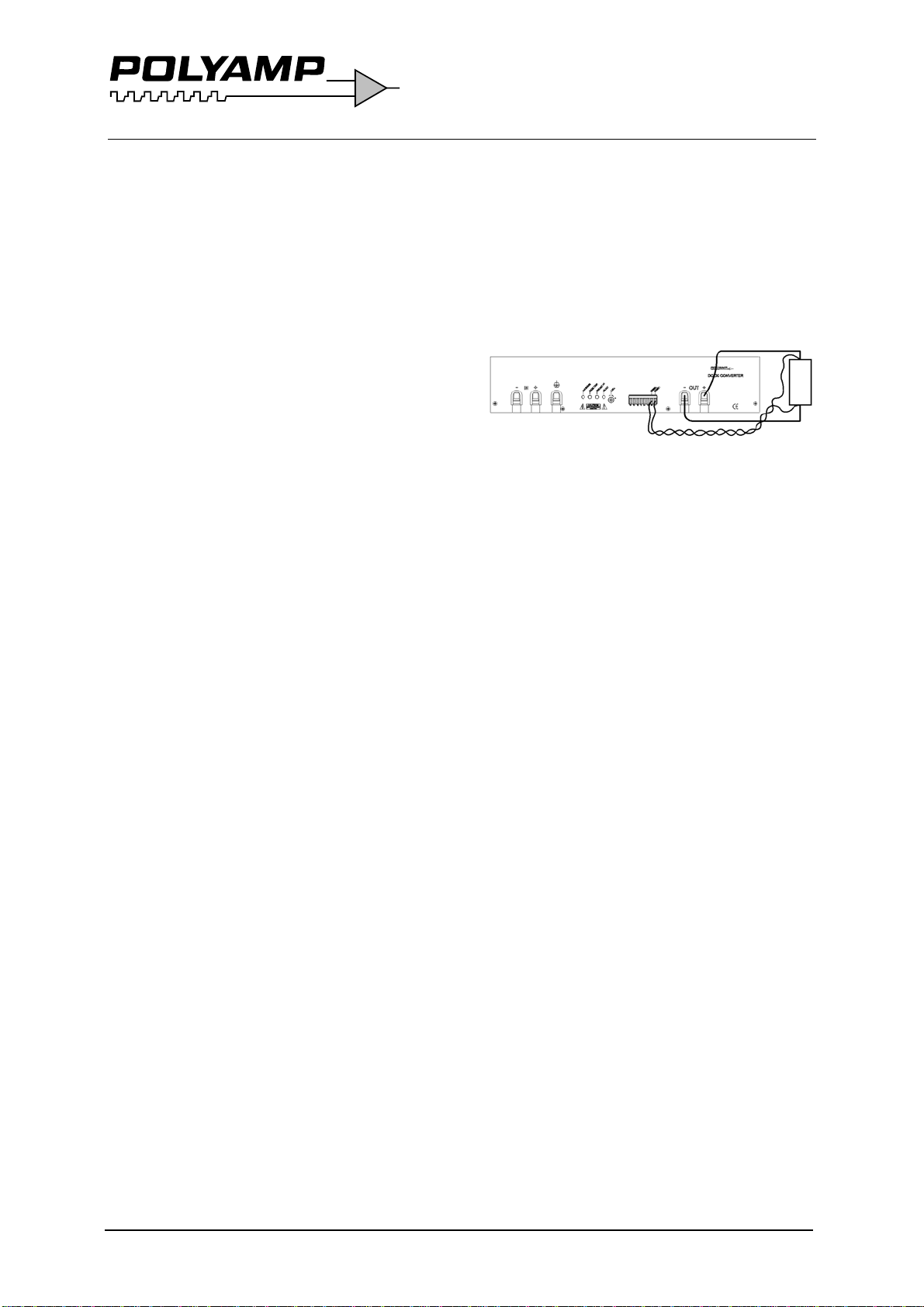

If the converter supplies a DC-motor, we

recommend an external parallel diode at the

motor poles to protect against reverse voltages.