1. Keep the workplace free from obstacles which could cause an accident. Ensure a clear working area of at least

1.5m is maintained to eliminate trip hazards from logs or tools.

2. Do not expose the Charger Logsplitter to rain. DO NOT use the Charger Logsplitter in damp or wet locations.

3. Keep children away from the Logsplitter. Children should never be allowed in the work place, or operate the

machine or tools.

4. Store your Charger Logsplitter in a dry and dust free environment.

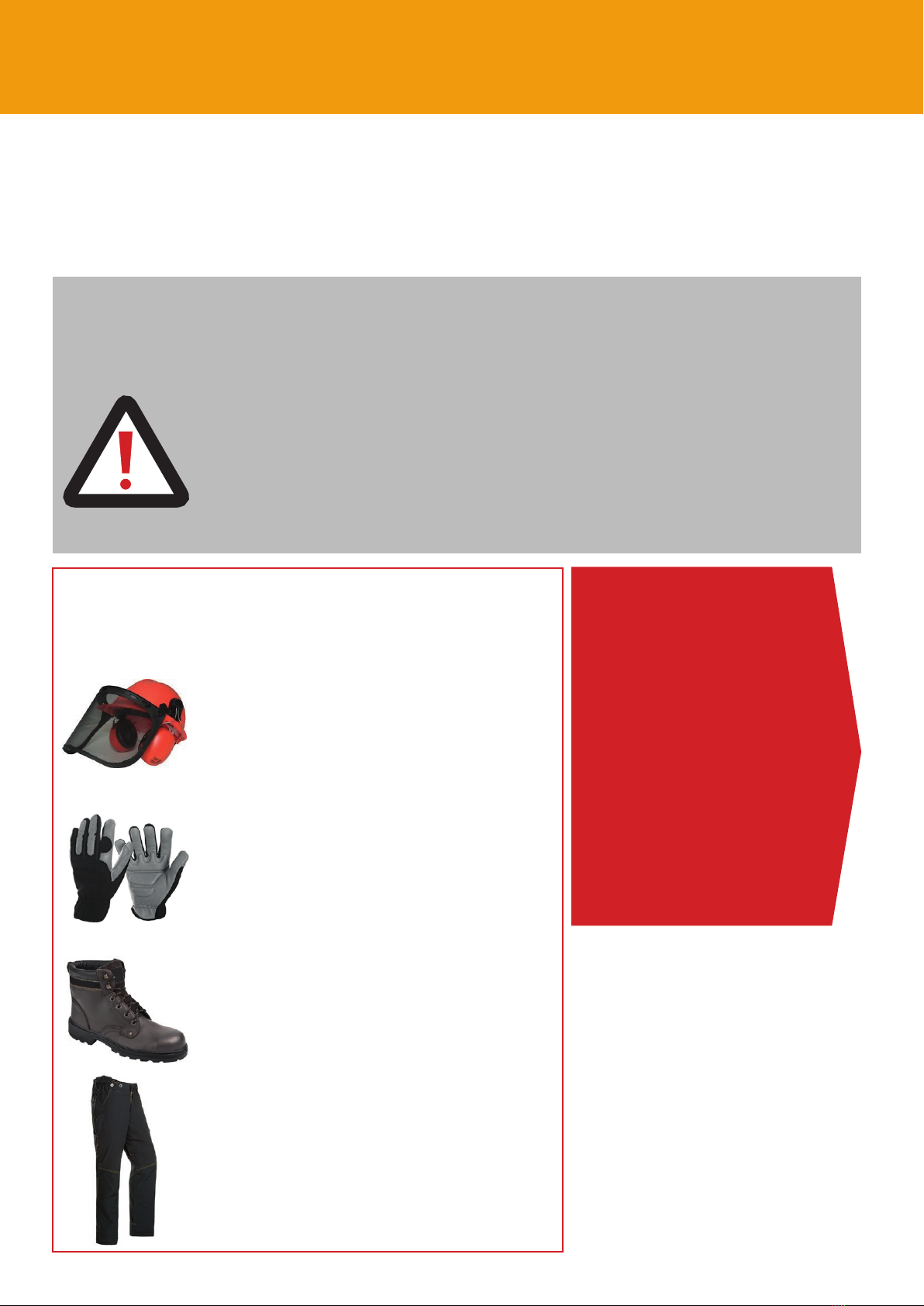

5. Dress appropriately. Do not wear loose clothing, jewellery or anything that could be caught by the moving parts.

Protective clothing and slip-resistant shoes are recommended when operating the machinery. Wear protective hair

covering to secure long hair.

6. Safety equipment must be used. When operating the Charger Logsplitter, protective strike-resistant certified

goggles, earplugs, working gloves and boots should be worn, see page 2.

7. Maintain the Charger Logsplitter and tools with care. Follow the instructions for lubricating, cleaning and parts

replacement. Keep handles clean, dry and free from oil and grease.

8. STAY ALERT! Look at what you are doing. Keep your judgement. Do not operate when you’re tired.

9. Check all parts. Before using the Charger Logsplitter, any damaged part should be carefully checked to determine

that it will operate properly and perform its intended function. Check all fasteners and tighten as necessary.

Any damaged parts should be repaired or replaced by a qualified technician.

10. Only genuine Charger Logsplitter accessories and parts can be used as replacements.

Using accessories and parts other than those recommended may cause the quality guarantee to be invalid.

11. Do not operate the machine if intoxicated with alcohol or drugs. If you’re taking prescribed drugs, make sure your

judgement and reactions are unaffected. If there is any doubt about this do not operate the Charger Logsplitter.

12. MAINTENANCE. For your own safety, the care and maintenance of the Charger Logsplitter should be on a regular basis.

13. WARNING! When operating, all persons, apart from operator, should keep at least 5m away from the Charger

machine, to avoid injuries by wood or debris. Only one operator is allowed to operate the machine at any one time.

14. CAPACITY. Do not try to split wood more than the specified size. If the wood can’t be split, take the wood out from the

machine and cut it into smaller sizes or split it by other means. For full specification and capacity, see page 9.

15. This machine can only be used to split wood. Splitting other material or using the Charger Logsplitter in other

ways may cause injuries or damage to property and invalidate any guarantee.

16. Care should be taken placing and removing logs from the log splitter as the splitting wedge has a sharp edge.

17. Always place the logs centrally on the cutting area. Hint: Logs split easier if the narrower diameter (towards top of

tree) is nearest the splitting wedge.

18. ATTENTION: the warnings, alerts and instructions in this manual cannot cover all situations. The operator must have

basic common sense and caution at all times.

19. ATTENTION: do not leave the Charger Logsplitter running unattended.

20. Use of a residual current device is recommended.

3

Important safety information

The Charger MUST be

operated from the back of

the machine as shown

This enables complete control of the

splitting process.

operated from the back of