User manual

PONSEL Référence : NOTICE_ACTEON_2050_v001 V : 002 3/67

CONTENTS

1THE MEASURING SYSTEM................................................................................6

1.1

The basic system ..................................................................................................................................... 6

1.1.1

A Suspended Solids (SS) -Temperature transmitter: ........................................................................... 6

1.1.2

A SS sensor.......................................................................................................................................... 6

1.1.3

Temperature sensor.............................................................................................................................. 6

1.2

Accessories: ............................................................................................................................................. 7

1.2.1

Consumables........................................................................................................................................ 7

1.2.2

Accessories for a tank-mounted installation without cleaning system................................................. 7

1.2.3

Accessories for MES5 (PONCIR-MES5-10) and Temperature sensor in-pipe installation ............... 7

2INSTALLATION ...................................................................................................8

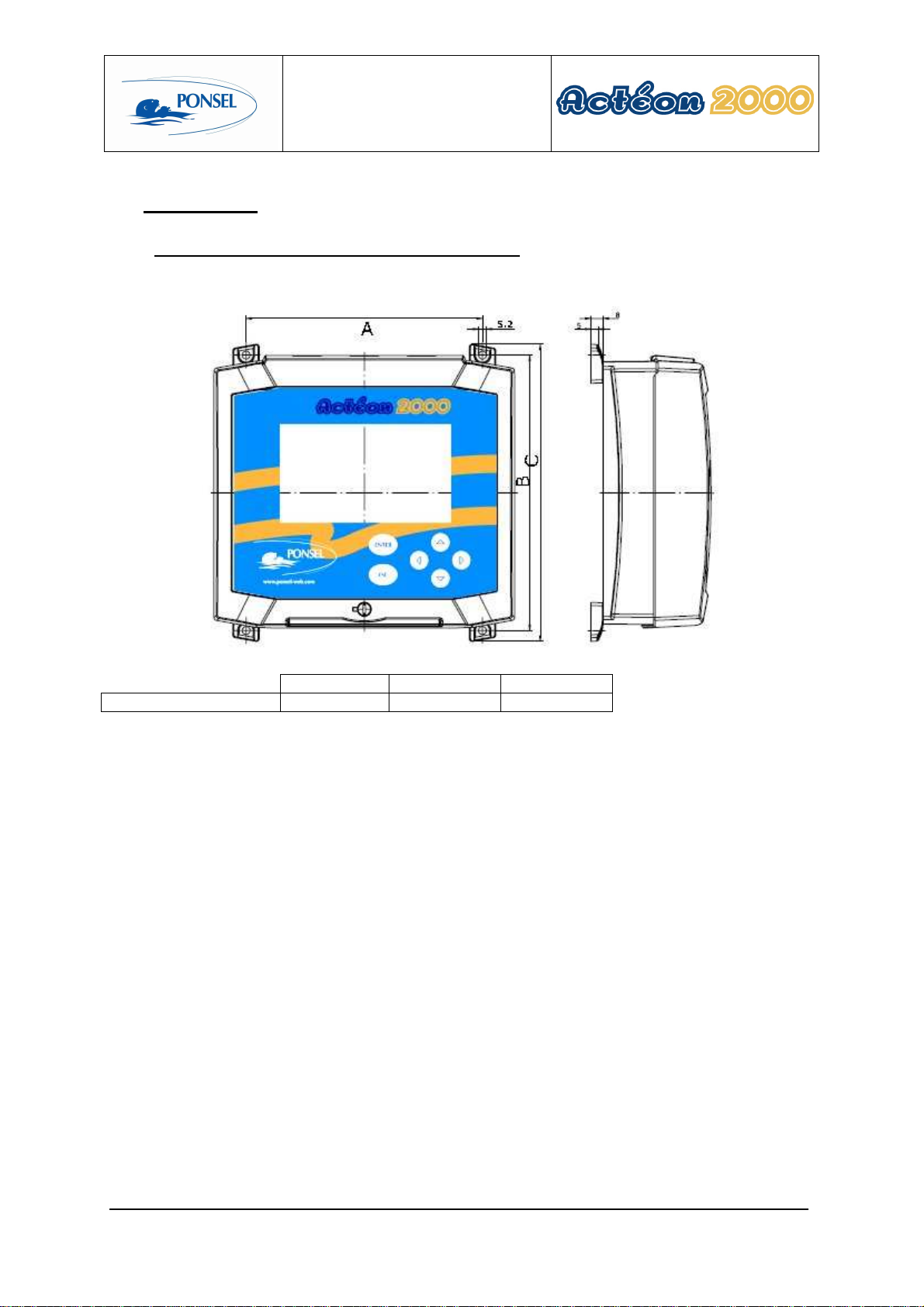

2.1

Mounting the ACTEON 2050 transmitter box..................................................................................... 8

2.2

Connecting the ACTEON 2050 transmitter and MES and Temperature sensors............................ 9

2.2.1

Acteon 2050 wiring:........................................................................................................................... 10

2.3

Tank-mounting:.................................................................................................................................... 11

2.3.1

Using the stand and protective hood.................................................................................................. 11

2.3.2

Installing the sensor in the sensor-holder perch (elbowed or straight) (PONPPCC-CIR or

PONPPCD-CIR).............................................................................................................................................. 11

2.3.3

Installing an Elbowed Sensor-Holder Perch (ref: PONPPCC-CIR) or Straight Sensor-Holder Perch

(ref: PONPPCD-CIR) on QRPM (ref: PONSPFR and PONSPFR2)............................................................ 13

2.4

In-pipe installation:............................................................................................................................... 14

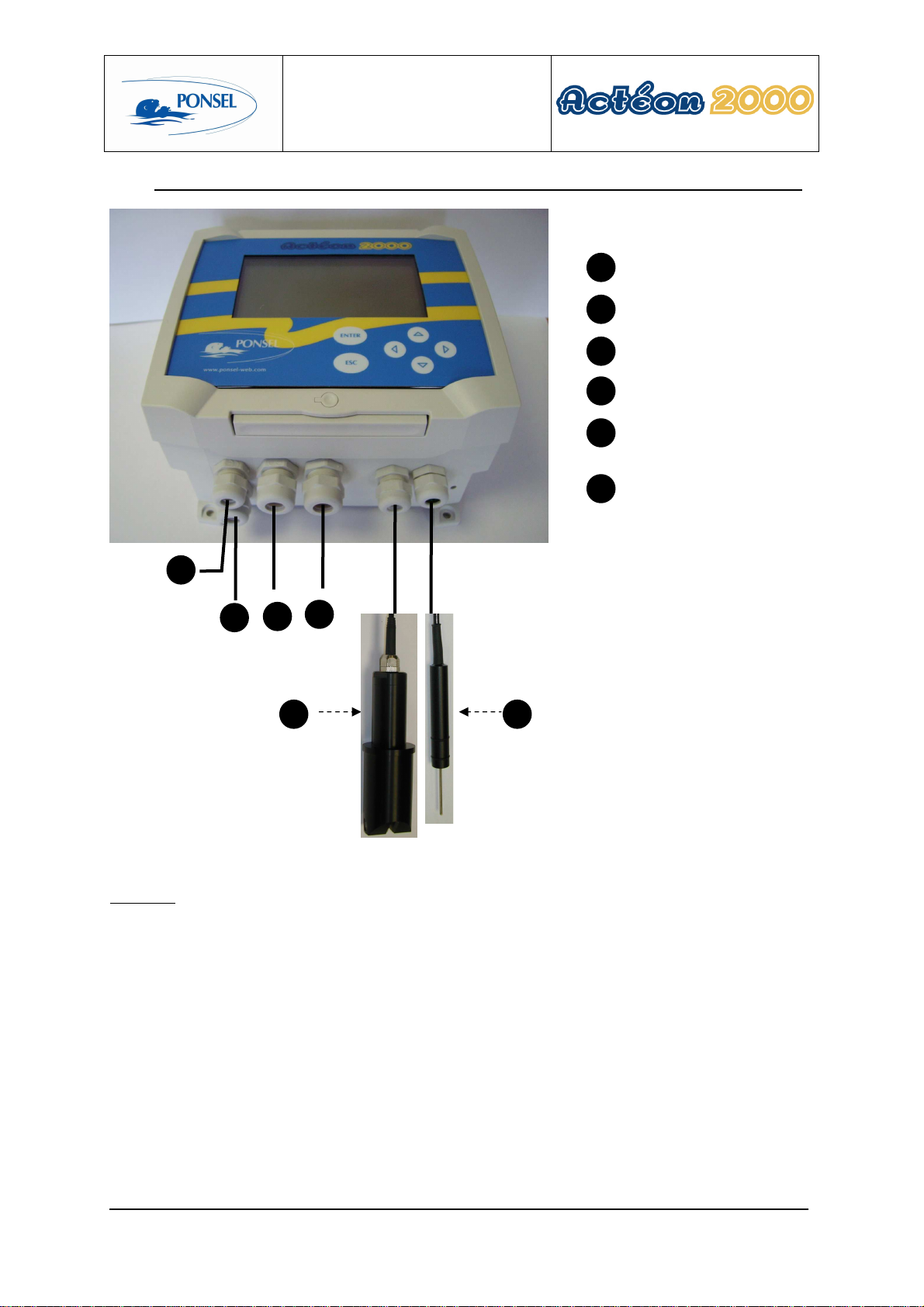

3ACTEON 2050 TRANSMITTER.........................................................................15

3.1

Control console:.................................................................................................................................... 15

4BLOCK DIAGRAM OF ACTEON 2050 MENUS:...............................................16

5THE MEASUREMENT WINDOW.......................................................................17

6CALIBRATING THE ACTEON 2050..................................................................18

6.1

Calibrating the sensors:........................................................................................................................ 19

6.1.1

Two point SS sensor calibration (immediate calibration):................................................................. 19

6.1.2

Two point SS sensor calibration (differed calibration):..................................................................... 22

6.1.3

SS sensor slope adjustment:............................................................................................................... 27

6.1.4

Returning to SS measurement theoretical calibration:....................................................................... 29

6.1.5

Two point temperature sensor calibration (complete calibration):..................................................... 30

6.1.6

Adjusting the temperature sensor slope: ............................................................................................ 33

6.1.7

Returning to temperature measurement theoretical calibration:......................................................... 35

6.2

SS sensor calibration error message.................................................................................................... 36

6.2.1

CLEAN WATER calibration error .................................................................................................... 36

6.2.2

SLUDGE calibration error................................................................................................................. 36

6.3

Temperature sensor calibration error message information............................................................ 37

6.3.1

0°C calibration error .......................................................................................................................... 37

6.3.2

Ambient water calibration error......................................................................................................... 37

7VIEWING MEASUREMENT HISTORY..............................................................38