E

n

v

i

r

o

n

m

e

n

t

a

l

l

y

F

r

i

e

n

d

l

y

T

e

c

h

n

o

l

o

g

y

Page 1

Contents

General .....................................................................................2

Manufacturer ................................................................................................................ 2

Application ................................................................................................................... 2

Correct Application ...................................................................................................... 2

Main Machine Parts ...................................................................................................... 3

Description of Labels .................................................................................................... 4

Operating the Circular Saw ........................................................5

General Safety Regulations ............................................................................................ 5

Start-up ......................................................................................................................... 5

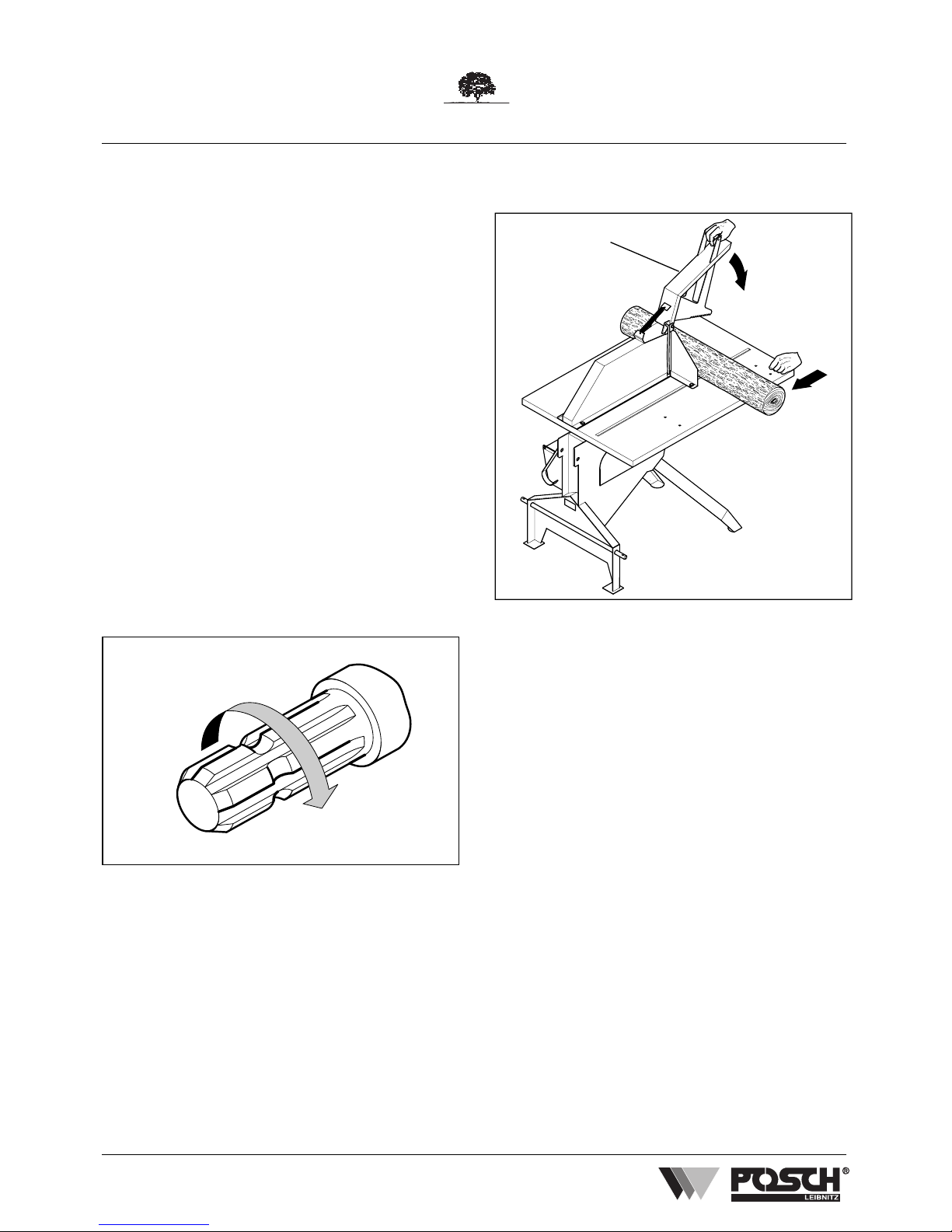

Longitudinal cutting ..................................................................................................... 7

Saw Blade Change ......................................................................................................... 9

Transportation ............................................................................................................ 10

Additional Equipment ................................................................................................ 10

Servicing .................................................................................11

General Safety Regulations .......................................................................................... 11

Lubrication ................................................................................................................. 11

Sharpening of Saw Blade ............................................................................................. 11

Setting of Saw Blade ................................................................................................... 11

Additional maintenance information ........................................................................... 12

V-belt Change and Tensioning ................................................................................... 12

Fault Remedy ..........................................................................14

Specification ............................................................................15

Conformity Declaration ...........................................................16