ODP 200 Technical Manual

3

1. eneral Specifications

1.1 Printing Specifications

1) Printing method: Thermal line printing

2) Dot density: 180dpi x 180dpi

203dpi x 180dpi

3) Printing direction: Unidirectional with friction feed

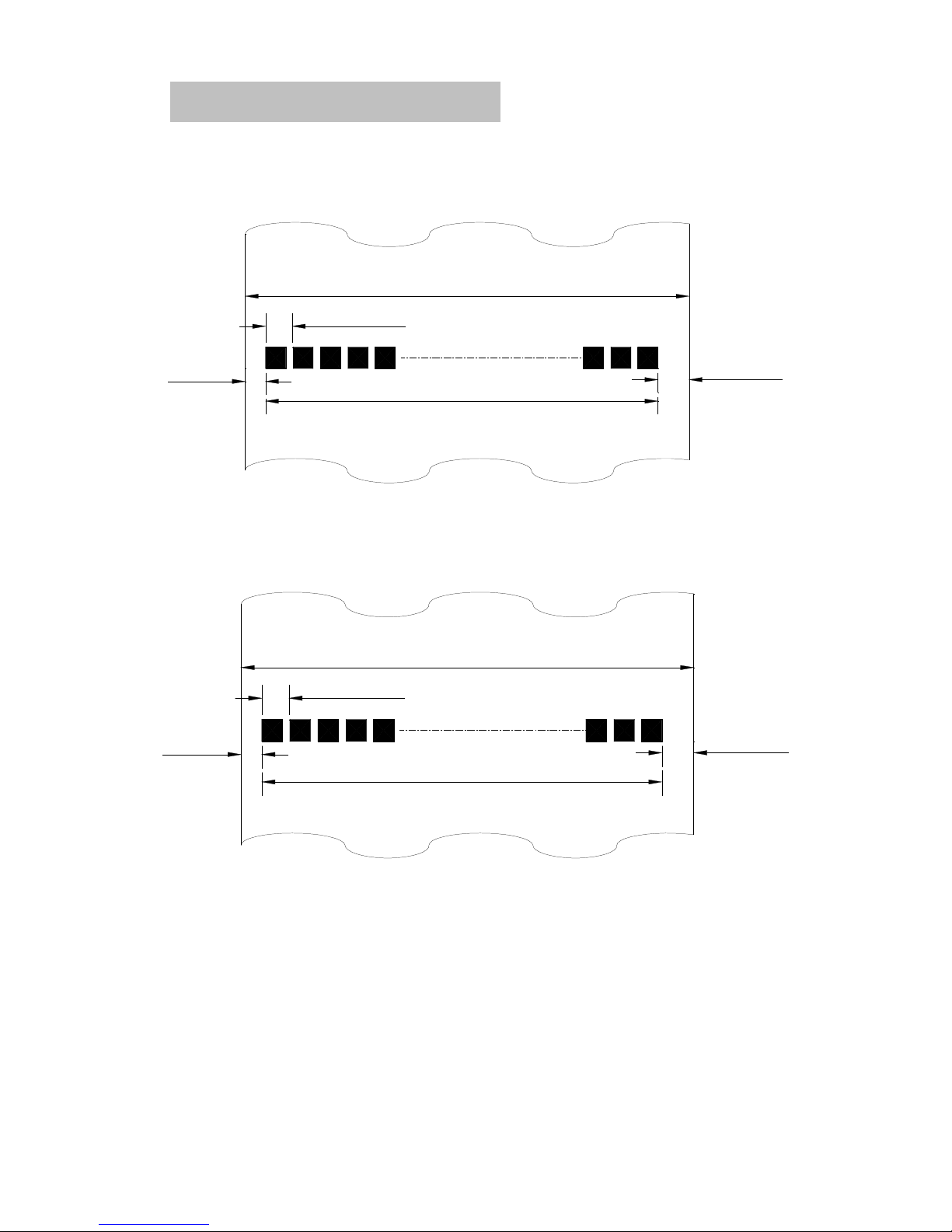

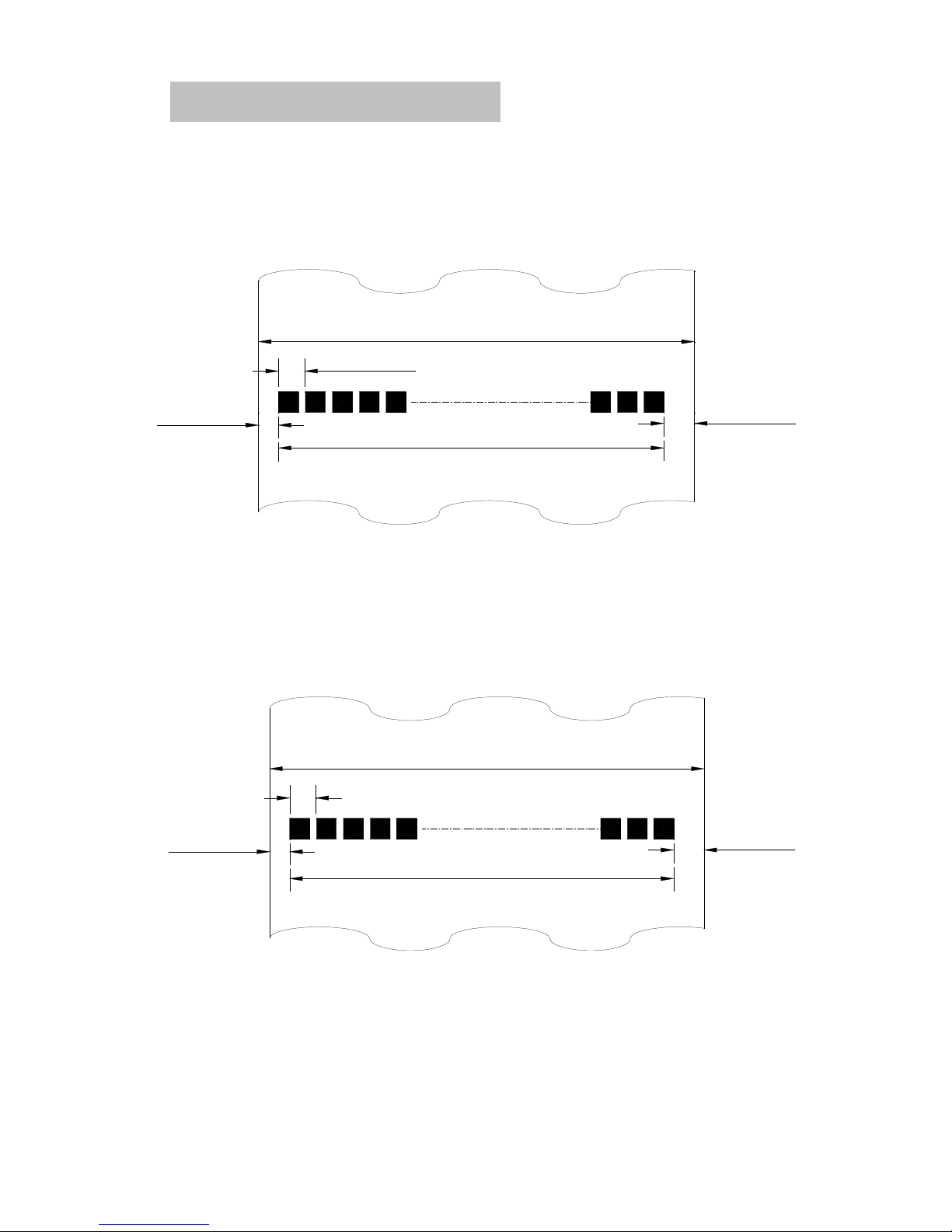

4) Printing width: 72mm(2.83"), 576 dot positions (203dpi)

72.2mm(2.84"), 512 dot positions (180dpi)

80mm(3.15"), 640 dot positions (203dpi)

5) Characters per line(default): Font A: 42

Font B: 56

6) Printing speed: High speed mode:

35.5lines/second maximum

(1/6inch feed) (at 24V, 20℃)

Approximately 150mm/sec maximum

(approximately 5.9inchs/sec maximum)

☞ NOTE: Speeds are switched depending on the applied voltage to the printer and head temperature

conditions automatically.

☞ NOTE: There may e variations in printing after switching the mode of the printing speed. To prevent this

for logo printing with ESC* command, using a downloaded it image is recommended. Change in printing

speed does not occur during down loaded it image printing.

7) Line spacing (default): 1/6 inch (4.23mm)

Programma le y control command.