Powell PowlVac 01.4IB.51051C User manual

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

(51897G11)

For Use With PowlVac®CDR 5kV & 15kV Circuit Breakers

Powered by Safety®

Powered by Safety®

01.4IB.51051C

Signal Words

As stated in ANSI Z535.4-2007, the signal word is

a word that calls attention to the safety sign and

designates a degree or level of hazard seriousness.

The signal words for product safety signs are

“Danger”, “Warning”, “Caution” and "Notice".

These words are defined as:

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

!

DANGER

!

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

CAUTION

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

CAUTION, used without the safety alert

symbol, is used to address practices not

related to personal injury.

CAUTION

NOTICE

NOTICE is used to address practices not related

to personal injury.

Qualified Person

For the purposes of this manual, a qualified

person, as stated in NFPA 70E®, is one who has

skills and knowledge related to the construction

and operation of the electrical equipment and

installations and has received safety training to

recognize and avoid the hazards involved. In

addition to the above qualifications, one must also

be:

1. trained and authorized to energize,

deenergize, clear, ground, and tag circuits

and equipment in accordance with

established safety practices.

2. trained in the proper care and use of

personal protective equipment (PPE)

such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc.,

in accordance with established safety

practices.

3. trained in rendering first aid if necessary.

Powered by Safety®

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

01.4IB.51051C

This page is intentionally left blank.

Powered by Safety®i

01.4IB.51051C

Ch 1 General Information ................................................................................................1

A. Scope ...............................................................................................................................................................2

B. purpoSe ............................................................................................................................................................2

c. InStructIon BulletInS AvAIlABle electronIcAlly ....................................................................................................2

Ch 2 Safety .......................................................................................................................3

A. SAfe Work condItIon .........................................................................................................................................3

B. SAfety GuIdelIneS ...............................................................................................................................................3

c. GenerAl ............................................................................................................................................................3

d. SAfety lABelS ....................................................................................................................................................4

Ch 3 Equipment Description ............................................................................................5

A. GenerAl ............................................................................................................................................................5

B. Motor control Box ..........................................................................................................................................5

c. reMote rAckInG devIce .......................................................................................................................................5

d. reMote rAckInG operAtIon .................................................................................................................................6

Ch 4 Installation ...............................................................................................................9

A. receIvInG ...........................................................................................................................................................9

B. HAndlInG ..........................................................................................................................................................9

c. StorAGe ............................................................................................................................................................9

d. prepArAtIon ................................................................................................................................................... 10

1) Support Lock Pin, Support Hanger, and Installation Template ..................................................................................10

2) Testing and Inspection .........................................................................................................................................................10

3) Remote Racking Device Inspection ...................................................................................................................................10

Ch 5 Operation ...............................................................................................................11

A. InStAllInG And operAtInG tHe reMote rAckInG devIce for rAckInG In................................................................... 11

1) Installing the Remote Racking Device for Circuit Breaker Racking In .......................................................................11

2) Performing Circuit Breaker Racking In .............................................................................................................................14

B. InStAllInG And operAtInG tHe reMote rAckInG devIce for rAckInG out ................................................................ 15

1) Installing the Remote Racking Device for Circuit Breaker Racking Out ...................................................................15

2) Performing Circuit Breaker Racking Out ..........................................................................................................................16

c. unInStAllInG tHe reMote rAckInG devIce ........................................................................................................... 17

Ch 6 Maintenance ..........................................................................................................18

A. GenerAl ......................................................................................................................................................... 18

B. InSpectIon And cleAnInG .................................................................................................................................. 18

c. luBrIcAtIon .................................................................................................................................................... 18

Ch 7 Recommended Renewal Parts ...............................................................................19

A. orderInG InStructIonS ..................................................................................................................................... 19

Contents

Powered by Safety®

ii

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

Tables

Table A Renewal Parts .....................................................................................................19

Figures

Figure 1 Remote Racking Device Assembly .................................................................5

Figure 2 Motor Control Box ..........................................................................................5

Figure 3 Remote Racking Device (Receptacle Side) .....................................................6

Figure 4 Remote Racking Device (Lock Pin Side) .........................................................6

Figure 5 Switchgear Compartment Door ....................................................................7

Figure 6 Circuit Breaker Inside Switchgear Compartment ..........................................8

Figure 7 Insert the Motor Control Box Cable Plug .....................................................12

Figure 8 Unlatch the Racking Device Spring Lock Pin ...............................................13

Figure 9 Insert the Drive Socket into the Racking Shaft Access Opening .................13

Figure 10 Push Down the Support Latch .....................................................................13

Figure 11 Turn the Spring Lock Pin to Secure the Racking Device

on the Support Lock Pin ...............................................................................13

Figure 12 Lift the Slide Assembly and Engage the Racking Device

Support Hanger ...........................................................................................14

Figure 13 Turn the Adjustment Knob to Engage the Racking Shaft

with the Drive Socket ...................................................................................14

Figure 14 Operate Motor Control Box .........................................................................15

Powered by Safety®1

General Information

01.4IB.51051C

Ch 1 General Information

!

WARNING

The equipment described in this document may contain high voltages and currents which can

cause death or serious injury.

The equipment is designed for use, installation, and maintenance by knowledgeable users of such

equipment having experience and training in the field of high voltage electricity. This document and all

other documentation shall be fully read, understood, and all warnings and cautions shall be abided by. If

there are any discrepancies or questions, the user shall contact Powell immediately at 1.800.480.7273.

!

WARNING

Prior to adjustments, servicing, maintenance, or any act requiring the operator to make physical

contact with the equipment, the power source must be disconnected and the equipment grounded.

Failure to do so may result in death or serious injury.

NOTICE

The information in this instruction bulletin is not intended to explain all details or variations of the

Powell equipment, nor to provide for every possible contingency or hazard to be met in connection

with installation, testing, operation, and maintenance of the equipment. For additional

information and instructions for particular problems, which are not presented sufficiently for the

user’s purposes, contact Powell at 1.800.480.7273.

Powell reserves the right to discontinue and to change specifications at any time without incurring

any obligation to incorporate new features in products previously sold.

NOTICE

Powered by Safety®

2General Information

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

A. Scope

The information in this instruction bulletin

describes the following PowlVac®Remote

Racking Device and components for use

with PowlVac CDR 5kV & 15kV vacuum circuit

breakers:

• 51897G11 - Remote Racking Device and

Motor Control Box (complete assembly)

• 51899G10 - Remote Racking Device

• 51895G01 - Motor Control Box

B. purpoSe

The information in this instruction bulletin is

intended to provide information required to

properly operate and maintain the

PowlVac Remote Racking Device and

components described in Ch 1 General

Information, A. Scope.

This instruction bulletin provides:

1. Safety guidelines

2. General descriptions of the operation

and maintenance of the PowlVac Remote

Racking Device and components

3. Instructions for installation

4. Illustrations, photographs, and description

of the equipment described in

Ch 1 General Information, A. Scope

The illustrations and photos in this document

are provided as general information to aid in

showing component locations only.

All illustrations and photos are shown using

deenergized equipment.

Follow the appropriate safety precautions

while handling any of the equipment. Failure

to do so may result in death or serious injury.

!

WARNING

To the extent required, the products described

herein meet the applicable ANSI, IEEE, and

NEMA Standards; however, no such assurance

is given with respect to local codes and

ordinances which may vary greatly.

c. InStructIon BulletInS AvAIlABle electronIcAlly

Changes to the instruction bulletin may be

implemented at any time and without notice.

Go to powellind.com to ensure use of the current

instruction bulletin for Powell equipment.

NOTICE

To contact the Powell Service Division call

1.800.480.7273 or 713.944.6900, or email

For specific questions or comments pertaining

to this instruction bulletin email

documents@powellind.com with the Instruction

Bulletin number in the subject line.

Powered by Safety®3

Safety

01.4IB.51051C

Ch 2 Safety

A. SAfe Work condItIon

The information in Section A is quoted from

NFPA 70E 2012 - Article 120, 120.1 Establishing an

Electrically Safe Work Condition.

120.1 Process of Achieving an Electrically Safe

Work Condition

1. Determine all possible sources of electrical

supply to the specific equipment. Check

applicable up-to-date drawings, diagrams,

and identification tags.

2. After properly interrupting the load current,

OPEN the disconnecting device(s) for each

source.

3. Wherever possible, visually verify that all

blades of the disconnecting devices are

fully OPEN or that drawout type circuit

breakers are withdrawn to the fully

disconnected position.

4. Apply lockout/tagout devices in accordance

with a documented and established policy.

5. Use an adequately rated voltage detector

to test each phase conductor or circuit part

to verify they are deenergized. Test each

phase conductor or circuit part both

phase-to-phase, and phase-to-ground.

Before and after each test, determine

that the voltage detector is operating

satisfactorily.

Informational Note: See ANSI/ISA-61010-1

(82.02.01)/UL 61010-1, Safety Requirements

for Electrical Equipment for Measurement,

Control, and Laboratory Use - Part 1: General

Requirements, for rating and design

requirements for voltage measurement

and test instruments intended for use on

electrical systems 1000 V and below.

6. Where the possibility of induced voltages

or stored electrical energy exists, ground

the phase conductors or circuit parts

before touching them. Where it could be

reasonably anticipated that the conductors

or circuit parts being deenergized

could contact other exposed energized

conductors or circuit parts, apply ground

connecting devices rated for the available

fault duty.

B. SAfety GuIdelIneS

Each user has the responsibility to instruct

and supervise all personnel associated with

usage, installation, operation, and maintenance

of this equipment on all safety procedures.

Furthermore, each user has the responsibility of

establishing a safety program for each type of

equipment encountered.

The safety rules in this instruction bulletin are

not intended to be a complete safety program.

The rules are intended to cover only some of the

important aspects of personnel safety related to

PowlVac® Remote Racking Device Assemblies.

c. GenerAl

1. Only supervised and qualified personnel

trained in the usage, installation, operation,

and maintenance of the circuit breaker shall

be allowed to work on this equipment. It

is mandatory that this instruction bulletin,

any supplements, and service advisories be

studied, understood, and followed.

2. Maintenance programs must be consistent

with both customer experience and

manufacturer’s recommendations,

including service advisories and instruction

bulletin(s). A well planned and executed

routine maintenance program is essential

for reliability and safety.

Powered by Safety®

4Safety

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

3. Service conditions and applications shall

also be considered in the development of

safety programs. Variables include ambient

temperature; humidity; actual continuous

current; thermal cycling; number of

operations; interrupting duty; and any

adverse local conditions including excessive

dust, ash, corrosive atmosphere, vermin

and insect infestations.

d. SAfety lABelS

Warning and Caution labels are located in

various places. Do NOT remove or deface any

of these warning/caution labels.

NOTICE

Powered by Safety®5

Equipment Description

01.4IB.51051C

Ch 3 Equipment Description

A. GenerAl

The PowlVac® Remote Racking Device

Assembly is an accessory which enables

circuit breakers to be racked into and out of

switchgear from a distance. The assembly

consists of a motor control box (Figure 1, a) and

remote racking device (Figure 1, b).

Figure 1 Remote Racking Device Assembly

a. Motor Control Box

b. Remote Racking Device

a

b

B. Motor control Box

The motor control box (Figure 2) supplies power

enables the selection of operating modes for

the remote racking device. The motor control

box has a 50 foot long cord (Figure 2, b) with a

plug that is inserted into the remote racking

device twist lock receptacle (Figure 3, f). The

length of cord enables the user to move to a

safe distance from the circuit breaker during

racking in and racking out procedures. The

motor control box power supply cord is

6’ long and plugs into a 110VAC 15A outlet

(Figure 2, a).

Figure 2 Motor Control Box

a. Power Supply Cord

b. Control Box Cord

c. “IN” Indicator Light

d. “OUT” Indicator Light

e. Power Switch

f. Push Button

g. IN/OUT Selector Switch

ab

ef

g

cd

c. reMote rAckInG devIce

The remote racking device (Figure 1, b) installs

on the switchgear compartment door. The

racking device support latch (Figure 3, a)

attaches to a lock pin (Figure 10, b) installed

on the compartment door. The racking

device drive socket (Figure 3, e) engages the

circuit breaker racking mechanism through

the compartment door racking shaft access

opening (Figure 5, d). After the racking device

is installed, the adjustment knob (Figure 4, b)

must be turned until the racking device drive

socket engages with the circuit breaker racking

shaft.

When the racking device is connected to the

motor control box and energized, the drive

socket operates the circuit breaker racking

shaft (Figure 6, b) during racking in and racking

out procedures.

Powered by Safety®

6Equipment Description

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

Figure 3 Remote Racking Device (Receptacle

Side)

a. Support Latch

b. Recessed Bumpers

c. Handle

d. Drive Shaft and Spring

e. Drive Socket

f. Twist-Lock Receptacle

g. Front Plate

h. Slide Assembly

a

bc

d

ef

g

h

Figure 4 Remote Racking Device (Lock Pin

Side)

b

a

a. Latch Pin Lock

b. Adjustment Knob

d. reMote rAckInG operAtIon

Do NOT work on an energized circuit breaker.

Follow circuit breaker safety guidelines and

operating instructions provided in the specific

circuit breaker instruction bulletin.

!

WARNING

Attaching and operating the remote racking

device can be accomplished by one person.

When circuit breaker racking is required,

the remote racking device engages the

circuit breaker racking shaft through the

compartment door racking shaft access

opening (Figure 5, d). The racking device is

operated by the motor control box.

Powered by Safety®7

Equipment Description

01.4IB.51051C

Figure 5 Switchgear Compartment Door

a

c

b

d

a. Compartment Door

b. Support Lock Pin

c. Circuit Breaker Racking Shaft Access Cover (Teardrop)

d. Circuit Breaker Racking Shaft

Powered by Safety®

8Equipment Description

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

Figure 6 Circuit Breaker Inside Switchgear

Compartment

a. Circuit Breaker in Compartment

b. Circuit Breaker Racking Shaft

c. Secondary Disconnect Receptacle

d. Anti-Rollout Latch

e. Compartment Floor

a

e

c

d

b

Powered by Safety®9

Installation

01.4IB.51051C

Ch 4 Installation

A. receIvInG

Upon receipt, remove any shipping material

and inspect the remote racking device for

damage that may have occurred during

shipment. If damage is found or suspected, file

all claims immediately with the transportation

company and notify the nearest Powell

representative. Check the equipment received

against the shipping documents to ensure

receipt of the complete shipment.

B. HAndlInG

The remote racking device weighs 20 lbs.

and the motor control box assembly weighs

5 lbs. The preferred method for moving the

remote racking device and motor control box

is to place them securely on a hand operated

shop cart. When handling the remote racking

device, personnel should securely grasp the

device by its handle during movement and

installation to avoid possible personal injury or

damage to the remote racking device. Avoid

dropping or hitting the remote racking device

with hard objects.

Protect the motor control box and the remote

racking device from moisture. Failure to do so

may cause damage to the equipment.

!

CAUTION

Do NOT handle or carry the remote racking

device by the power cords. Damage to the

power connections may cause an electrical

short. The power cords should be inspected

for any signs of damage before each use.

!

CAUTION

Do not attempt to work with a remote racking

device and motor control box if the electrical

cords are damaged or if the devices have

become wet. Using electrical equipment in

or around water may cause electric shock

and may result in injury to personnel and/or

damage to equipment.

!

WARNING

c. StorAGe

The remote racking device and motor control

box are accessories that are not normally in

continuous service. These accessories should

be stored properly so that they will be available

when needed. The following precautions

must be taken to ensure proper storage of the

remote racking device and motor control box.

1. DO NOT store the remote racking device

and motor control box in the switchgear

compartment.

2. The remote racking device and motor

control box should be carefully protected

against condensation. The device should

be stored in a warm, dry room of moderate

temperature, such as 40 - 100°F. Since the

remote racking device and motor control

box are to be energized during use, they

must be kept completely dry to avoid

accidental electric shock to personnel

and/or damage to the equipment.

3. Store the remote racking device and motor

control box in a clean location, free from

corrosive gasses or fumes. Particular care

should be taken to protect the devices

from moisture and cement dust, as this

combination has a very corrosive effect on

many parts.

Powered by Safety®

10 Installation

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

4. Apply A-grease on the drive shaft, under

the spring, to prevent corrosion and help

ensure proper operation.

5. If the remote racking device and motor

control box are stored for any length of

time, they should be inspected periodically

for corrosion and to ensure they are in good

mechanical condition.

d. prepArAtIon

Prior to using the Remote Racking Device,

refer to the Instruction Bulletin supplied with

the circuit breaker for complete instructions

on inserting and removing the circuit breaker

in to or out of the compartment.

CAUTION

1) Support Lock Pin, Support Hanger, and

Installation Template

Note: The circuit breaker must be removed

from service when the support lock

pin is installed.

The lock pin and support hanger must be

installed to support the remote racking

device on the compartment door.

A template for placing the support hanger

in the correct location is available. Refer to

Table A, Renewal Parts.

When installed, the racking device support

latch fastens onto the support lock pin, and

the slide assembly engages the support

hanger. The position of the racking device

enables the drive socket to engage the

circuit breaker racking shaft through the

access door to perform racking procedures.

To install the lock pin and support hanger,

follow directions accompanying the parts

order. For information on ordering the

support lock pin, support hanger, and

template, See Ch 7 Recommended Renewal

Parts.

2) Testing and Inspection

a. Electrical Operation Check

To pretest the equipment, insert the

50’ cord from the box into the racking

device locking receptacle. Then insert

the motor control box power supply

cord into a 110VAC 15A receptacle, and

operate the box on the racking in and

racking out settings while the device is

not installed on the circuit breaker or

compartment door.

3) Remote Racking Device Inspection

a. Inspect the remote racking device

for proper lubrication, signs of wear,

or damage. If plugs and wiring are

damaged, return the equipment to

Powell for repair.

b. Inspect the switchgear compartment

to ensure that it is clean and clear of

debris that might interfere with circuit

breaker racking and travel within the

compartment.

Powered by Safety®11

Operation

01.4IB.51051C

Ch 5 Operation

The instructions in this section are intended

to explain procedures for using the remote

racking device and the motor control box. For

circuit breaker handling, insertion, and removal

procedures, review the instruction bulletin

specific to the circuit breaker in use.

Do NOT work on an energized circuit breaker.

Follow circuit breaker safety guidelines and

operating instructions provided in the specific

circuit breaker instruction bulletin.

!

WARNING

A. InStAllInG And operAtInG tHe reMote rAckInG

devIce for rAckInG In

Before installing any circuit breaker into a

compartment, the user MUST verify that the

circuit breaker rating meets the metal-clad

switchgear rating.

!

CAUTION

This section describes procedures for installing

and operating the remote racking device for

racking IN. For racking OUT procedures, refer

to Ch 5 Operation, B. Installing and Operating the

Remote Racking Device for Racking Out.

1) Installing the Remote Racking Device for

Circuit Breaker Racking In

Prior to inserting the circuit breaker into the

circuit breaker compartment, ensure that the

control circuits are deenergized.

!

CAUTION

Prior to inserting the circuit breaker into the

circuit breaker compartment, ensure that the

circuit breaker is OPEN and the mechanism is

discharged.

!

CAUTION

1. Ensure the remote racking device

support lock pin (Figure 10, b) and the

support hanger (Figure 9, d) are installed

on the switchgear compartment door.

See Ch 4 Installation, D. Preparation,

1) Support Lock Pin, Support Hanger, and

Installation Template.

2. Ensure the switchgear compartment

control circuit is deenergized.

3. Move the circuit breaker to the

required switchgear location. Open the

compartment door and push the circuit

breaker into the compartment until the

anti-rollout latch (Figure 6, d) engages

the switchgear rollout stop block.

4. Insert the switchgear secondary

disconnect device into the circuit

breaker secondary disconnect

receptacle (Figure 6, c).

5a. For non-arc resistant switchgear,

perform the following steps:

• Assemble the racking mechanism

retainer assembly to the circuit

breaker compartment.

• Secure the racking drive shaft

extension in place by placing the

shaft retainer holder into the shaft

retainer anchor, then lock the

racking drive shaft extension in

place using the wing nut.

5b. For arc resistant switchgear, close and

latch the compartment door.

Powered by Safety®

12 Operation

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

6. On the compartment door, rotate the

teardrop shaped racking shaft access

cover (Figure 5, c) clockwise to access

the opening.

7. To prepare the remote racking device

for operation, insert the plug of the

motor control box cord into the remote

racking device twist-lock receptacle

(Figure 7). Turn the plug / turn

clockwise to lock the plug in

the receptacle.

8. Unlatch the racking device spring lock

pin (Figure 8).

9. Grasp the remote racking device by the

top handle with the drive socket toward

the circuit breaker (Figure 9, a). Insert

the drive socket into the racking shaft

access opening until the socket engages

the circuit breaker racking shaft. With

the drive socket in place, position the

racking device support latch

(Figure 10, a) onto the support lock pin

(Figure 10, b).

10. Push down the top of the racking device

support latch to close the latch

(Figure 10, a).

11. Turn the spring lock pin to the lock

position to secure the remote racking

device to the support lock pin

(Figure 11, a).

To avoid damage to equipment, and ensure

proper racking operation, the circuit breaker

racking mechanism must be engaged by the

racking socket before the remote racking

device is operated. For proper operation, the

racking device must be held securely by the

support lock pin and the hanger support.

CAUTION

12. With the racking device locked onto

the support lock pin, raise the racking

device slide assembly. Position

the racking device close to the

compartment door, and lower the slide

assembly to engage the racking device

support hanger (Figure 12).

13. With the racking device installed on the

compartment door, turn the adjustment

knob until it engages the drive socket

with the circuit breaker racking shaft

(Figure 13, a).

14. Physically move the motor control box

to a distant area to operate the remote

racking device.

The remote racking device is positioned

and ready to be energized for racking the

circuit breaker into the switchgear.

Figure 7 Insert the Motor Control Box Cable

Plug

a

b

a. Locking Receptacle

b. Motor Control Box Power Cable Plug

Powered by Safety®13

Operation

01.4IB.51051C

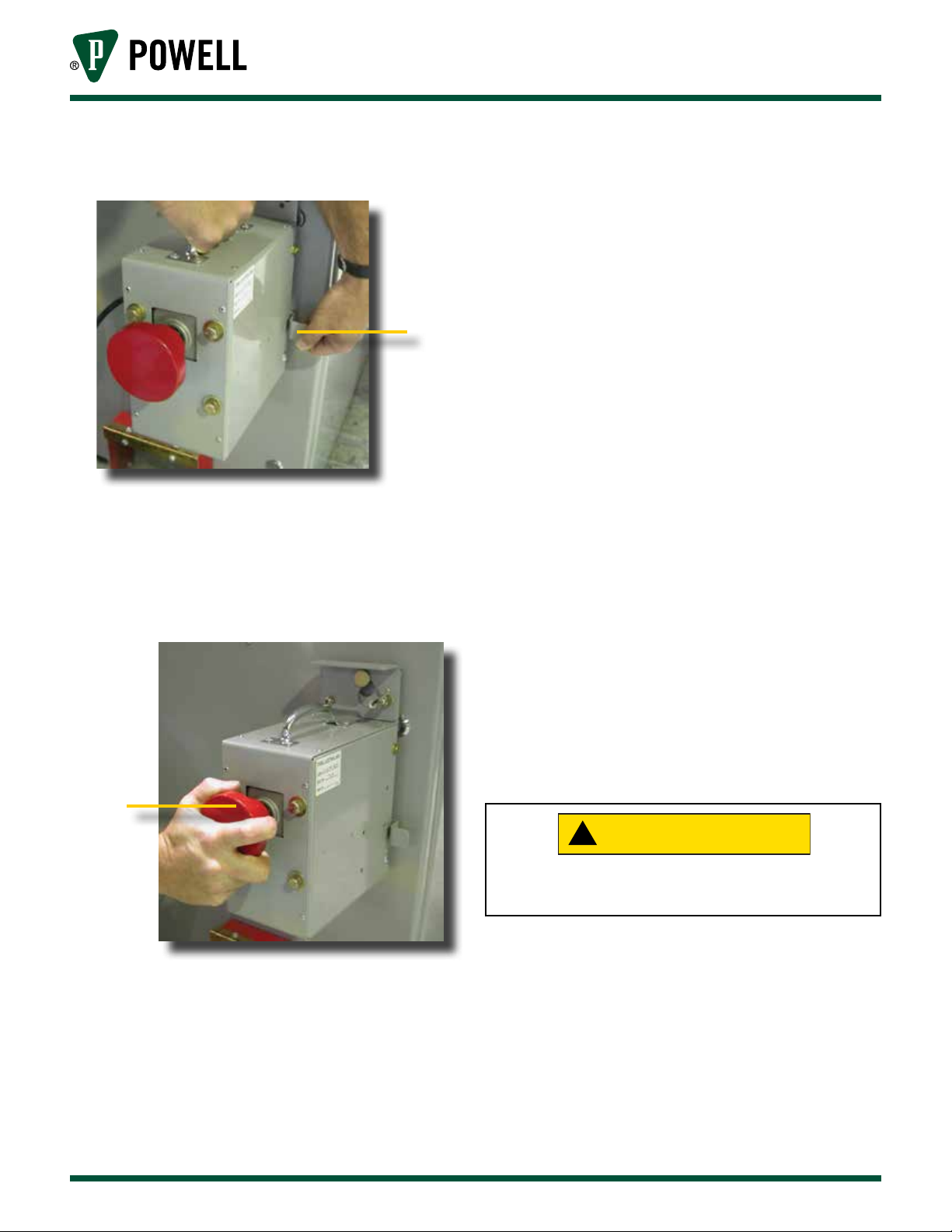

Figure 8 Unlatch the Racking Device Spring

Lock Pin

Figure 9 Insert the Drive Socket into the

Racking Shaft Access Opening

d

b

c

a

a. Drive Socket

b. Circuit Breaker Racking Shaft Access

c. Sliding Support

d. Support Hanger

Figure 10 Push Down the Support Latch

a

b

a. Support Latch

b. Support Lock Pin

Figure 11 Turn the Spring Lock Pin to Secure

the Racking Device on the Support

Lock Pin

a

a. Spring Lock Pin

Powered by Safety®

14 Operation

01.4IB.51051C

PowlVac®Remote Racking Device Assembly

for PowlVac® CDR 5kV & 15kV Circuit Breakers

Figure 12 Lift the Slide Assembly and Engage

the Racking Device Support Hanger

a

a. Slide Assembly Support

Figure 13 Turn the Adjustment Knob to Engage

the Racking Shaft with the Drive

Socket

a

a. Adjustment Knob

2) Performing Circuit Breaker Racking In

Before racking in a circuit breaker, ensure

the remote racking device is installed

properly, refer to Ch 5 Operation,

A. Installing and Operating the Remote

Racking Device for Racking In, 1) Installing

the Remote Racking Device for Circuit Breaker

Racking In.

1. Plug the motor control box power cord

into a 110VAC 15A receptacle.

2. On the motor control box, move the

power switch to the ON position

(Figure 14, d).

3. On the motor control box, turn the

selector switch to IN (Figure 14, c).

4. Depress the black push button on the

selector switch (Figure 14, e). The red

IN indicator lamp will illuminate. The

remote racking device will begin to rack

in the circuit breaker and will vibrate

slightly.

5. When the circuit breaker is fully racked

in, the remote racking device’s torque

limiter will begin to slip and there will

be a clear clicking sound along with a

vibration of the racking device. At this

point, release the push button.

Do not continue to rack in. If done, it may

cause damage to the equipment.

!

CAUTION

6. On the motor control box, move the

power switch to the OFF position.

7. Unplug the motor control box power

cord from the 110VAC 15A electric

receptacle when the racking in

procedure is successfully completed.

Note: To uninstall the remote racking device,

see Ch 5 Operation, C. Uninstalling the

Remote Racking Device.

Table of contents