7

LIMITED WARRANTY

POSline warrants to the original purchaser for a period of 12 months from the

date of invoice that this product is in good working order and free from defects in

material and workmanship under normal use and service. POSline’s obligation

under this warranty is limited to, at its option, replacing, repairing, or giving credit

for any product which has, within the warranty period, been returned to the factory

of origin, transportation charges and insurance prepaid, and which is, after ex-

amination, disclosed to POSline’s satisfaction to be thus defective. The expense

of removal and reinstallation of any item or items of equipment is not included

in this warranty. No person, firm, or corporation is authorized to assume for POS

line any other liabilities in connection with the sales of any product. In no event

shall POSline be liable for any special, incidental or consequential damages to

Purchaser or any third party caused by any defective item of equipment, whether

that defect is warranted against or not. Purchaser’s sole and exclusive remedy

for defective equipment, which does not conform to the requirements of sales, is

to have such equipment replaced or repaired by POSline. For limited warranty

service during the warranty period, please contact POSline to obtain a Return

Material Authorization (RMA) number & instructions for returning the product.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF MER-

CHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. THERE ARE

NO OTHER WARRANTIES OR GUARANTEES, EXPRESS OR IMPLIED,

OTHER THAN THOSE HEREIN STATED. THIS PRODUCT IS SOLD AS

IS. IN NO EVENT SHALL POSline BE LIABLE FOR CLAIMS BASED

UPON BREACH OF EXPRESS OR IMPLIED WARRANTY OF NEGLI-

GENCE OF ANY OTHER DAMAGES WHETHER DIRECT, IMMEDIATE,

FORESEEABLE, CONSEQUENTIAL OR SPECIAL OR FOR ANY EXPENSE

INCURRED BY REASON OF THE USE OR MISUSE, SALE OR FABRICA-

TIONS OF PRODUCTS WHICH DO NOT CONFORM TO THE TERMS AND

CONDITIONS OF THE CONTRACT.

The information contained herein is provided to the user as a convenience. While

every effort has been made to ensure accuracy, POSline assumes no responsibil -

ity, for its use, nor for any infringements or patents or other rights of third parties

that may result from its use. POSline is not responsible for damages that might

occur because of errors or omissions, including any loss of profit or other com-

mercial damage. The specifications described herein were current at the time of

publication, but are subject to change at any time without prior notice.

7

LIMITED WARRANTY

POSline warrants to the original purchaser for a period of 12 months from the

date of invoice that this product is in good working order and free from defects in

material and workmanship under normal use and service. POSline’s obligation

under this warranty is limited to, at its option, replacing, repairing, or giving credit

for any product which has, within the warranty period, been returned to the factory

of origin, transportation charges and insurance prepaid, and which is, after ex-

amination, disclosed to POSline’s satisfaction to be thus defective. The expense

of removal and reinstallation of any item or items of equipment is not included

in this warranty. No person, firm, or corporation is authorized to assume for ID

TECH any other liabilities in connection with the sales of any product. In no event

shall POSline be liable for any special, incidental or consequential damages to

Purchaser or any third party caused by any defective item of equipment, whether

that defect is warranted against or not. Purchaser’s sole and exclusive remedy

for defective equipment, which does not conform to the requirements of sales, is

to have such equipment replaced or repaired by POSline. For limited warranty

service during the warranty period, please contact POSline to obtain a Return

Material Authorization (RMA) number & instructions for returning the product.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF MER-

CHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. THERE ARE

NO OTHER WARRANTIES OR GUARANTEES, EXPRESS OR IMPLIED,

OTHER THAN THOSE HEREIN STATED. THIS PRODUCT IS SOLD AS

IS. IN NO EVENT SHALL POSline BE LIABLE FOR CLAIMS BASED

UPON BREACH OF EXPRESS OR IMPLIED WARRANTY OF NEGLI-

GENCE OF ANY OTHER DAMAGES WHETHER DIRECT, IMMEDIATE,

FORESEEABLE, CONSEQUENTIAL OR SPECIAL OR FOR ANY EXPENSE

INCURRED BY REASON OF THE USE OR MISUSE, SALE OR FABRICA-

TIONS OF PRODUCTS WHICH DO NOT CONFORM TO THE TERMS AND

CONDITIONS OF THE CONTRACT.

The information contained herein is provided to the user as a convenience. While

every effort has been made to ensure accuracy, POSline assumes no responsibil -

ity, for its use, nor for any infringements or patents or other rights of third parties

that may result from its use. POSline is not responsible for damages that might

occur because of errors or omissions, including any loss of profit or other com-

mercial damage. The specifications described herein were current at the time of

publication, but are subject to change at any time without prior notice.

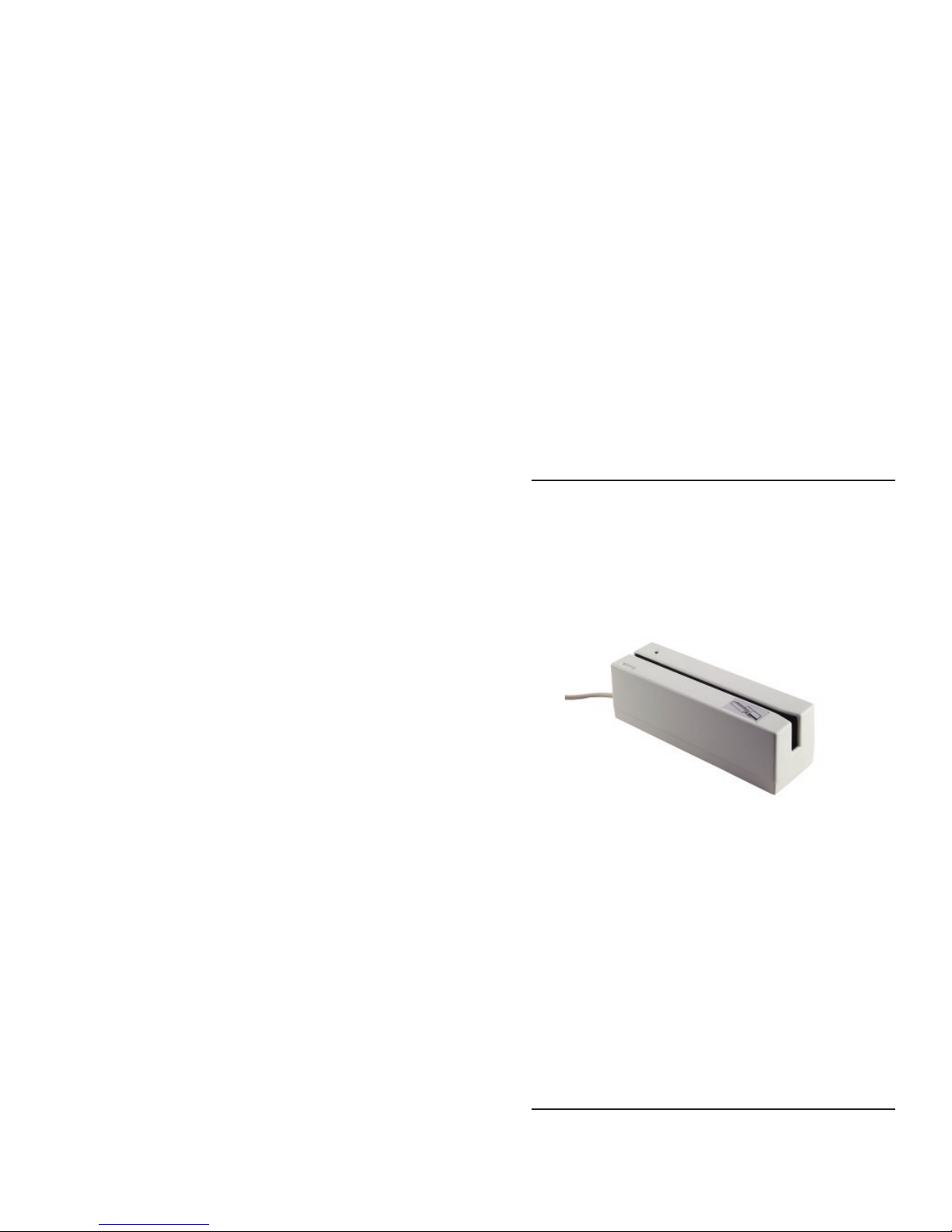

MAINTENANCE

The GM2250 requires card slot cleaning on a regular interval. The interval

is approximate and should be after every 50,000 card swipes. Regular

cleaning insures oils and debris do not accumulate on the operating

components.

Over time, operation can cause a film to collect on the heads and other

surfaces. This film should be removed using “cleaning cards”. These are

available from magnetic stripe cleaning card sources. Cleaning cards are

about the same size as an ID1 (credit card) and have an absorbent surface

on one or both sides. The absorbent surface has an alcohol solvent that

should remove any film. The absorbent surface should be damp; the

surface should not be saturated.

Swipe the card five to ten times with the solvent side of the card toward the

read and write heads and then again five to ten times with the solvent side

opposite the heads.

The cleaning cards may not remove all the debris. In the case of debris

such as dust and card particles in the slot, use an aerosol can product

having clean compressed air. The clean air can be used to blow debris

from the slot. Direct the stream of air at a low angle into the slot and run

the nozzle along the slot. Direct the air in the direction of the card travel

and then in the opposite direction. Inspect the slot by looking down its

length with a good backlight to see if all debris are removed.

The metal housing can be cleaned with a mild detergent applied to a soft

cloth that is rung almost dry. Detergent should not be allowed to enter the

card slot.

Warning: There are no serviceable components inside the GM2250.

Opening the GM2250 voids the warranty. Tampering with the write head

or tachometer assemblies may change the GM2250 calibrations for ISO

standards operation.

MAINTENANCE

The GM2250 requires card slot cleaning on a regular interval. The interval

is approximate and should be after every 50,000 card swipes. Regular

cleaning insures oils and debris do not accumulate on the operating

components.

Over time, operation can cause a film to collect on the heads and other

surfaces. This film should be removed using “cleaning cards”. These are

available from magnetic stripe cleaning card sources. Cleaning cards are

about the same size as an ID1 (credit card) and have an absorbent surface

on one or both sides. The absorbent surface has an alcohol solvent that

should remove any film. The absorbent surface should be damp; the

surface should not be saturated.

Swipe the card five to ten times with the solvent side of the card toward the

read and write heads and then again five to ten times with the solvent side

opposite the heads.

The cleaning cards may not remove all the debris. In the case of debris

such as dust and card particles in the slot, use an aerosol can product

having clean compressed air. The clean air can be used to blow debris

from the slot. Direct the stream of air at a low angle into the slot and run

the nozzle along the slot. Direct the air in the direction of the card travel

and then in the opposite direction. Inspect the slot by looking down its

length with a good backlight to see if all debris are removed.

The metal housing can be cleaned with a mild detergent applied to a soft

cloth that is rung almost dry. Detergent should not be allowed to enter the

card slot.

Warning: There are no serviceable components inside the GM2250.

Opening the GM2250 voids the warranty. Tampering with the write head

or tachometer assemblies may change the GM2250 calibrations for ISO

standards operation.