6

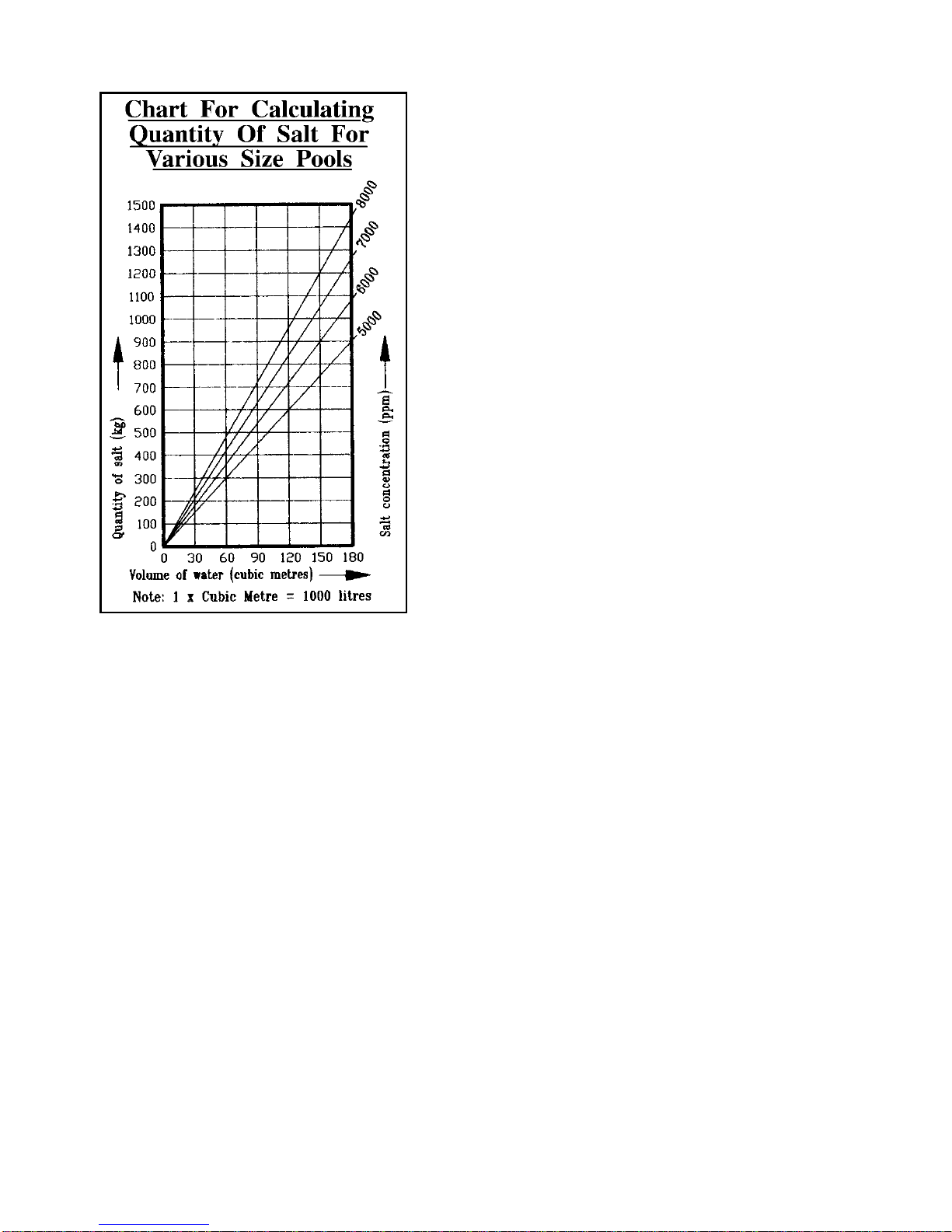

To find he correc amoun of sal using his char :

1. Mark the point along the bottom edge which

corresponds with the calculated volume of

water in the pool.

2. Draw a vertical line from this point which

intersects the inclined lines showing salt

concentrations.

3. From the point where this vertical line

intersects the inclined line showing the chosen

salt concentration, draw a horizontal line

across to the left. Where this line crosses the

left side of the graph, the quantit of salt in

kilograms will be indicated.

Adding Sal And S abiliser To The Pool

If ou are quite sure of our calculations then add

the calculated amount of salt directl to our pool.

Warning:

Onl swimming pool grade salt (Sodium

Chloride) should be used. Inferior grades ma

lead to problems with the chlorinator cell.

Do not attempt to add salt via the surface skimmer

as this can cause damage to the filtration s stem.

An suction t pe pool cleaners should also be

disconnected before adding salt.

At the same time add the recommended quantit of cyanuric acid s abiliser. This is

most important as our Surechlor will not operate efficientl during summer months

without the correct level of stabiliser in the pool. Recommended level for maximum

efficienc is between 30 and 60 mg/l (ppm). pH buffer can also be added now if required.

Dissolving The Sal

Before attempting to operate the Surechlor 4000 cell, the salt must be allowed to full

dissolve in the pool water. This is the best achieved (after allowing sufficient time for

the glue on the pipe fittings to set properl ) b running the filter pump without the cell

operating for 24 hours to circulate the water.

To assist the dissolving of the salt, regularl brush the floor of the pool with a pool

broom until the salt has dissolved.

When The Sal Has Dissolved

With the pump still operating, increase the Chlorine Control to maximum. The Monitor

should indicate 10 bars.

Your Surechlor is now generating chlorine!

Should the Output Monitor read low with the Chlorine Control at maximum, do not be

concerned, just allow the s stem to run for another 24-48 hours. If the displa

continues to give a low reading after this period, press the Salt Test (with the s stem

running) and note the displa message.

If the water temperature is around 25°C and the cell is relativel clean, this reading will

indicate salt concentration. If it confirms the salt level is low then add more salt

graduall over a period of da s until the displa reads normal. Continue brushing floor

of pool until the additional salt has dissolved.