7301361-100 Rev. D

Does not flush

Poor or sluggish flush

Toilet leaks

Toilet does not shut off

a. Water supply valve closed.

b. Supply line blocked.

c. Flush valve chain too loose or disconnected.

d. Sand or debris lodged in water control.

a. Bowl water level too low.

b. Supply valve partly closed.

c. Partially clogged trapway and/or drain pipe and/or vent.

d. Supply pressure too low.

e. Flush valve chain too tight, holding flush valve open.

a. Poor supply line connection.

b. Poor bowl to tank/floor connection.

a. Flush valve seal leaking or deformed.

b. Sand or debris lodged in water control.

a. Open valve and allow water to fill tank.

b. Shut off water supply, disconnect supply line and inspect all

gaskets and washers. Reassemble. Also, see Fluidmaster

maintenance. (see Step 12)

c. Readjust chain length as required.

d. Shut off water supply. Remove cap and clean as per Step 12.

a. Check that refill tube is connected to water control and

inserted into tank overflow without being kinked or damaged.

b. Open supply valve fully. Be sure that proper supply tube size is used.

c. Remove obstruction. Consult a plumber if necessary.

d. Normal supply pressure must be at least 20 psi.

e. Readjust chain length as needed. Review Step 9A.

a. Review Step 8a and 8b of installation procedure.

b. Review Step 4 through 6 of installation procedure.

a. Clean debris from seal surface. Replace flush valve seal as needed.

b. Shut off water supply. Remove cap and clean as per Step 12.

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

- 5 -

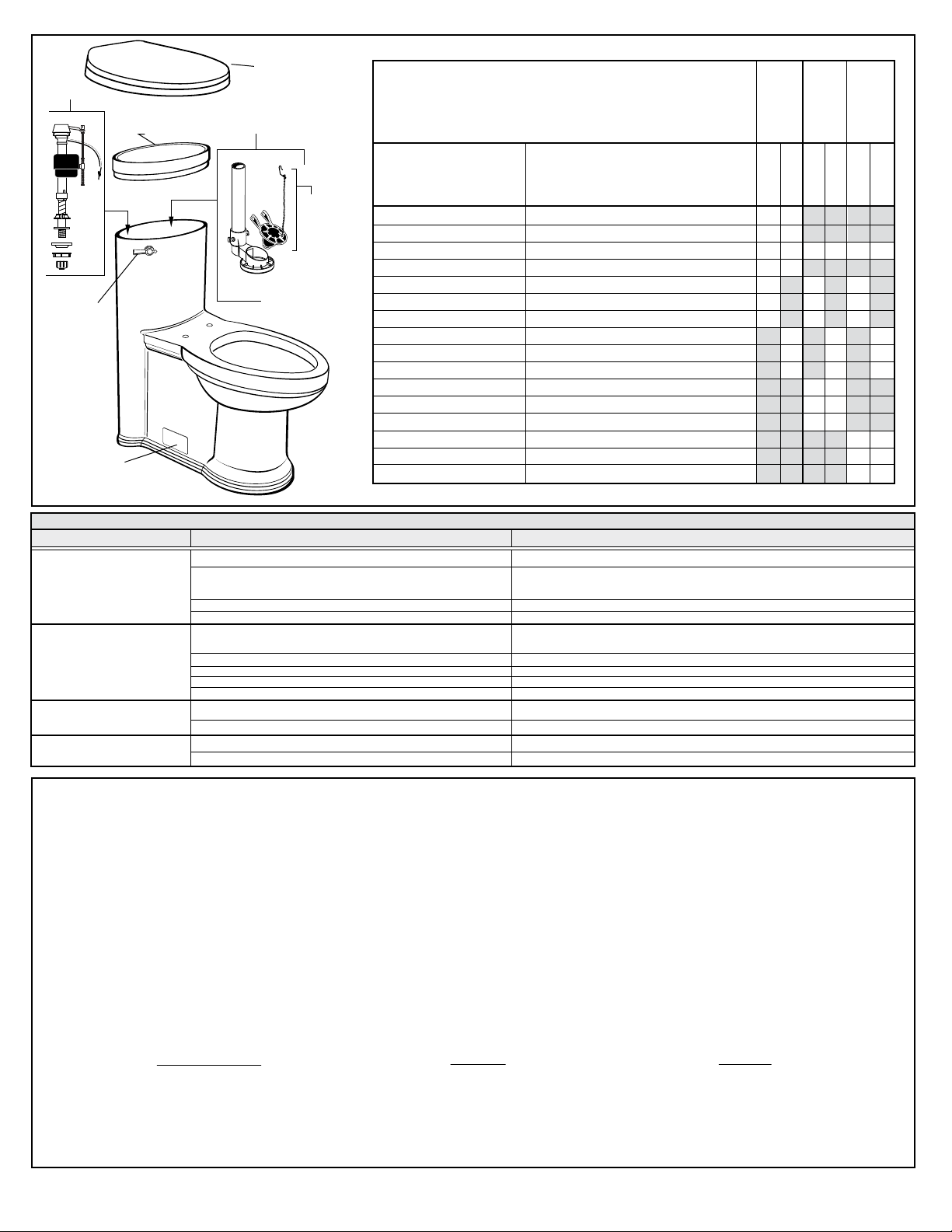

SEAT AND

COVER

(INCLUDES

MTG. KIT)

TRIP

LEVER

BOLT

CAPS

FLAPPER

ASSEMBLY

FLUSH

VALVE

INLET VALVE

TANK

COVER

LIMITED WARRANTY

If inspection of this Porcher plumbing product, inclusive of all china components, within ten years after its initial purchase, confirms that it is defective in materials or

workmanship, Porcher will repair or, at its option, exchange the product for a similar model.

If inspection of this Porcher plumbing product, inclusive of all mechanical components, within five years after its initial purchase, confirms that it is defective in materials or

workmanship, Porcher will repair or, at its option, exchange the product for a similar model.

If inspection of this Porcher plumbing product, inclusive of all toilet seat components, within one year after its initial purchase, confirms that it is defective in materials or

workmanship, Porcher will repair or, at its option, exchange the product for a similar model.

This warranty does not apply to local building code compliance. Since local building codes vary considerably, the purchaser of this product should check with a local

building or plumbing contractor to insure local code compliance before installation.

This warranty shall be void if the product has been moved from its initial place of installation; if it has been subjected to faulty maintenance, abuse, misuse, accident or

other damage; if it was not installed in accordance with Porcher's instructions; or if it has been modified in a manner inconsistent with the product as shipped by Porcher.

This warranty DOES NOT COVER any damage caused by the use of in-tank cleaners.

Porcher's option to repair or exchange the product under this warranty does not cover any labor or other costs of removal or installation, nor shall Porcher be responsible

for any other incidental or consequential damages attributable to a product defect or to the repair or exchange of a defective product, all of which are expressly

excluded from this warranty. (Some states or provinces do not allow the exclusion or limitation of implied warranties, so this exclusion may not apply to you.)

This warranty gives you specific legal rights. You may have other statutory rights that vary from state to state or from province to province, in which case this warranty does

not affect such statutory rights.

For service under this warranty, it is suggested that a claim be made through the contractor or dealer from or through whom the product was purchased, or that a service

request (including a description of the product model and of the defect) be sent to the following address:

REPAIR PARTS LIST

NOTE: "XXX" represents color options.

Specify when ordering.

DESCRIPTION

ARCHIVE

CHAPEAU

PORCHER

SOLUTIONS

COMPONENT

1.6 GPF

1.28 GPF

Tank Cover, Archive

Slow Close Seat, Archive

Bolt Cap Kit

Trip Lever, Archive

Inlet Valve - 1.6 GPF

Flush Valve - 1.6 GPF

Flapper Assembly - 1.6 GPF

Inlet Valve - 1.28 GPF

Flush Valve - 1.28 GPF

Flapper Assembly - 1.28 GPF

Tank Cover, Chapeau

Trip Lever, Chapeau

Toilet Seat, Chapeau

Tank Cover, Porcher Solutions

Slow Close Seat, Porcher Solutions

Trip Lever, Porcher Solutions

80920-60-XXX

70920-00-XXX

7381073-XXX0A

81920-00-XXX

738565-439.0070A

738942-100.0070A

738920-100.0070A

738565-438.0070A

738942-102.0070A

7381043-400.0070A

80970-60.XXX

81970-00.XXX

70820-00.XXX

86010-00.XXX

70320-00.XXX

80010-00.XXX

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

1.6 GPF

1.28 GPF

1.6 GPF

1.28 GPF

In the United States:

American Standard Brands

P.O. Box 6820

Piscataway, New Jersey 08855

Attention: Director of Consumer Affairs

For residents of the United States, warranty

information may also be obtained by calling

the following toll free number: (800) 442-1902

www.americanstandard.com

In Canada:

AS Canada ULC

5900 Avebury Rd.

Mississauga, Ontario

Canada L5R 3M3

Toll Free: (800) 387-0369

www.americanstandard.ca

In Mexico:

American Standard B&K Mexico

S. de R.L. de C.V.

Via Morelos #330

Col. Santa Clara

Ecatepec 55540 Edo. Mexico

Toll Free: 01-800-839-1200

www.americanstandard.com.mx