22

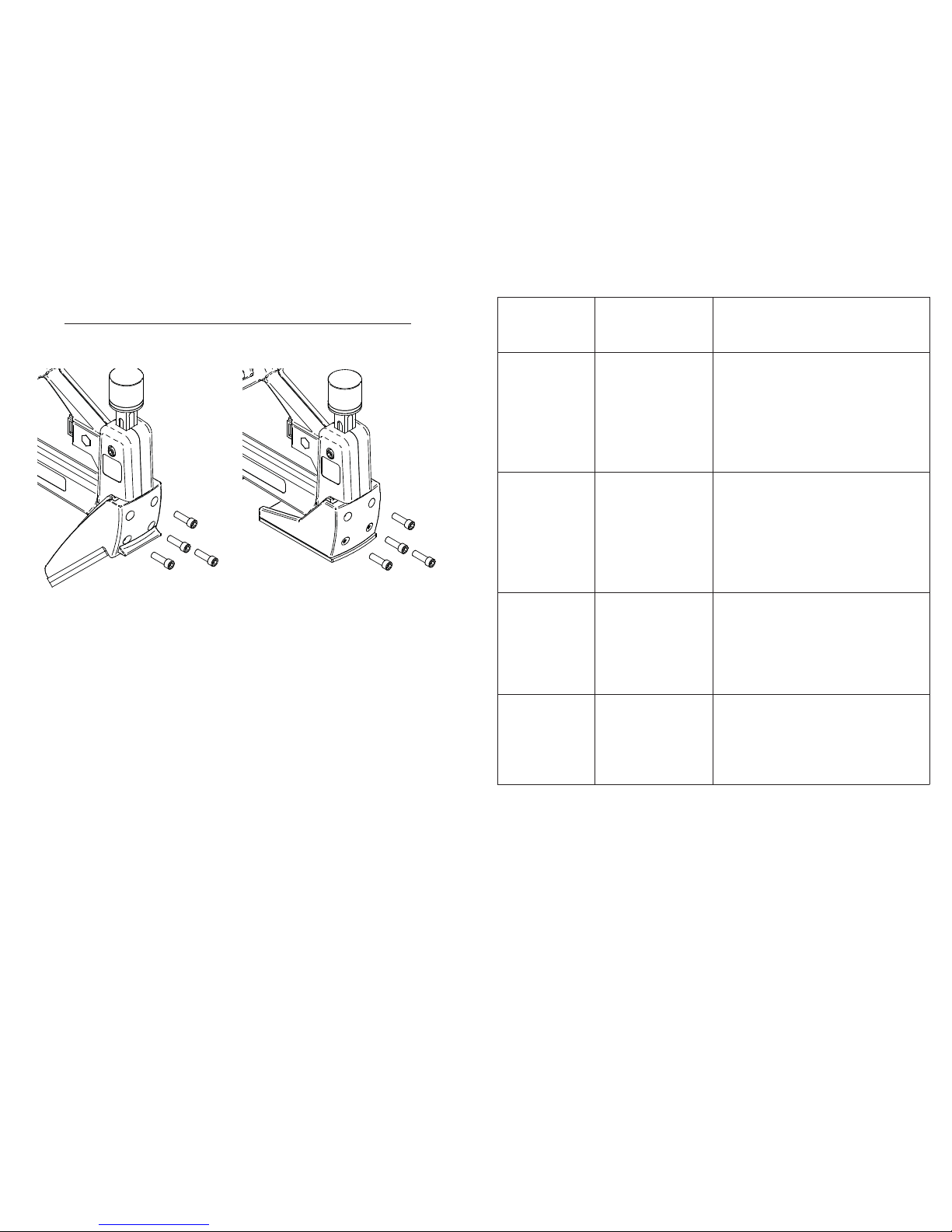

The first two strips of flooring and the last six (or strips that measure4. less than 13-1/2” from the wall) should be Face nailed with the Face

Nailing Shoe installed on the Porta-Nailer or by hand.

The Porta-Nailer MUST be held firmly, but not over-tightly in the5. hand so that the Porta-Nailer rests perfectly flat on the floor with the

lip of the shoe hanging over and against the edge of the strip being

nailed. As an aid to holding it flat against the floor, rest the toe of

your shoe on the rear of the Porta-Nailer Shoe.

DO NOT OVERPOWER THE PORTA-NAILER – Strike it firmly but6. NOT HARD, and then strike it again until the Ram returns. The Ram

does not return until the nail is properly seated.

Do not attempt to nail the last six strips (or strips that measure less7. than 13-1/2” from the wall) of flooring down with the Angled Shoe

installed. Switch and install the Face Nailing Shoe or face nail by

hand.

The Porta-Nailer system is user-friendly and following these simple

instructions, will insure a perfect hardwood flooring installation. Contact

our Customer Service Dept. (800) 634-9281 if you encounter flooring

which the Porta-Nailer does not properly position the fastener.

USE OF THE Porta-Nail

TONGUE & GROOVE

FLOORING

SUBFLOOR

JOIST

2" T-NAIL

MOISTURE

BARRIER

1-1/2" T-NAIL

CONCRETE

MOISTURE

BARRIER

TONGUE & GROOVE

FLOORING

SUBFLOOR

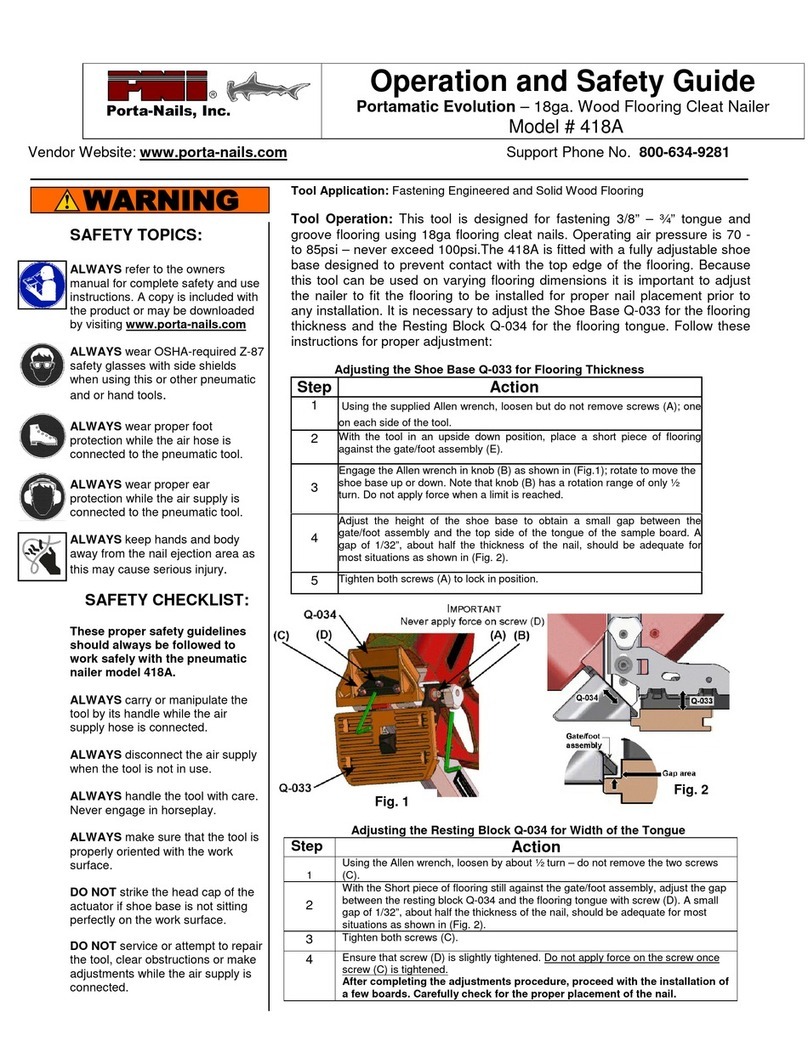

The Porta-Nail is 2” long and the PORTA-NAILER with the standard shoe

drives the nail into the Tongue and Groove Flooring at a 45-degree angle.

The orientation of the nail is as depicted in wood floor joist construction.

In applications where Tongue and Groove Flooring is laid over concrete or

Hydronic Heating Systems, the 1-1/2” or 1-3/16” Porta-Nail is used so that

the Nail will not protrude through the sub-floor. Refer to the “Porta-Nail

Application Chart” for proper Fastener usage. A Stainless Steel Porta-

Nail 2” long is available for applications requiring a non-corrosive nail.

3

PNI’s LIMITED ONE YEAR WARRANTY

PNI is proud of the products that it manufactures and warrants them to be free of

defects from workmanship and material for a period of 1 year from the date of

original purchase. In the unlikely event that a problem occurs, return the product

to our plant freight prepaid and allowed, so that a determination of the fault can be

made. If the fault is determined to be defective materials or workmanship, a no-

charge replacement or repair will be made, at our discretion. The product will be

returnedtoyoufreightprepaidandallowed. Thiswarrantydoesnotcoveraccidents,

abuse or misuse and in no case will PNI be liable for incidental or consequential

damages. No other warranty written or verbal is authorized.

Returns for warranty service or repair must have a RMA number prior to

returning; contact Customer Service at 800-634-9281.

Returns should be sent to:

Porta-Nails, Inc.

4235 US Hwy. 421 N.

Currie, NC 28435

Attention Service Dept.

SAFETY RULES FOR PORTA-NAILER

WEAR SAFETY GLASSES1. and safety shoes for protection against

foreign objects.

NEVER2. sit the Porta-Nailer in your hand or on your knee or any part

of your Body.

NEVER3. use a Hammer with a loose head or splintered handle.

USE ONLY4. nails from Porta-Nails, Inc.

REPLACE5. worn or damaged parts immediately.

APPLICATIONS

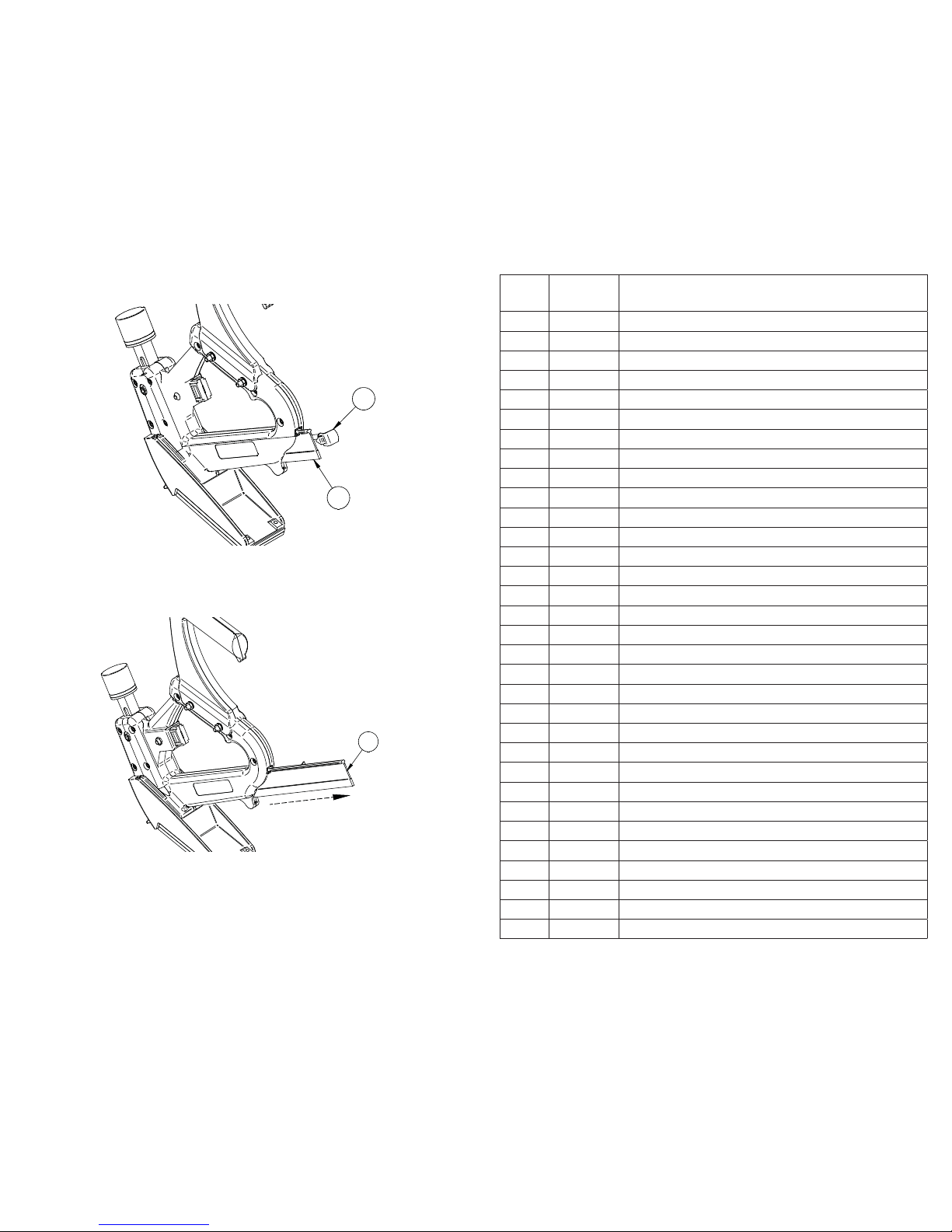

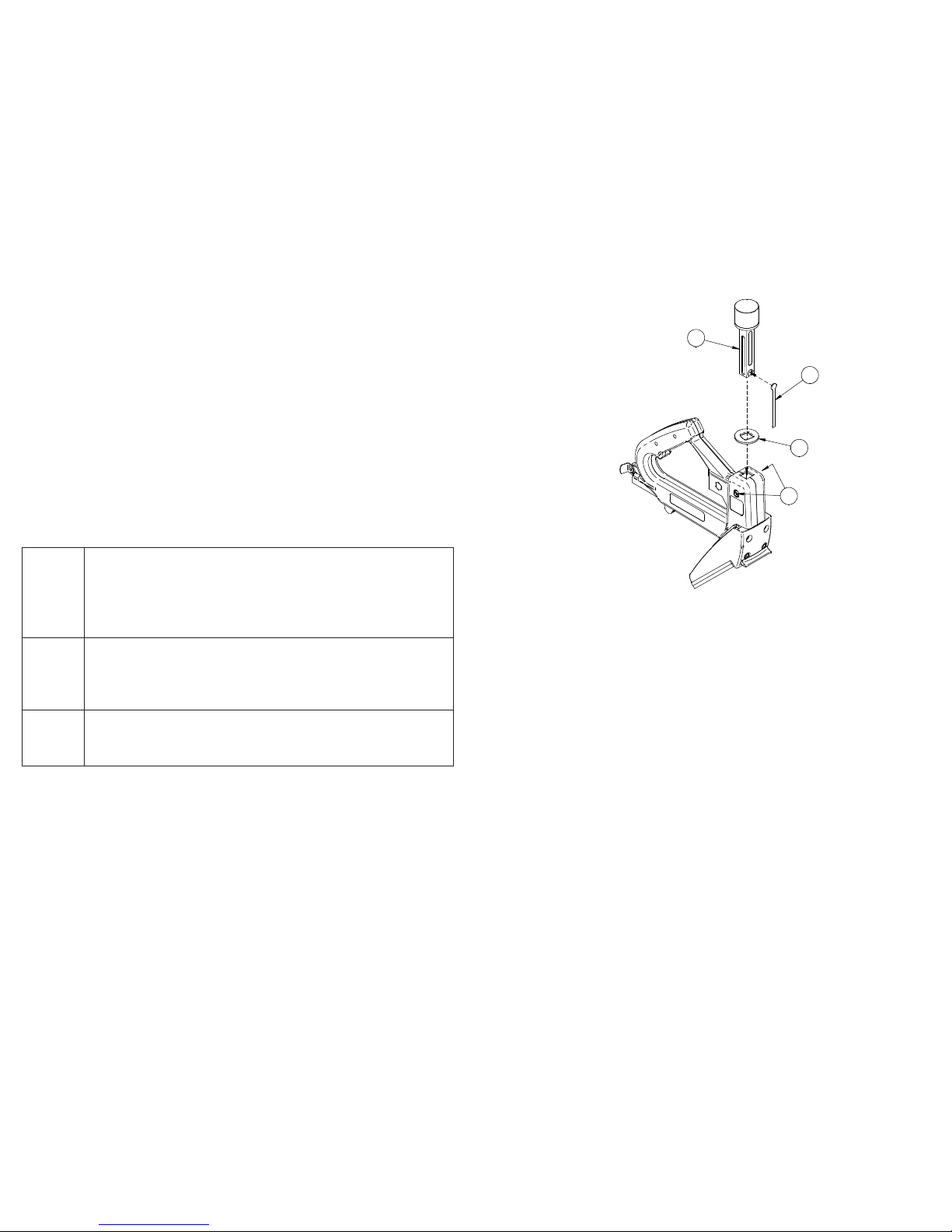

Your Model 402 Porta-Nailer is designed for Angle Nailing 5/8”,•

3/4”-33/32” Hardwood Tongue and Groove Flooring.

An Accessory Shoe is available (Sold Separately) for Face Nailing.•

(See Shoe Accessory Applications section)

An Accessory Shoe is available (Sold Separately) for Angle Nailing•

3/8” to 9/16” Flooring with the standard 2” Porta-Nail. (See Shoe

Accessory Applications section)

An Accessory Shoe is available (Sold Separately) for Angle Nailing•

5/8” Bamboo Tongue and Groove Flooring.

(See Shoe Accessory Applications section)

Contact our Customer Service Dept. if you encounter a flooring that•

our Nailer will not match up with.