EQUIPMENT

IDENTIFICATION

-

The

unit's

identification

number

(either

a

Specifi-

cation

number,

or

an Assembly number), model, and

serial

number

usually

appear

•)n

a nameplate

attached

to

its

control

panel.

SAFETY

WAR.'iiNGS

OWNER'S

MANUAL

NO.

201006-00lA

Power

Drive

II

Semiautomatic

Solid-State

Control

Wire

Feeder

This

manual

covers

units

displaying

any

one

of

the

following

specification

num-

bers:

601104-001

2-Roll

Drive,

60-600

IPM

Other

documentation

to

cover

components

used

in

this

raodel

wire

feeder:

Control

oox 601104-00SA

Feedhead Assembly 601104-006

Base 601104-007

Wire Spool

Support

Assembly 601106-001.

Issued:

Aug

7/85

Taeie of Contents

Page

MAINTENANCE

CHAPTER

l -

INSTRUCTIONS

1

1

l

1

1

2

2

2

2

2

CHAPTER

2 -

GOMPONENTS

SPECIFIC

!0

wiRE

FEEDER

MODEL

POWER

DRIVE

ti

RECEIPT

OF

EQUIPMENT

DESCRIPTION

OF

EQUIPMENT

General

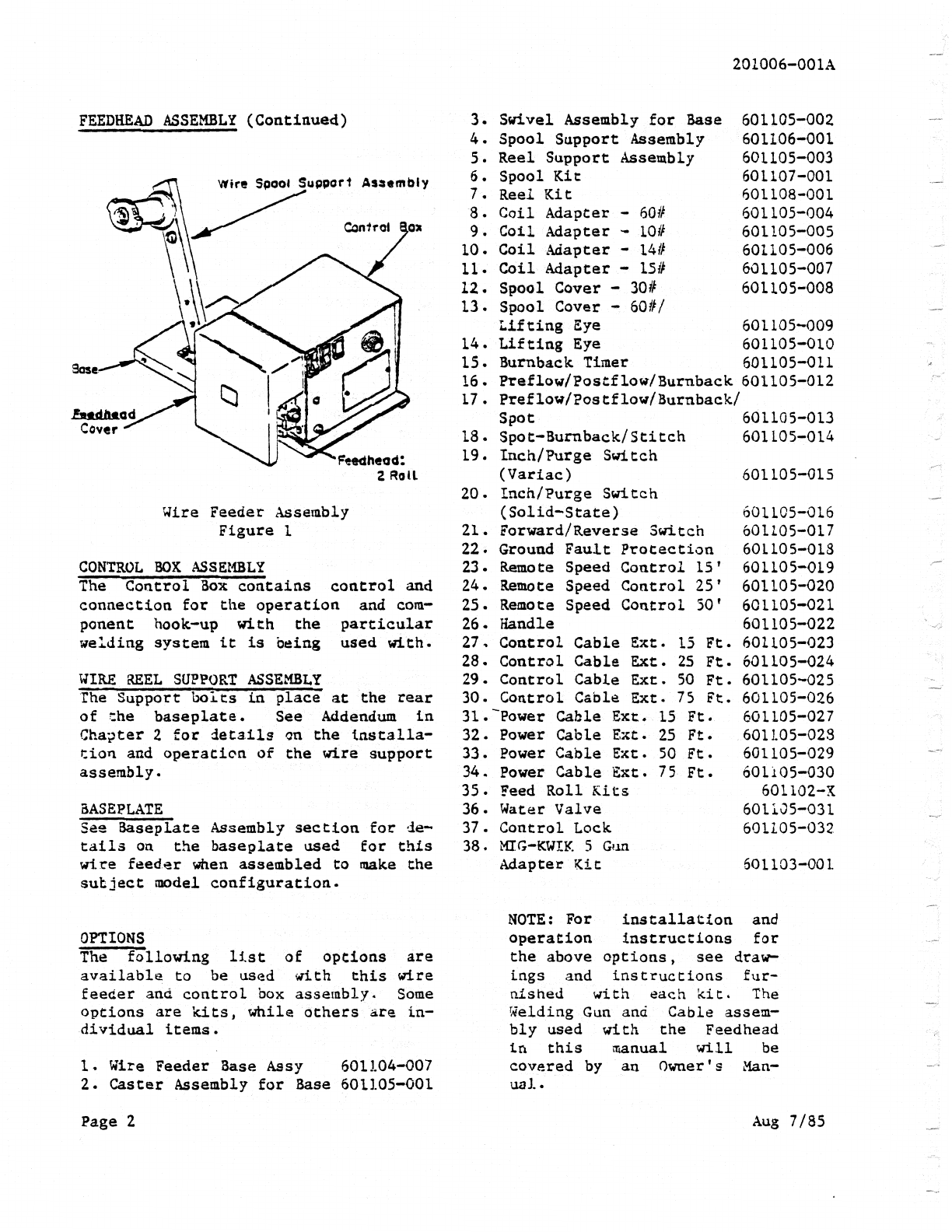

Feedhead Assembly

Control

Box

Assembly

Wire Reel

Support

Assemb2.y

Baseplate

Options

IN'STALLATION

OPERATION

Prewelding

Checks

Weldia.g

3

3

3

Control

Box

Feedhead Assembly

Baseplate

~Jire

Spool Support Asst:!mbl;•

CHAPTER

3 -

PARTS

LISTS

CHAPTER

4 -

DIAGRAMS

WARRANTY

Page

3