User manual

PONSEL Ref.: NOTICE_ACTEON_2030_v002.doc V : 002 3/65

CONTENTS

1THE MEASURING SYSTEM................................................................................6

1.1

The basic system ..................................................................................................................................... 6

1.1.1

An O

2

and Temperature transmitter:.................................................................................................... 6

1.1.2

DO sensor............................................................................................................................................. 6

1.2

Accessories: ............................................................................................................................................. 7

1.2.1

Consumables........................................................................................................................................ 7

1.2.2

Accessories for a tank-mounted installation without cleaning system................................................. 7

1.2.3

Accessories for a tank-mounted installation with cleaning system...................................................... 7

1.2.4

Accessories for DO and temperature sensor in-pipe installation (PONCPC-O2T-P-10 or PONCPC-

OXYT-P-10)....................................................................................................................................................... 8

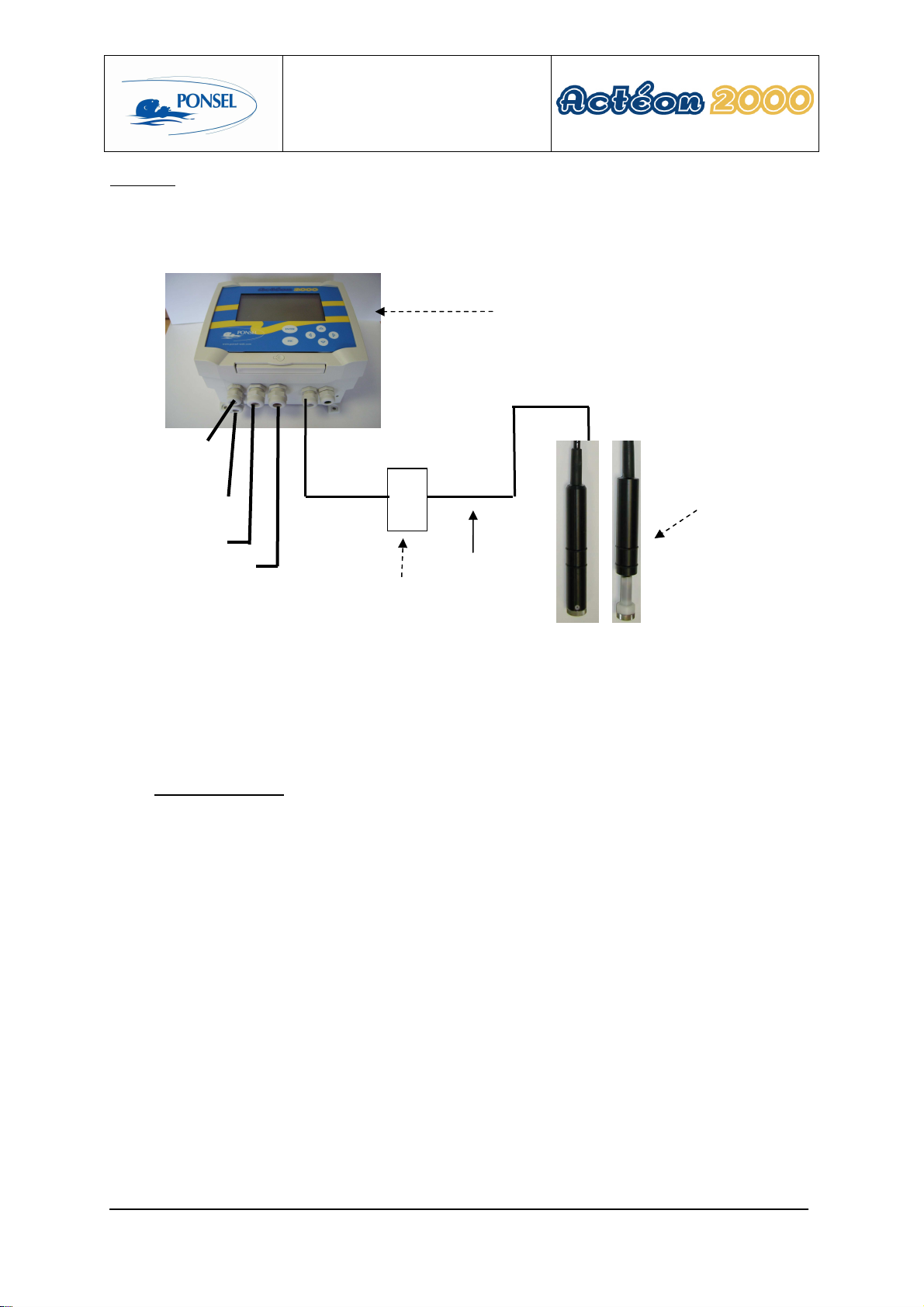

2INSTALLATION ...................................................................................................9

2.1

Mounting the ACTEON transmitter box.............................................................................................. 9

2.2

Connecting the ACTEON 2030 transmitter and DO sensor............................................................... 9

2.2.1

Acteon 2030 wiring:........................................................................................................................... 10

2.3

Tank-mounting:.................................................................................................................................... 10

2.3.1

Using the stand and protective hood.................................................................................................. 10

2.3.2

Installing the sensor with a sensor-holder perch (elbowed or straight) and nozzle (ref.: PONPPCC-O

or PONPPCD-O)............................................................................................................................................. 11

2.3.3

Installing an Elbowed Sensor-Holder Perch (ref: PONPPCC-CIR) or Straight Sensor-Holder Perch

(ref: PONPPCD-CIR) on QRPM (ref: PONSPFR and PONSPFR2)............................................................ 14

2.3.4

Installing a DO sensor cleaning system ............................................................................................. 15

2.4

In-pipe installation:............................................................................................................................... 16

3ACTEON 2010 TRANSMITTER.........................................................................17

3.1

Control console:.................................................................................................................................... 17

4BLOCK DIAGRAM OF ACTEON 2030 MENUS:...............................................18

5THE MEASUREMENT WINDOW.......................................................................19

6CALIBRATING THE ACTEON 2030..................................................................20

6.1

Calibrating the sensors:........................................................................................................................ 20

6.1.1

Two point DO sensor calibration (complete calibration):.................................................................. 21

6.1.2

DO sensor slope adjustment:.............................................................................................................. 24

6.1.3

Returning to measurement theoretical calibration: ............................................................................ 26

6.1.4

Two point temperature sensor calibration (complete calibration):..................................................... 27

6.1.5

Adjusting the temperature sensor slope: ............................................................................................ 30

6.1.6

Returning to temperature measurement theoretical calibration:......................................................... 32

6.2

DO sensor calibration error message information............................................................................. 33

6.2.1

Clean water and sulphite calibration error ......................................................................................... 33

6.2.2

Calibration error during air exposure................................................................................................. 33

6.3

Temperature sensor calibration error message information............................................................ 33

6.3.1

0°C calibration error .......................................................................................................................... 33

6.3.2

Ambient water calibration error......................................................................................................... 34

7VIEWING MEASUREMENT HISTORY..............................................................35