4

1. PRECAUTIONS AND REQUIREMENTS

1.1 PRECAUTIONS:

1.1.1 VERIFY THAT YOU HAVE THE CORRECT MODEL NUMBER FOR YOUR APPLICATION. REFERENCE MODEL CONFIGURATIONS

(PAGE 20) TO VERIFY YOU HAVE THE CORRECT UNIT. IF NOT, SEE CHANGING HAND DIRECTION (PAGE 15, 9.1).

1.1.2 THE DOOR THAT THE MODEL 2300DL IS TO BE MOUNTED TO SHOULD BE PLUMB, SQUARE, AND NOT WARPED. THE DOOR

SHOULD NOT STICK TO THE JAMB.

1.1.3 THE DOOR THAT THE MODEL 2300DL UNIT IS TO BE MOUNTED TO SHOULD HAVE STANDARD BUTT HINGES, VOID OF ANY

SPRINGS. NO OTHER DOOR OPEN OR CLOSE ASSIST FEATURES SHOULD BE ATTACHED TO THE DOOR. 20 LBS. OF INITIAL

FORCE IS APPLIED AT THE LEADING EDGE OF THE DOOR TO BEGIN THE OPENING AND CLOSING ACTIONS. FLIMSY OR

IMPROPERLY INSTALLED HINGES MAY PREVENT THE DOOR OPENER FROM OPERATING PROPERLY.

1.2 POWER REQUIREMENTS:

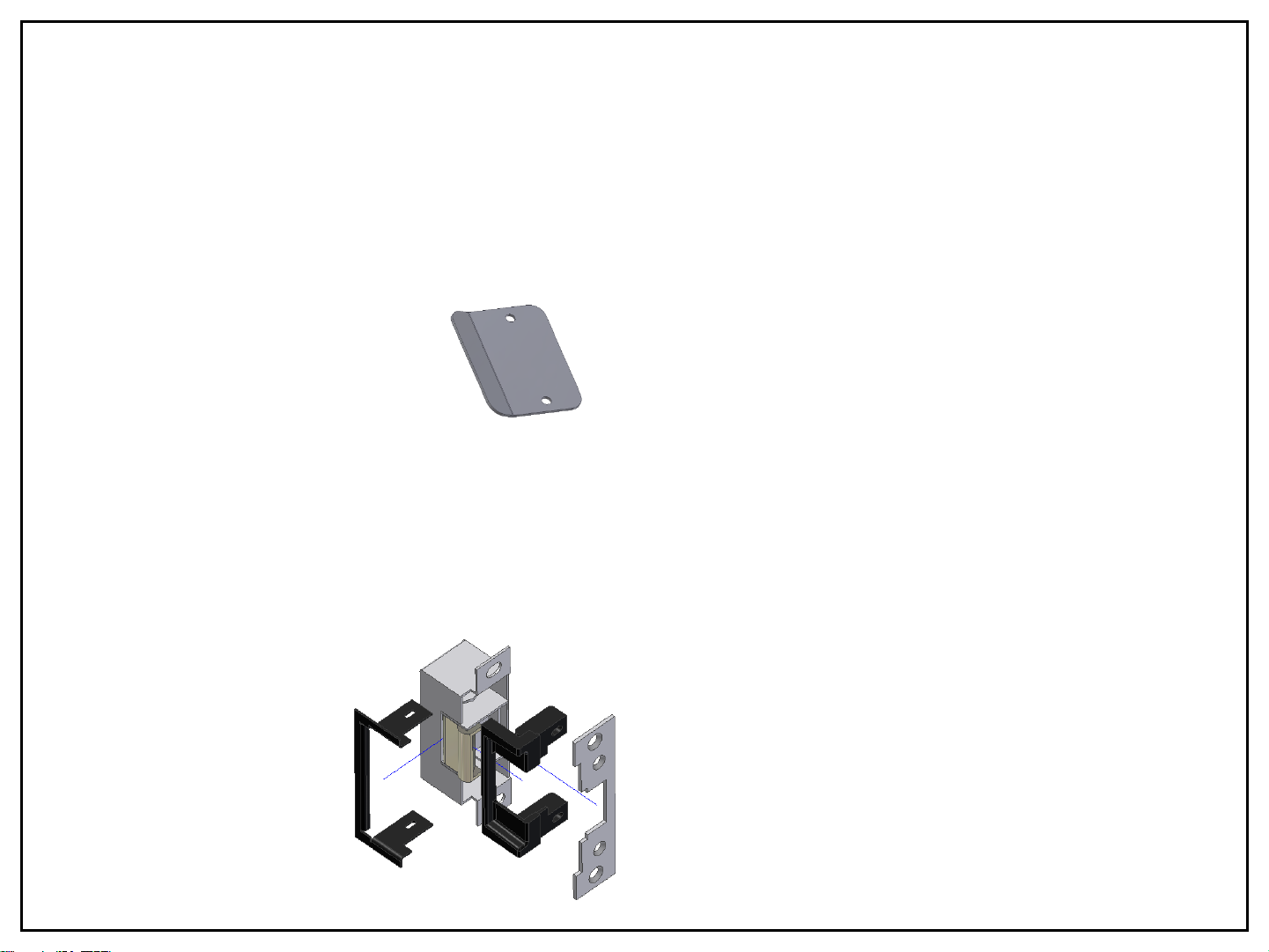

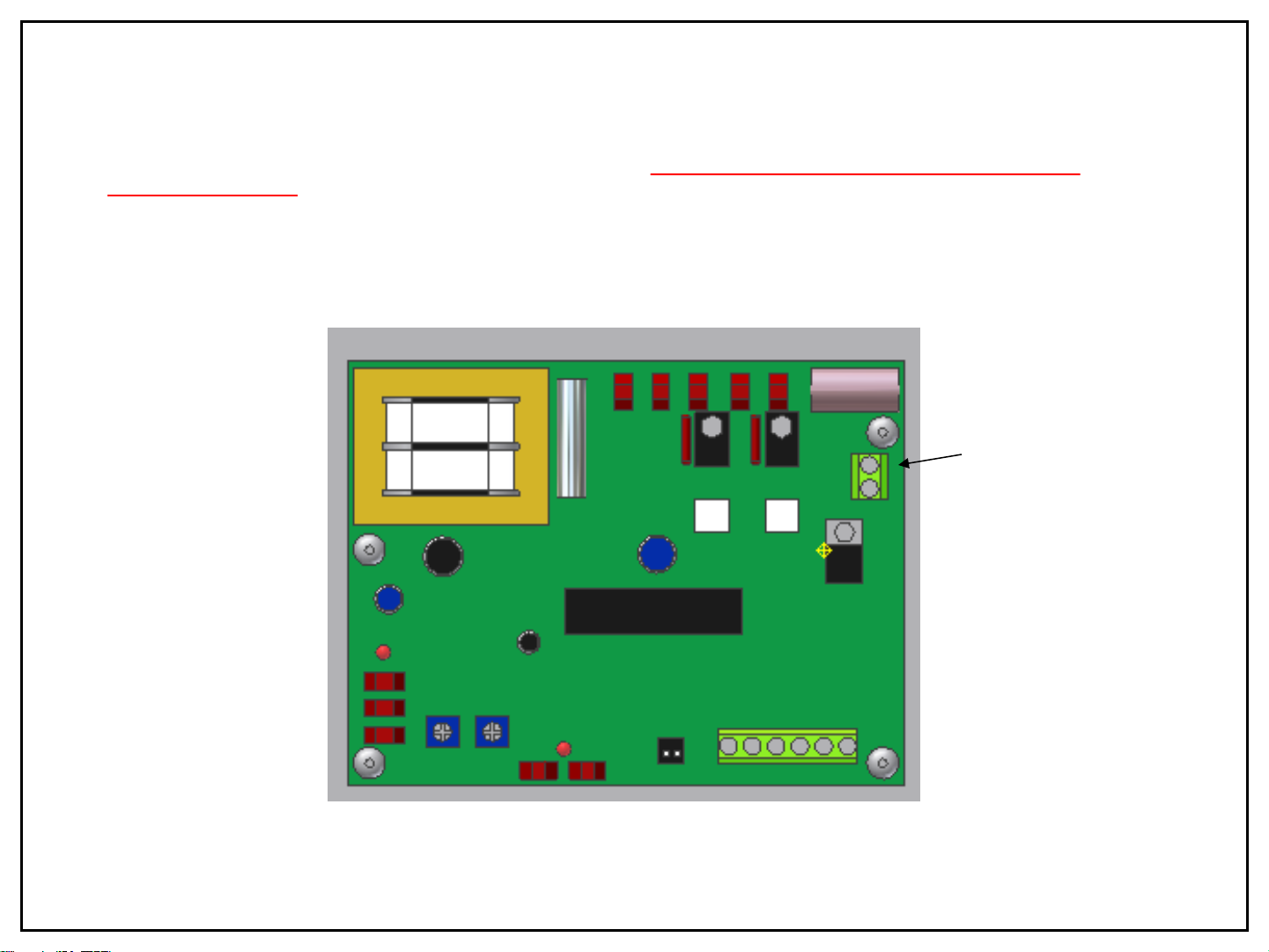

THIS MODEL IS SUPPLIED WITH A 9 FOOT POWER CORD THAT PLUGS INTO A 115V AC OUTLET. WHEN THE OPTIONAL ELECTRIC

STRIKE IS PROVIDED, IT IS SUPPLIED WITH 12 FEET OF LOW VOLTAGE WIRE TO CONNECT THE ELECTRIC STRIKE PLATE TO THE

STRIKE TERMINALS ON THE MAIN CIRCUIT BOARD (SEE PAGES 10 AND 16). THE TERMINALS ARE UNIVERSAL.

WARNING: USE CAUTION AND DISCONNECT POWER WHEN WIRING ELECTRIC STRIKE.

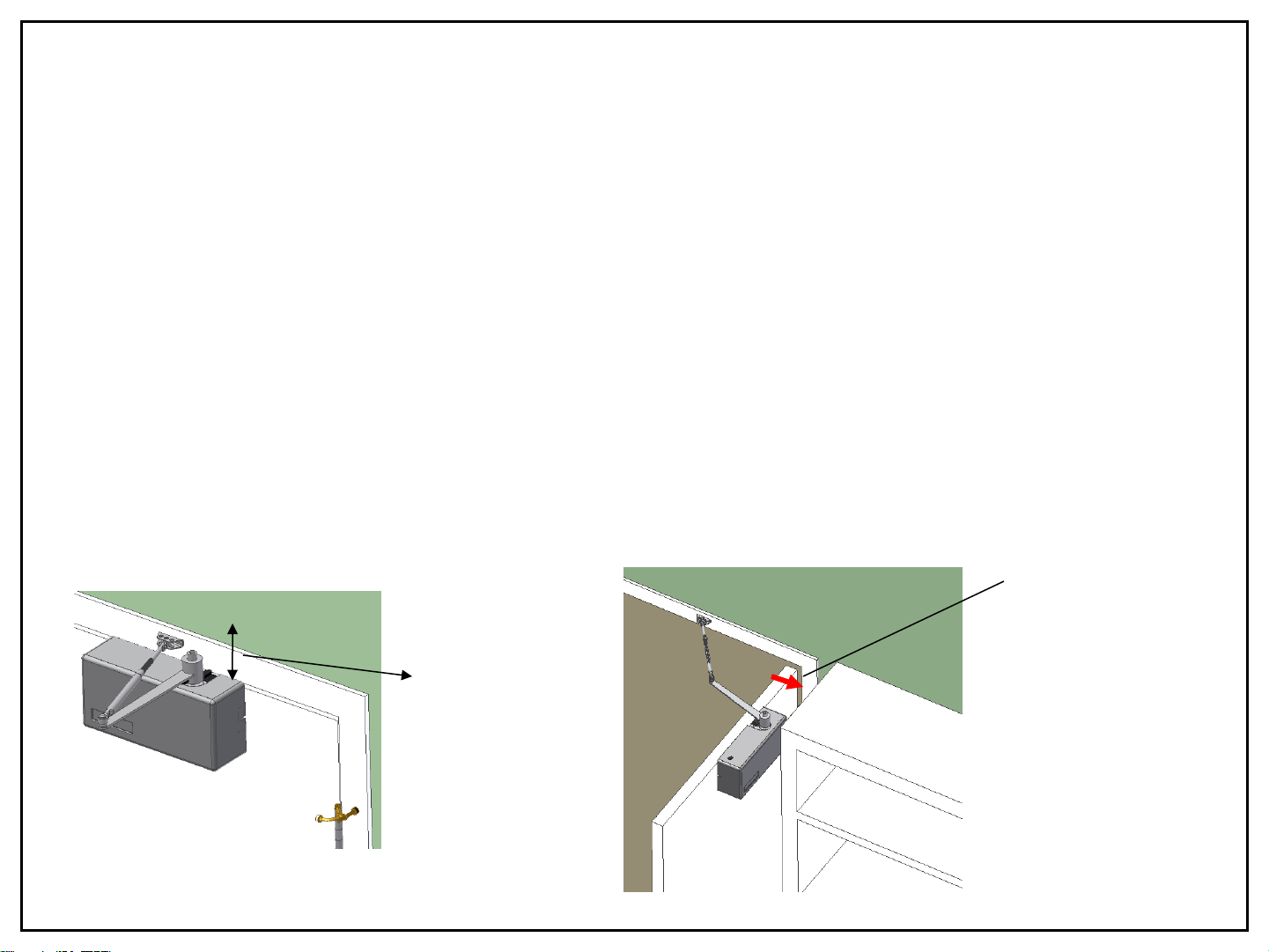

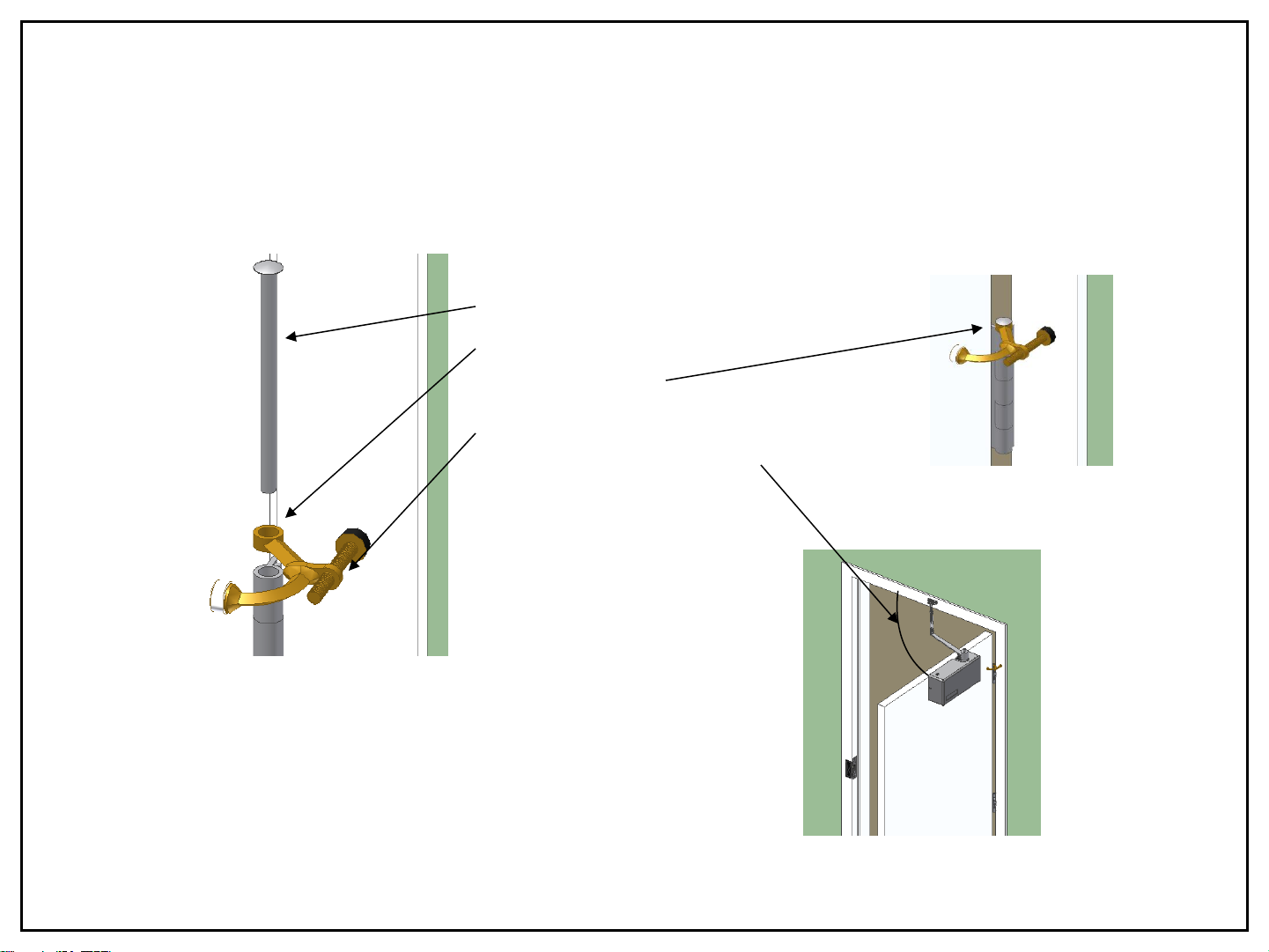

1.3 CLEARANCE REQUIREMENTS:

AT LEAST 3” OF CLEARANCE ABOVE THE TOP OF THE DOOR IS NEEDED. AT LEAST 3-1/2” OF CLEARANCE IS NEEDED FROM THE

HINGE SIDE SURFACE OF THE DOOR TO A PARALLEL OBJECT OR WALL TO ALLOW THE DOOR TO OPEN 90 DEGREES WITHOUT

THE MOTOR MOUNT UNIT BEING OBSTRUCTED.

3” MINIMUM

CLEARANCE FROM

TOP EDGE OF DOOR

TO CEILING

3-1/2 INCH MINIMUM

CLEARANCE FROM

DOOR, WHEN

OPENED 90

DEGREES, TO

PARALLEL OBJECT

OR WALL

U.S Patent 7,418,800 B1 Power Access 2300DL REV 06-18-18 ©