Page 10 of 35 Reference: 708052-1 Issue date: 23-Jul-2014 Revision: B

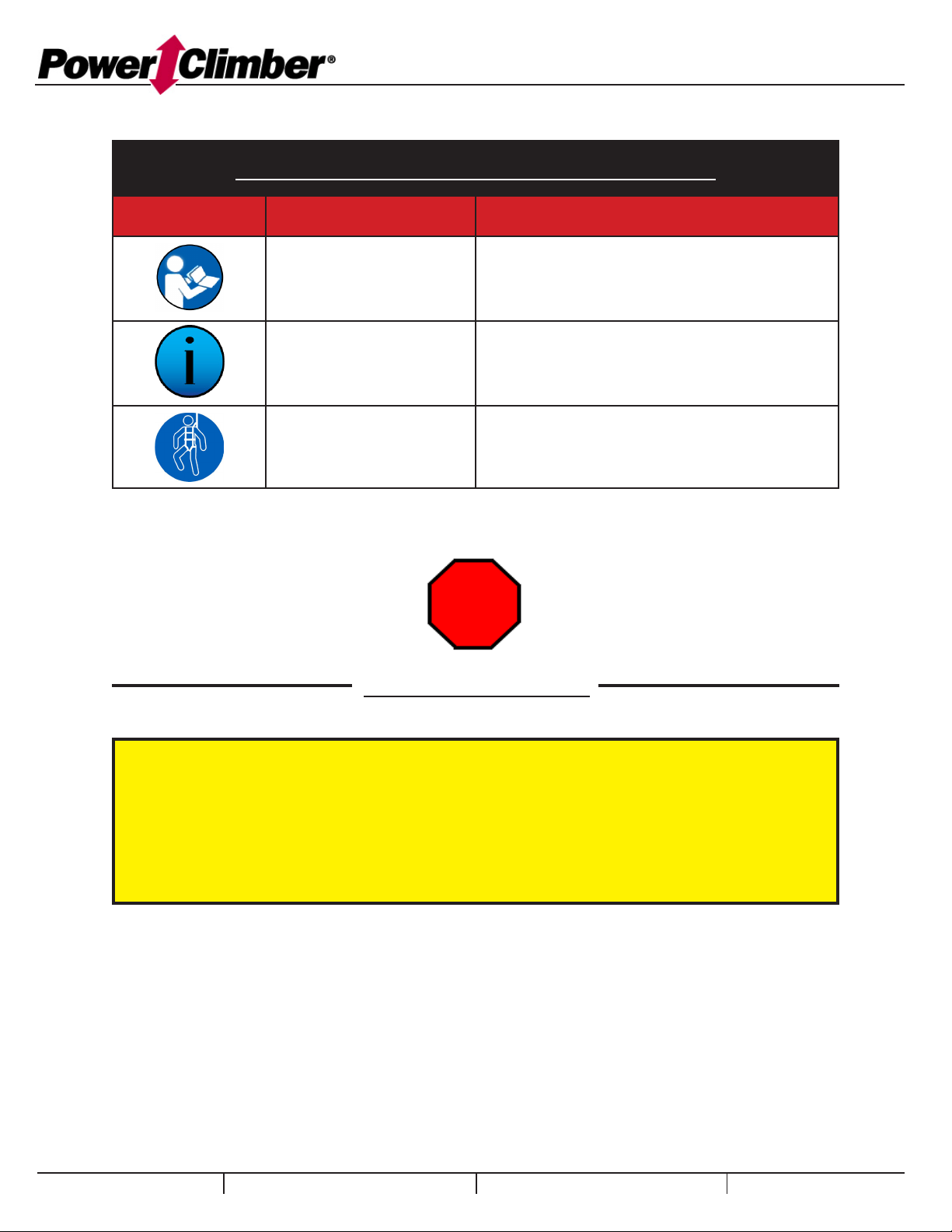

SAFETY SUMMARY

(continued)

9. When welding from a suspended scaffold, provide proper electrical grounding for this hoist.

a. Assure platform is grounded to the structure.

b. Insulate wire rope 4 feet above and below the platform.

c. Insulate wire rope at suspension point and assure that the wire rope cannot contact the

structure along its entire length, including the tail line.

d. Cover the hoist with an insulating material.

11. Never operate an electric hoist in an explosive atmosphere such as a renery, chemical plant, grain

elevator, distilleries, ship or silo interiors, mines, around coal handling equipment, or around

explosive organic vapors or dust.

12. Never use hoists and aluminum platforms around caustic materials, acids, or acid fumes. Use hoist

covers when corrosive materials are present.

13. Maintain clearances and make sure no obstructions interfere with vertical travel.

14. Avoid power lines. Make sure the platform or hand tools cannot swing or be blown within a

minimum of 10 feet of a power line. Check your local codes for minimum distances. Never, under

any circumstances, rig a platform above electrical power lines.

15. Push the operating switch by hand only. Do not use foreign objects to operate the hoist.

16. When not in use, store hoist and stage to protect from unauthorized use. Cover the hoist if possible.

Always unplug power cord when not in use and equipment is not attended.

17. Do not allow anyone under suspended equipment. If necessary, provide protection below the

suspended equipment to prevent injury to people from falling objects. Use lanyards to secure

tools and materials from falling on personnel below.

18. Use approved personnel harnesses, lanyards, rope grabs, and independent lifelines at all times.

Attach the lifelines to a structural member of the building or structure, never to part of the rigging

unless specically designed for this purpose.

19. Comply with all local, provincial and federal safety codes and equipment instructions.

20. Only authorized and properly trained personnel shall operate this hoist. Each operator must

determine his own tness to operate this hoist. Consult your doctor if you are in doubt. Each

operator must not be under the inuence of alcohol or drugs.

21. If you hear any strange noises or if the hoist does not appear to work normally, stop using it

immediately. Do not continue to use the equipment until it is repaired.