Page 4 For technical questions, please call 1-800-444-3353. Item 63190

SAFETY OPERATION MAINTENANCEASSEMBLY

moving parts, breakage of parts, mounting, and any

other condition that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced by a qualified technician

unless indicated elsewhere in this manual.

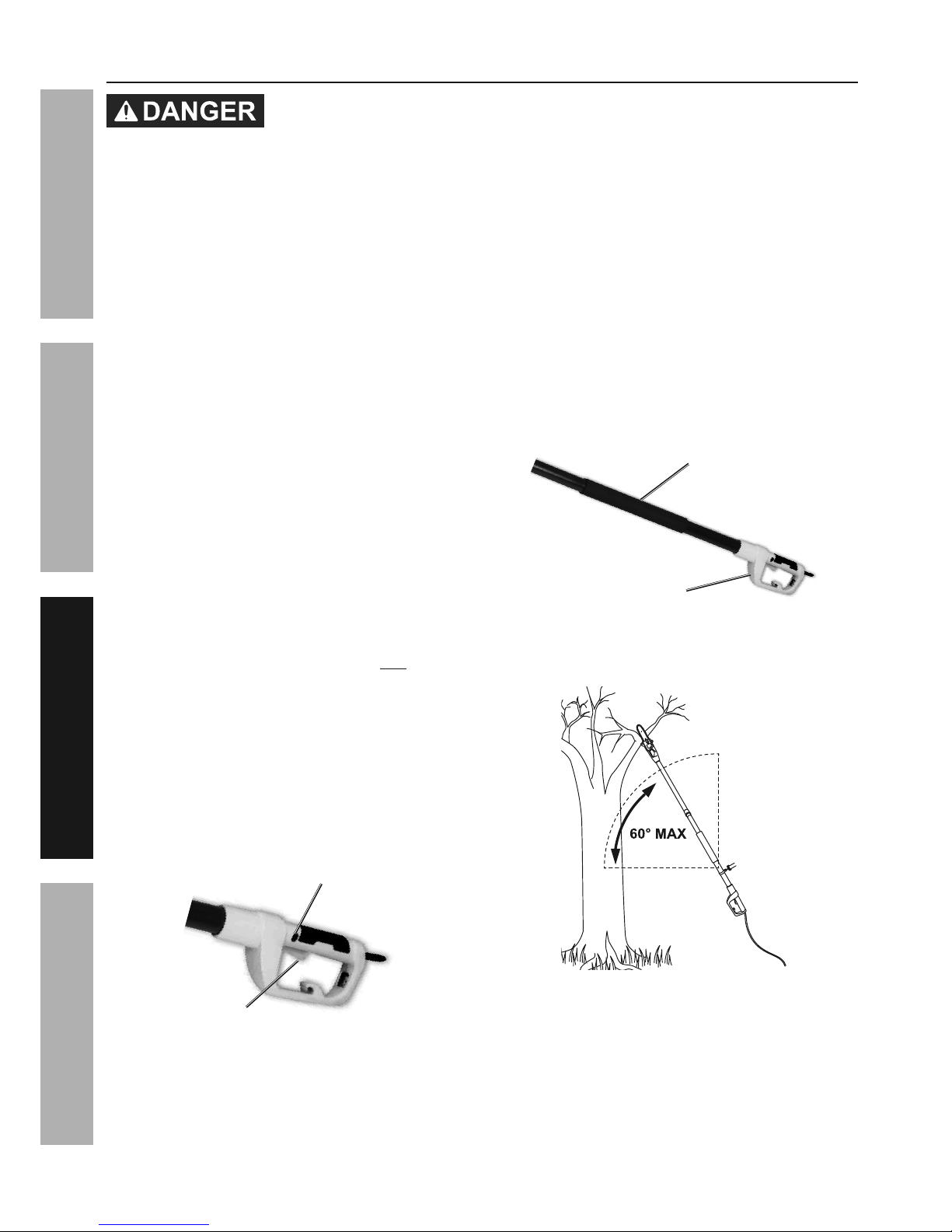

10. Carefully follow cutting procedures

explained in this manual. They are specifically

planned to reduce risk to the operator.

11. Lock pole in place securely

before using Pole Saw.

12. Maintain Appliance With Care - Keep cutting edge

sharp and clean for best performance and to reduce

the risk of injury. Follow instructions for lubricating

and changing accessories. Inspect appliance cord

periodically, and if damaged, have it repaired by

an authorized service facility. Inspect extension

cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

Vibration Hazard

This appliance vibrates during use. Repeated or long-term exposure to vibration may cause temporary or permanent

physical injury, particularly to the hands, arms and shoulders. To reduce the risk of vibration-related injury:

1. Anyone using vibrating appliances regularly

or for an extended period should first be

examined by a doctor and then have regular

medical check-ups to ensure medical problems

are not being caused or worsened from use.

Pregnant women or people who have impaired

blood circulation to the hand, past hand injuries,

nervous system disorders, diabetes, or Raynaud’s

Disease should not use this appliance. If you

feel any symptoms related to vibration (such as

tingling, numbness, and white or blue fingers),

seek medical advice as soon as possible.

2. Do not smoke during use. Nicotine reduces

the blood supply to the hands and fingers,

increasing the risk of vibration-related injury.

3. Wear suitable gloves to reduce the vibration

effects on the user.

4. Use appliances with the lowest vibration when

there is a choice between different processes.

5. Include vibration-free periods each day of work.

6. Grip appliance as lightly as possible

(while still keeping safe control of it).

Let the appliance do the work.

7. To reduce vibration, maintain the appliance

as explained in this manual. If any abnormal

vibration occurs, stop use immediately.

General Safety

1. Stop working when you feel tired or exhausted.

Make regular breaks to rest.

2. Keep all parts of the body away from saw chain.

Do not remove cut material or hold material to

be cut when saw chain is moving. Make sure the

switch is off when clearing jammed material.

3. Hold Pole Saw by insulated gripping surfaces

only, because the saw chain may contact

hidden wiring or its own cord. Saw chains

contacting a “live” wire may make exposed

metal parts of the garden power tool “live” and

could give the operator an electric shock.

4. Keep power cord away from cutting area.

During operation the power cord may be hidden in

shrubs and can be accidentally cut by the blade.

5. Before use, make sure the saw chain

is not contacting anything.

6. Hold Pole Saw with both hands on the handle.

7. Do not operate Pole Saw from within a tree.

Operation of tool while up in a tree

may result in personal injury.

8. Keep proper footing and operate the garden

power tool only when standing on fixed,

secure and level surface. Slippery or unstable

surfaces such as ladders may cause a loss of

balance or control of the garden power tool.

9. When cutting a limb that is under tension, be

alert for spring back. When the tension in the

wood fibers is released, the limb may strike the

operator and/or throw the tool out of control.

10. Do not use for bore cutting, felling or bucking.

11. Keep bystanders and other workers at

least 50 feet from the work area.

12. Do not operate within 50 feet of electrical lines.

13. Use extreme caution when cutting brush

and saplings. The slender material may catch

the saw chain and be whipped around.

14. Carry Pole Saw with tool switched off and

away from your body. Proper handling of

the Pole Saw will reduce the likelihood of

accidental contact with the moving saw chain.