3

Detail "B"

3" 8" 16"

2'-6"

.

912"

512"2"2"

8"6"

HEIGHT OF

WINCH

16"

7'-0"

MINIMUM DISTANCE

FROM BOTTOM

OF WINCH TO

FINISHED FLOOR

MINIMUM OF FOUR

ANCHORS REQUIRED -

SEE METHODS A, B OR C

IN DETAIL "C"

ANCHOR WOOD PAD / WINCH TO WALL

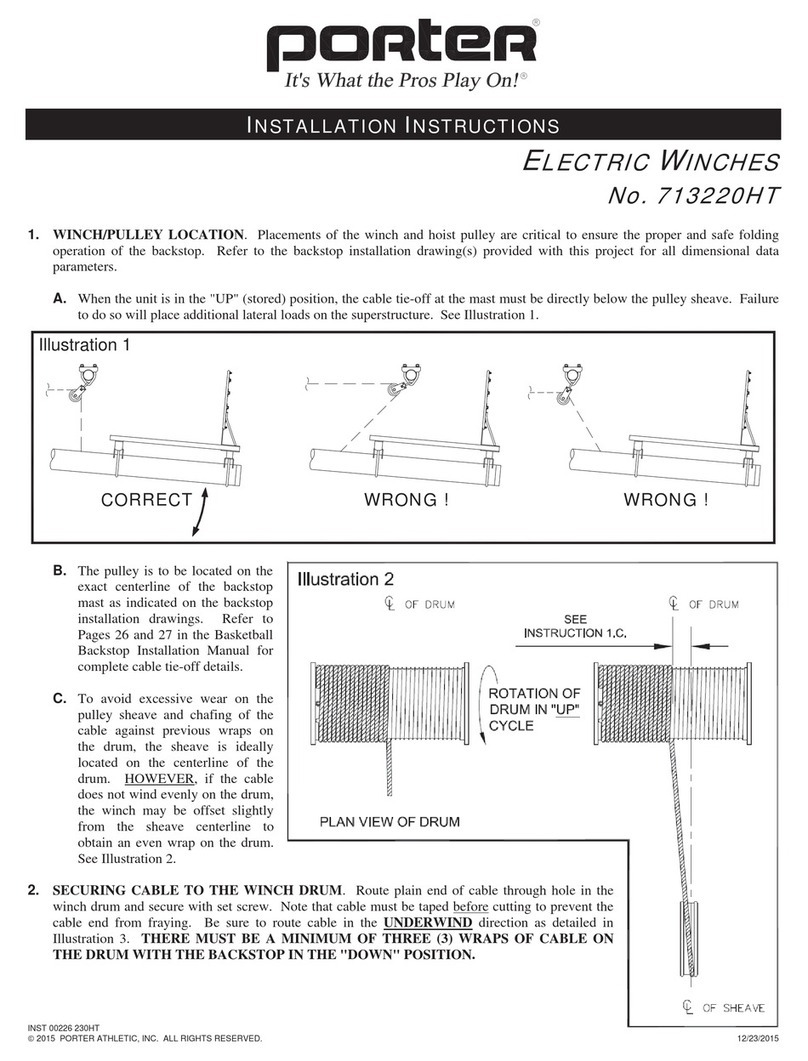

3. Before installing wood pad/winch assembly to

wall, verify exact location of winch with

owner or architect. In determining the exact

winch location, the following must be

considered:

The operator must have a clear view of

the equipment he/she is operating.

Anticipate path of cable between winch

and pulley(s). Structural members, lights,

ducts, drain pipes, etc. are potential

obstacles.

The path of the cable cannot cause it to

contact any part of the backstop mast

during the folding cycles.

Extensive cable travel will require

additional idler pulleys to support the

cable run.

Refer to separate installation manual supplied

with backstops, etc. for supplemental

information on winch location, cable routing,

etc.

4. Anchor wood pad/winch assembly (from Step

No. 2) to wall, using one of three suggested

anchor detail methods shown in Detail "C".

See Detail "B" for anchor spacing on wood

pad. Consult with architect or engineer to

verify wall capacity and to select appropriate

connections.

5. As an alternate, the winch can be mounted to

the face of a steel column (not shown).

EXISTING WALL (ANCHORS)

ADURING CONSTRUCTION EXISTING WALL (THRU-BOLT)

B C

Detail "C"

1/2"

GALVANIZED

MACHINE

BOLT

GALVANIZED

BUILDING

WASHER

212"

HOLD

FOR

WOOD

PAD

GALVANIZED

BUILDING

WASHER

1/2"

GALVANIZED

MACHINE

BOLT HOLD

FOR

WOOD

PAD

212"

ANCHORS

WITH

1/2" x 4" Lg.

LAG SCREW

WOOD PAD

(BY PORTER)

RAWL

MASONRY

ANCHORS

ONLY POSSIBLE AT TIME

THAT WALL IS CONSTRUCTED THRU-BOLTING FOR

CONCRETE OR MASONRY WALLS INSTALL ANCHORS INTO HORIZONTAL MORTAR JOINTS

ON SPACING AS SHOWN IN DETAIL "B". NEVER

INSTALL ANCHORS INTO OPEN CELL OF BLOCK.

NOTE - ALL HARDWARE FOR ATTACHING WOOD PAD TO WALL ARE BY OTHERS. VERIFY MATERIAL AND THICKNESS

OF WALL, AND USE APPROPRIATE HARDWARE / ANCHOR COMBINATION (MINIMUM 1/2" DIA. HARDWARE).