Supplied By www.heating spares.co Tel. 0161 620 6677

INTRODUCTION

The information given on this card will help you to obtain the

maximum comfort from your boiler with the minimum trouble and

cost. Your boiler is fully automatic in operation and requires very

little attention apart from setting the thermostat.

Regular skilled servicing is required to maintain the safe and

efficient operation of your boiler throughout its long working life.

Further information on this subject is given at a later stage.

ELECTRICITY SUPPLY

WARNING: THIS APPLIANCE MUST BE EARTHED

Connection shall be made to a 240V-50 Hz supply. The appliance

must be protected by a 3 amp fuse if a 13 amp (B51363) plug is

used or if any other type of plug is used by a 5 amp fuse in the

circuit.

TO CONNECT A PLUG

As the colour of the wires in the mains lead of the appliance may

not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:-

The wire which is coloured green-and-yellow must be connected to

the terminal in the plug which is marked with the letter E or by the

earth symbol or coloured green or green-and-yellow.

The wire which is coloured blue must be connected to the terminal

which is marked with the letter N or coloured black.

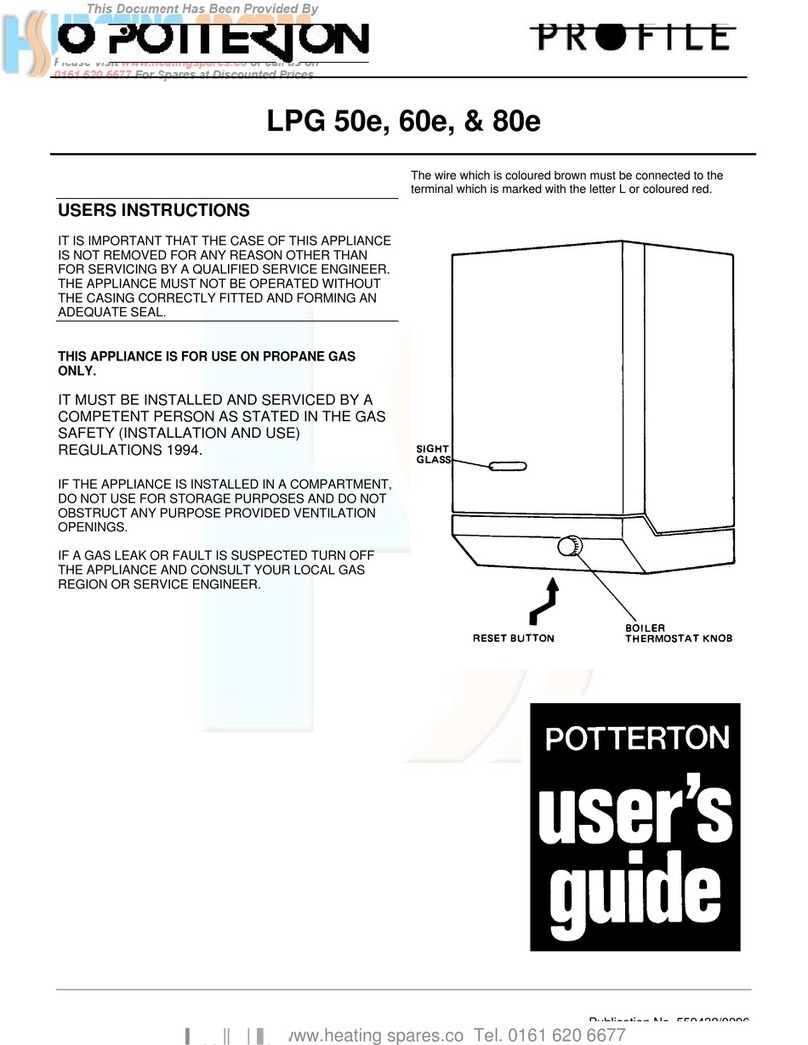

The wire which is coloured brown must be connected to the

terminal which is marked with the letter L or coloured red.

SAFETY

The boiler should have the following minimum clearances for

Safety and Maintenance, 610mm (2ft) at the front of the boiler,

5mm (3116in) each side, 100mm (4in) at the bottom, 50mm (2in)

at the top.

Flammable materials must not be stored in close proximity to the

boiler.

Ensure that the flue terminal outside the house, does not become

obstructed, particularly by foliage.

THE BOILER THERMOSTAT

The boiler thermostat enables you to control the temperature of

the water as it leaves the boiler and is also used for turning the

boiler on and off. The thermostat knob can be set to 0 (OFF),

1,2,3,4,5 or Max. The graduations 1 to Max. correspond

approximately to a temperature range of 55C to 82 C (130F -

180F).

During the summer months, when the boiler is only being used to

supply stored domestic hot water and there is no independent hot

water temperature control, the thermostat can be set to position 1

or 2 which will probably be hot enough for bathing or washing up

requirements. For washing clothes, a higher setting may be

necessary.

In winter weather, when central heating is required, the thermostat

knob can be turned up higher but it must be remembered that

unless the temperature of the water in the domestic hot water

cylinder is independently controlled, the stored hot water could be

at a temperature that could scald, i.e. about 82C (180°F).

OTHER CONTROLS

A Potterton Electronic Programmer or other type of clock may

have been fitted in your system, together with room and/or cylinder

thermostats. Full instructions on the use of these controls should

be supplied with them.

TO LIGHT

1. Ensure that the boiler thermostat knob is at ‘0’ (fully anti-

clockwise).

2. Switch ‘ON’ the main electricity supply.

3. Ensure the electronic programmer or other time control, if

fitted, is in an ‘ON’ period (refer to time control literature).

4. Ensure that any room and/or cylinder thermostats are at a

high temperature setting.

Proceed as follows:— Turn the boiler thermostat on and to the

required setting. After a short period, the boiler will light: the main

burner can be seen through the sight glass on the front of the

boiler. Set the time control and any thermostats, where fitted, to

their desired settings.

NOTE:- When the boiler is first lit, there may be a slight smell. This

will disappear with use.

TO SHUT THE BOILER OFF

Turn the boiler thermostat knob to ‘0’, or switch the external

programmer to the ‘OFF’ position. To relight the boiler, simply turn

the boiler thermostat ‘ON’ or switch tile programmer to the ‘ON’

position.

FOR LONGER SHUT DOWN PERIODS

Turn the boiler thermostat to ‘0’, isolate the electrical supply at the

isolating switch, or pull the plug out of its socket.

NOTE:

If the system is fitted with a low limit thermostat and protection of

the system is required during cold weather, all that is required is

for the programmer to be turned to the ‘OFF’ position. This will

allow the boiler to cycle if the temperature within the house

becomes too low.

IMPORTANT

Gas and electricity are required to operate your boiler. Its

performance will not be affected by normal variation in gas or

electricity supply, but a gas or electricity failure will put the boiler

out of operation. It will automatically re-start when the supply is

restored, provided that the time clock and/or thermostats are in an

‘ON’ position.

In the event of your boiler not working, there are several checks

you should carry out before calling in a service engineer, as this

could save you unnecessary expense.

1Check that the gas, electricity and water are all turned on at

the main supply.

2. Check that the time control, if fitted, is in an ‘ON’ period.