Power Fist 8904807 User manual

V4.0 8904807

Please read and understand all instructions before use. Retain this manual for

future reference.

22 Ton Electric Kinetic

Log Splitter

8904807 22 Ton Electric Kinetic Log Splitter V4.0

2 For technical questions call 1-800-665-8685

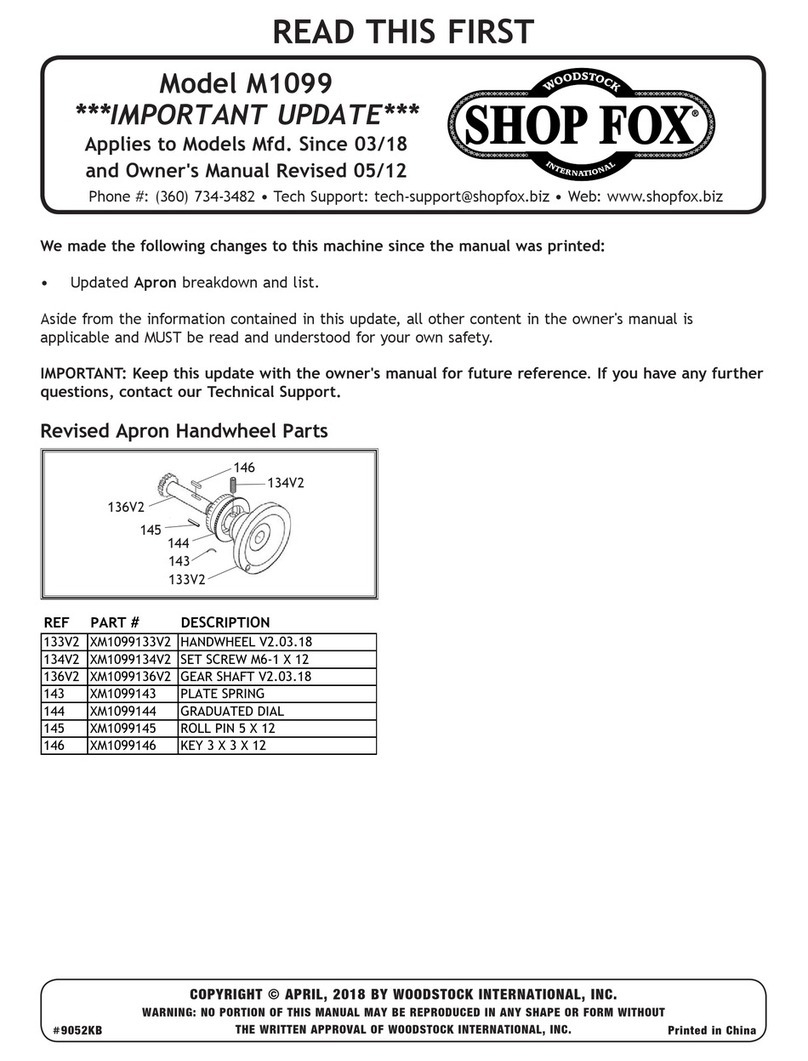

SPECIFICATIONS

Capacity (length x diameter) 21 x 20 in.

Current Rating 9 A

Voltage Rating 120 VAC

HP Rating 2 HP

Max. Splitting Force

22 tons

Cycle Time 2.5 seconds

Handle Type Twin handle operation

Handle Material Steel

Material Steel, cast iron, plastic

Wheel Type Pneumatic rubber

Wheel size 10 x 3.5 in.-4

Size 5 ft

INTRODUCTION

The 22 Ton Electric Kinetic Log Splitter is ideal for splitting logs up to 21 x

20 in. The twin-handle operation makes sure the operator is safe when the

tool is active with its quick 2.5 second cycle time. The pneumatic wheels

make moving the tool easy.

SAFETY

WARNING! Read and understand all instructions before using this tool.

The operator must follow basic precautions to reduce the risk of

personal injury and/or damage to the equipment.

Keep this manual for safety warnings, precautions, operating or inspection

and maintenance instructions.

22 Ton Electric Kinetic

Log Splitter

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 3

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A

notice is an alert that there is a possibility of property damage, injury or

death if certain instructions are not followed.

DANGER! This notice indicates an immediate and specific hazard that will

result in severe personal injury or death if the proper

precautions are not taken.

WARNING! This notice indicates a specific hazard or unsafe practice that

could result in severe personal injury or death if the proper

precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that may

result in minor or moderate injury if proper practices are not

taken.

NOTICE! This notice indicates that a specific hazard or unsafe practice will

result in equipment or property damage, but not personal injury.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean, well-lit and

free of distractions. Place lights so you are not working in a shadow.

2. Keep anyone not wearing the appropriate safety equipment away from the

work area.

3. Store unused tools properly in a safe and dry location to prevent rust or

damage. Lock tools away and keep out of the reach of children.

4. Do not install or use in the presence of flammable gases, dust or liquids.

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the Canadian

Standards Association (CSA) or American National Standards Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side protection for

the eyes. Eye protection equipment should comply with CSA Z94.3-07 or

ANSI Z87.1 standards based on the type of work performed.

8904807 22 Ton Electric Kinetic Log Splitter V4.0

4 For technical questions call 1-800-665-8685

2. Wear the appropriate type of full-face shield in addition to safety

goggles, as the work can create chip, abrasive, or particulate matter.

3. Wear gloves that provide protection based on the work materials or to

reduce the effects of tool vibration.

a. Do not wear gloves when operating a tool that can snag the material

and pull the hand into the tool.

4. Wear protective clothing designed for the work environment and tool.

5. Non-skid footwear is recommended to maintain footing and balance in

the work environment.

6. Wear steel toe footwear or steel toe caps to prevent a foot injury from

falling objects.

7. Wear a NIOSH approved respirator when working on materials that

produce hazardous fumes, dust or particulate matter.

8. This tool can cause hearing damage. Wear hearing protection gear with

an appropriate Noise Reduction Rating to withstand the decibel levels.

PERSONAL PRECAUTIONS

Control the tool, personal movement and the work environment to avoid

personal injury or damage to tool.

1. Do not operate any tool when tired or under the influence of drugs,

alcohol or medications.

2. Avoid wearing clothes or jewelry that can become entangled with the

moving parts of a tool. Keep long hair covered or bound.

3. Do not overreach when operating a tool. Proper footing and balance

enable better control in unexpected situations.

SPECIFIC SAFETY PRECAUTIONS

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use

this tool unsafely or incorrectly, you can suffer serious personal injury.

1. Use the correct tool for the job. This tool was designed for a specific

function. Do not modify or alter this tool or use it for an unintended

purpose.

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 5

2. Do not use the tool if any parts are damaged, broken, or misplaced.

Repair or replace the parts.

3. This log splitter is not suitable for commercial or industrial use.

4. Only use accessories that are specifically approved for this log splitter.

Using non-approved accessories could cause serious injury and could

damage the log splitter.

5. Never operate the tool on slippery, wet, muddy, or icy ground.

6. Only operate the tool on a flat, level surface. Operating on a slope could

cause the tool to roll over or cause logs to fall.

7. Only operate the tool during daylight or under good artificial light.

8. Both ends of the log should be cut as square as possible to help prevent

the log from riding out of the log splitter during operation. Never split a

log that does not completely fit into the work area (20 x 21 in.).

9. Immediately remove split wood from around the log splitter to keep

pieces from flying up and possibly causing injury.

10. Never bend or reach over the log splitter to retrieve a log.

11. Never place any part of your body between the ram and the splitting

wedge during a forward or reverse stroke.

12. Never split more than one log at a time.

13. Never cross-split a log. Always split the log along the grain.

14. This log splitter is designed for operation by a single person. Never have

one person operating the log splitter while another positions the log.

15. Do not attempt to load the log splitter while the ram is moving.

16. Do not move the log splitter while the motor is running. Shut off the motor

and disconnect from the power supply before moving the log splitter.

17. Periodically verify that all nuts, bolts, screws and platforms are properly

tightened.

18. Never leave the log splitter running when unattended. Move the power

switch to the OFF position and then wait for the log splitter to come to a

complete stop before leaving the immediate area.

19. Do not stand on the log splitter. Serious injury could result if the log splitter

falls over, if you fall off, or if you accidentally contact the log splitter.

8904807 22 Ton Electric Kinetic Log Splitter V4.0

6 For technical questions call 1-800-665-8685

ELECTRICAL SAFETY

WARNING! Do not touch or handle a live tool with any part of your body

that is wet or damp. Wet skin reduces resistance to electrical current,

increasing the danger of a serious or fatal shock.

WARNING! To reduce risk of electric shock, be certain that the plug is

connected to a properly grounded receptacle.

1. Disconnect the tool from the power supply before making any

adjustments, changing accessories, cleaning, servicing or when

storing. Such preventive safety measures reduce the risk of starting the

tool accidentally.

2. Protect yourself against electric shocks when working on electrical

equipment. Avoid body contact with grounded surfaces. There is an

increased chance of electrical shock if your body is grounded.

3. Do not expose the tool to rain, snow, frost or any other damp or wet

conditions. Water entering a tool will increase the risk of electric shock.

4. Do not disconnect the power cord in place of using the power switch.

This will prevent an accidental start-up when the power cord is plugged

into the power supply.

a. In the event of a power failure, turn off the machine as soon as the

power is interrupted. The possibility of accidental injury could

occur if the power returns and the unit is not switched off.

5. Do not alter any parts of the tool or accessories. All parts and

accessories are designed with built-in safety features that may be

compromised if altered.

6. Make certain the power source conforms to requirements of your

equipment (see Specifications).

7. When wiring an electrically driven tool, follow all electrical and safety

codes, as well as the most recent Canadian Electrical Code (CE) and

Canadian Centre for Occupational Health and Safety (CCOHS).

8. This tool is only for use on 120 V (single phase) and is equipped with a

three-prong grounded power supply cord and plug. Check with a

qualified electrician if you are in doubt as to whether the outlet is

properly grounded. If the tool should electronically malfunction or

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 7

break down, grounding provides a low resistance path to carry

electricity away from the user.

a. Never remove the grounding prong or modify the plug in any way,

as this will render the tool unsafe.

b. Do not use any adapter plugs.

WARNING! All wiring should be performed by a qualified electrician.

POWER CORD

1. Insert the power cord plug directly to the power supply whenever

possible. Use extension cords or surge protectors only when the tool's

power cord cannot reach a power supply from the work area.

a. When operating a tool outside, use an outdoor extension cord

marked W-A or W. These cords are rated for outdoor use and

reduce the risk of electric shock. Canadian electrical codes require

extension cords to be rated type SJT or better.

b. Use in conjunction with a Ground Fault Circuit Interrupter (GFCI).

It is recommended that the GFCI should have a rated residual

current of 30 mA or less.

2. Do not operate this tool if the power cord is frayed, damaged or poorly

spliced, as an electric shock may occur, resulting in personal injury or

property damage.

a. Inspect the tool's power cord for cracks, fraying or other faults in

the insulation or plug before each use.

b. Discontinue use if a power cord feels more than comfortably warm

while operating the tool.

3. Keep all connections dry and off the ground to reduce the risk of

electric shock. Do not touch the plug with wet hands.

4. Prevent damage to the power cord by observing the following:

a. Do not pull on the cord to disconnect the plug from an outlet.

b. Keep the cord away from heat, oil, sharp edges or moving parts.

c. Never use the cord to carry the tool.

d. Place the electrical cord in a position that prevents it from coming

into contact with the tool and getting caught by the workpiece. The

cord should always stay behind the tool.

8904807 22 Ton Electric Kinetic Log Splitter V4.0

8 For technical questions call 1-800-665-8685

5. Do not allow people, mobile equipment or vehicles to pass over

unprotected power cords.

a. Position power cords away from traffic areas.

b. Place cords in reinforced conduits or place planks on either side of

the power cord to create a protective trench.

UNPACKING

WARNING! Do not operate the tool if any part is missing. Replace the

3missing part before operating. Failure to do so could result in a

malfunction and personal injury.

Remove the parts and accessories from the packaging and inspect for damage.

IDENTIFICATION KEY

A Mobility Handle

B Splitting Wedge

C Carriage

D Ram

E Safety Clutch Handle

F Ram Release Handle

G ON/OFF Switch

H Power Cord

I Belt & Flywheel

Cover (2)

J Rear Bracket

K Wheel (2)

L Front Bracket

M Motor

N Drive Belt

O Ram Return Sprng

P Flywheel (2)

ASSEMBLY & INSTALLATION

Dashed numbers in parenthesis (Fig. 1-1) refer to a specific point in an

illustration or image.

Have a second person help you assemble the tool.

1. Remove the log splitter from the packaging and place it on a flat, level floor.

Fig. 1

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 9

2. Clean all rust-protected parts with an ordinary household grease or

spot remover. Do not use gasoline, paint thinner, or mineral spirits, as

they may damage painted surfaces.

3. Install the front bracket (Fig. 2-5) and rear bracket (Fig. 2-4) onto the

log splitter.

4. Install the two wheels (#54) onto the rear bracket (Fig. 2-4).

5. Install the tray (Fig 2-1) onto the log splitter.

6. Thread the Safety Clutch Handle

(Fig. 2-2) onto the small stud

protruding from the housing.

7. Thread the Ram Release Handle

(Fig. 2-3) onto the large stud below

the housing.

OPERATION

WARNING! Always operate the log splitter from the rear during the

splitting task to protect yourself from ejected splinters or pieces of

wood, expecially when splitting irregular or knotty wood.

BEFORE USE

1. Verify that the log splitter is on a flat and stable surface prior to

operation.

2. Verify that all nuts and bolts are tight. Make sure the log splitter is in

good condition before use.

3. Operate the log splitter from the back of the unit behind the motor.

Familiarize yourself with the operating sequence by practicing without

logs before use.

4. Maintain a clear area free from obstructions, including split and unsplit logs.

OPERATING THE LOG SPLITTER

IMPORTANT! The area beneath the ram can accumulate debris and

splinters, which can prevent the ram from fully returning to the start

position. Keep this area clear of debris to ensure correct operation.

Fig. 2

8904807 22 Ton Electric Kinetic Log Splitter V4.0

10 For technical questions call 1-800-665-8685

1. Plug the log splitter into an appropriate power source.

2. Turn on the unit and allow the motor to reach full speed.

3. Load a log onto the Carriage and

place it against the Splitting Wedge.

Do not load a log against the Ram.

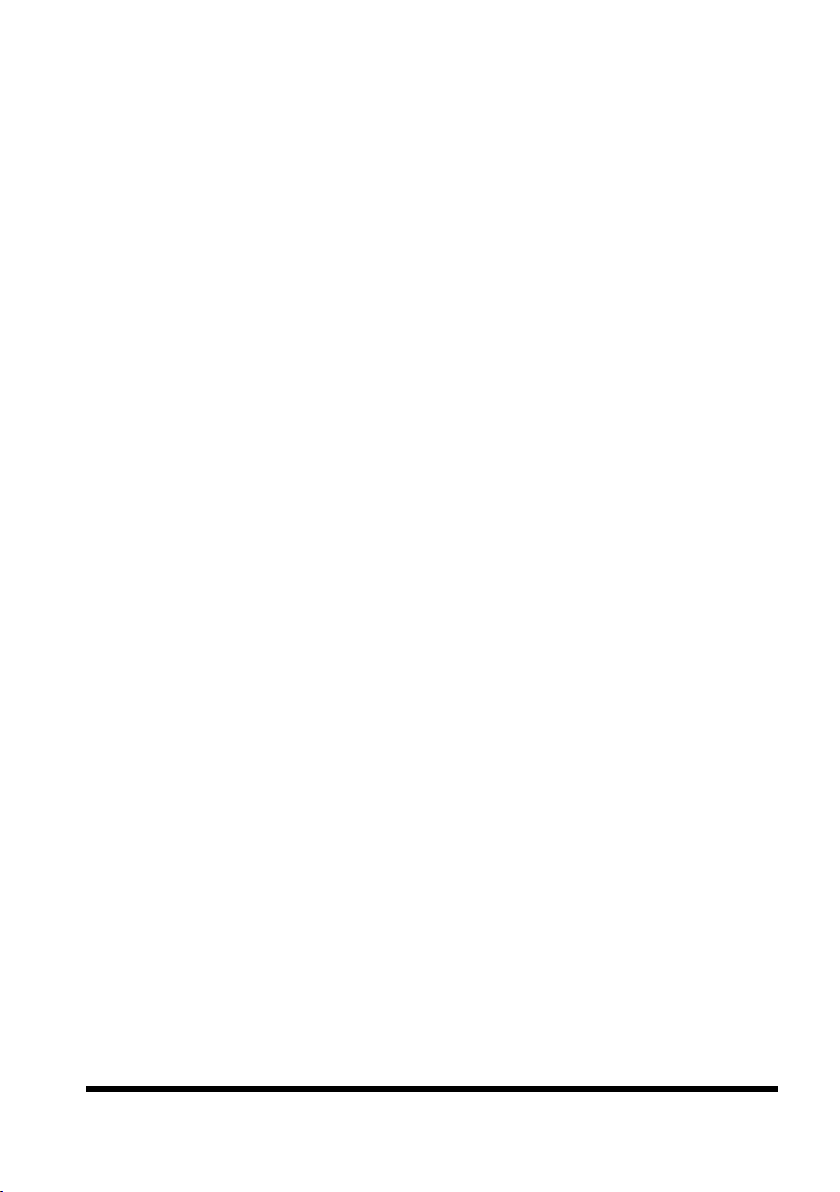

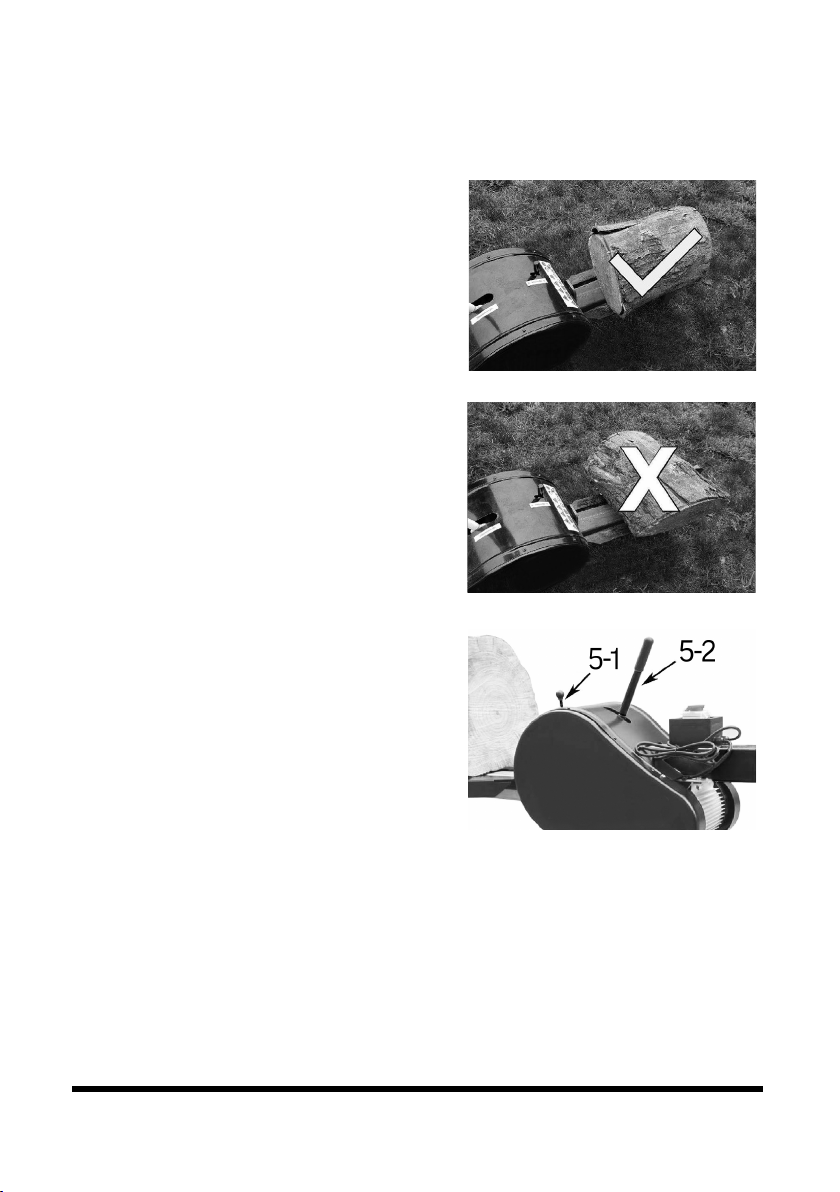

4. Always split the log against the grain

(Fig. 3). Do not attempt to split

against the grain (fig. 4)

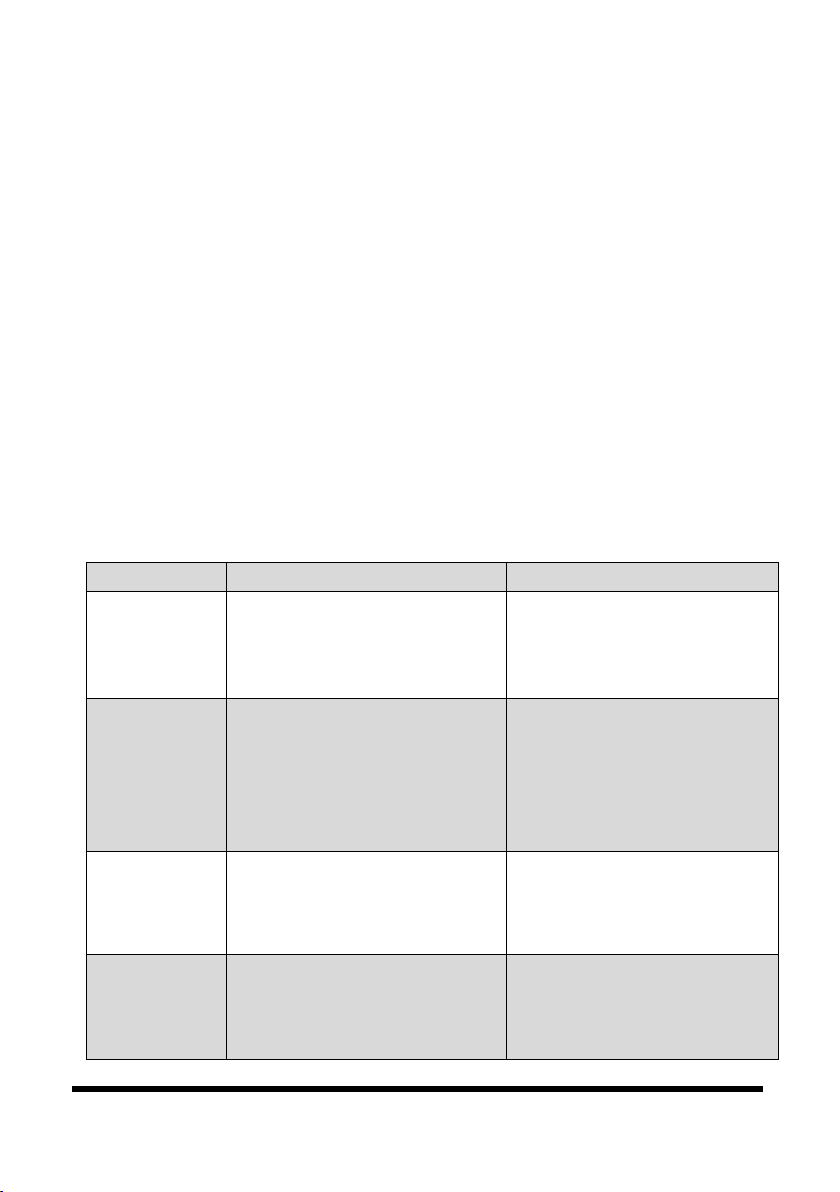

5. For safety, splitting a log is a two-

handed operation. Place one hand on

the Safety Clutch Handle (Fig. 5-1)

and one hand on the Ram Release

Handle (Fig. 5-2).

6. Push the Clutch Handle toward the

log and then hold it in position.

7. Push the Ram Release Handle

forward towards the log. The Ram

will release and push the log

through the Splitting Wedge.

8. Release both handles. The Ram will

retract and reload for the next

splitting operation.

9. If the log is partially split (knot) or stuck

on the Splitting Wedge, then repeat the

steps above You may need to reorient

the log on the carriage.

CARE & MAINTENANCE

1. Maintain the tool with care. A tool in good condition is efficient, easier

to control and will have fewer problems.

2. Inspect the tool components periodically. Repair or replace damaged or

worn components. Only use identical replacement parts when servicing.

3. Follow instructions for lubricating and changing accessories.

Fig. 4

Fig. 3

Fig. 5

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 11

4. Keep the tool handles clean, dry and free from oil/grease at all times.

5. Do not use compressed air near the bearings when cleaning the log splitter.

6. Maintain the tool’s labels and name plates. These carry important information.

If unreadable or missing, contact Princess Auto Ltd. for replacements.

WARNING! Only qualified service personnel should repair the tool. An

improperly repaired tool may present a hazard to the user and/or others.

LUBRICATION

NOTICE! NEVER use a penetrating oil to lubricate the tool. Penetrating oil

may act as a solvent that can break down the grease and cause the tool

to seize up.

1. Lubricate the surface of the beam, the meshing parts of the gear shaft

(#2) and rack (#33) with light machine oil weekly or every 30 hours.

2. Use a little oil to prevent rust on other metal parts.

DRIVE BELT ADJUSTMENT/REPLACEMENT

Numbered references in parenthesis (#1) refer to the included Parts List.

1. Unplug the log splitter.

2. Remove the left and right Belt Covers (#50 and

#51) by loosening two 10 mm bolts (#76) and

six Phillips head bolts (#77) per cover.

3. Remove the Safety Clutch and Ram Release

Handles.

4. Loosen the four 13 mm Hex Nuts (#81, Fig. 6) and

then slide the motor towards the Flywheel (#3).

5. Remove the Drive Belt (#60) from the Motor

Pulley (#59) and the Flywheel.

6. Replace the Drive Belt.

7. Tension the Drive Belt by sliding the motor

away from the Flywheel. Adjust the Drive Belt

until there is 3/8 in. deflection (Fig. 7-1).

8. Tighten the four 13 mm Hex Nuts (#81) securing the motor.

9. Reinstall the safety clutch and ram release handles, then replace the left

and right Belt Covers.

Fig. 6

Fig. 7

8904807 22 Ton Electric Kinetic Log Splitter V4.0

12 For technical questions call 1-800-665-8685

STORAGE

Do not store the log splitter outside. Exposure to rain and ice can damage it.

Keep the log splitter in a cool, dry place that is out of direct sunlight.

REMOVAL FROM STORAGE

Lubricate the log splitter as described in the Lubrication section and then

perform all tasks in Operation Before Each Use section.

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not function

properly or parts are missing. If unable to do so, have a qualified technician

service the tool.

Problem(s)

Possible Cause(s)

Suggested Solution(s)

Log splitter will

not start.

1. Power cord is not plugged in.

2. Fuse or circuit tripped.

3. Damaged power cord.

4. Burned or failed power switch.

1. Plug in saw to power source.

2. Replace fuse or reset breaker.

3. Contact Technical Support.

4. Contact Technical Support.

Log does not

split.

1. Log positioned incorrectly on

carriage.

2. Log exceeds maximum

allowable size.

3. Large knot in log.

1. Re-position log on carriage

against wedge.

2. Maximum allowable log size is

20 x 21 in.

3. Repeat splitting function with

log in place.

Ram retracts

slowly or not at

all.

1. Debris in the rack system.

2. Damaged or worn return

spring.

1.

Clean and lube the rack system

periodically.

2. Inspect return spring and

replace if needed.

Drive belt noise

during start up or

while splitting.

1. Loose drive belt.

2. Worn drive belt.

3. Drive belt is wet from outdoor

use.

1. Tighten drive belt.

2. Replace drive belt.

3. Dry and clean drive belt.

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 13

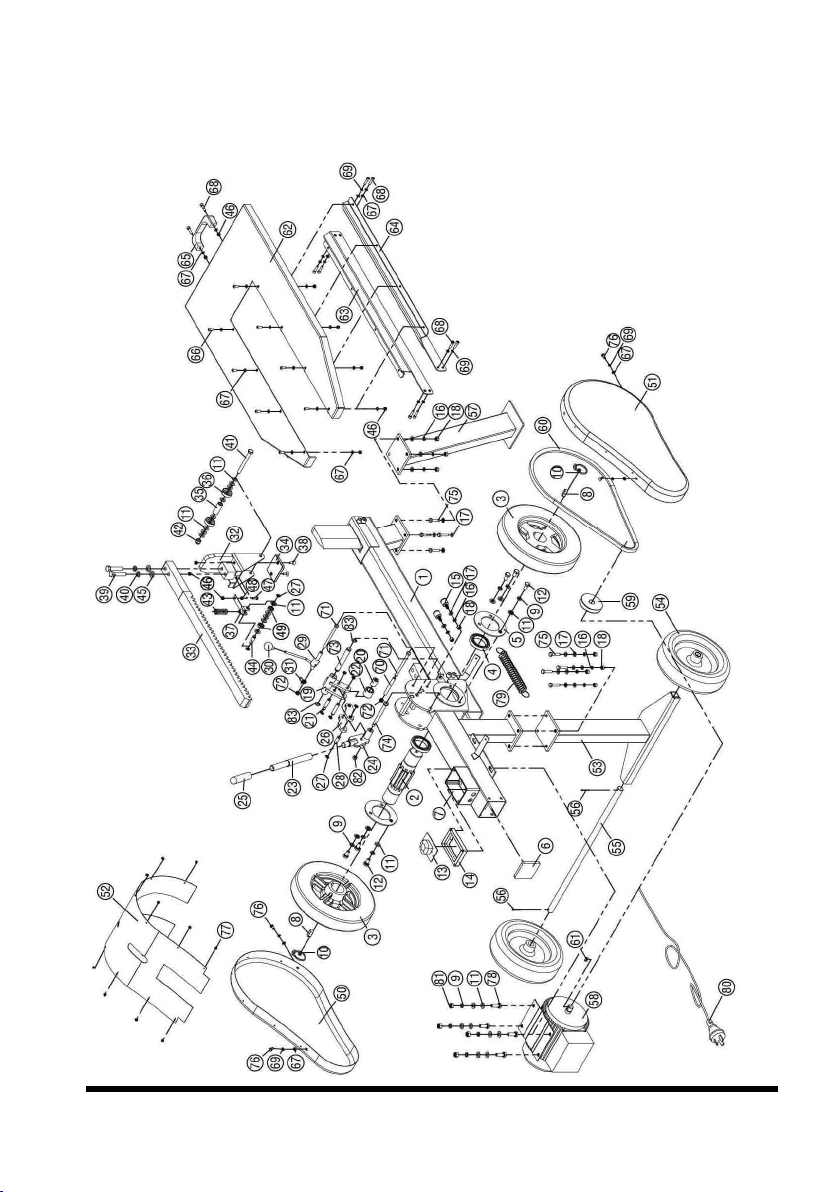

PARTS BREAKDOWN

8904807 22 Ton Electric Kinetic Log Splitter V4.0

14 For technical questions call 1-800-665-8685

PARTS LIST

# PART QTY

1

Splitter Body

1

2 Gear Shaft 1

3 Fly wheel 2

4 Bearings 2

5

Bearing Cap

2

6 Tube Cap 1

7

Switch Box

1

8 Key 2

9

Spring Washer Ø10

10

10 Shaft Circlip 2

11 Flat Washer Ø10 27

12 Bolts M10 6

13

ON-OFF Switch

1

14 Switch Box Cap 1

15

Rubber Bolt M8

2

16 Spring Washer Ø8 10

17

Flat Washer Ø8

18

18 Nuts M8 10

19

Connecting Rod-B

1

20 Inner Roller 1

21 Long Pin Ø10 2

22 Outer Roller 1

23

Safety Clutch Handle

1

24 Operating lever Roller 1

25

Plastic Handle

1

26 Connecting Rod-A 2

27

Circlip Ø10

8

28 Short Pin 1

29 Lock Lever 1

# PART QTY

30

Plastic Handle

1

31 Torsional Spring 1

32 Pusher 1

33 Rack 1

34

PP Plate

1

35 Spacer 1

36

Bearing

2

37 Spring Stand 1

38

Countersunk Head Bolts

2

39 Bolts M12 2

40 Spring Washer Ø12 2

41 Bolt M10 1

42

Lock Nut M10

1

43 Spring 1

44

Pin Shaft

1

45 Flat Washer Ø12 2

46

Lock Nut M6

13

47 Bolt M6 1

48

Nut M6

1

49 Bearings 2

50 Belt Cover L 1

51 Belt Cover R 1

52

Operating Hood

1

53 Rear Bracket 1

54

Rubber Wheel

2

55 Wheel Axle 1

56

Split Pin

2

57 Front Bracket 1

58 Motor 1

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 15

#

PART

QTY

59 Motor Pulley 1

60 Drive Belt 1

61 Motor Key 1

62

Tray

1

63 Tray Bracket-L 1

64

Tray Bracket-R

1

65 Carry Handle 1

66

Bottom Head Bolt M6

8

67 Flat Washer 26

68

Socket Head Bolt

10

69 Spring Washer 12

70 Round Tube 1

71 Hex Bolt M8x110 2

#

PART

QTY

72 Lock Nut M8 2

73 Pin Shaft Ø15 1

74 Bolt M12x110 1

75

Bolt M8

8

76 Bolt M6 4

77

Philips Head Screw

12

78 Bolt M10 4

79

Spring

1

80 Power Cord 1

81

Hex Nut M10

4

82 Lock Nut M12 1

83 Spring Washer Ø15 2

8904807 22 Ton Electric Kinetic Log Splitter V4.0

16 For technical questions call 1-800-665-8685

V4.0 22 Ton Electric Kinetic Log Splitter 8904807

Visit www.princessauto.com for more information 17

8904807 22 Ton Electric Kinetic Log Splitter V4.0

18 For technical questions call 1-800-665-8685

V 4,0 8904807

Vous devez lire et comprendre toutes les instructions avant d'utiliser l'appareil.

Conservez ce manuel afin de pouvoir le consulter plus tard.

Manuel d'utilisateur

Fendeuse de bûches

cinétique électrique,

22 tonnes

8904807 Fendeuse de bûches cinétique électrique, 22 tonnes V 4,0

2 En cas de questions techniques, appelez le 1-800-665-8685

SPÉCIFICATIONS

Capacité (longueur x diamètre) 21 x 20 po

Courant nominal 9 A

Tension nominale 60 Hz, 120 V c.a.

Puissance nominale en CV 2 CV

Force de fendage max.

22 tonnes

Temps de cycle 2,5 secondes

Type de manche Fonctionnement à poignée double

Matériau de manche Acier

Matériau Acier, fonte et plastique

Type de roue Pneumatique, caoutchouc

Taille de roue 10 x 3,5 po – 4

Taille 5 pi

INTRODUCTION

La fendeuse de bûches cinétique électrique de 22 tonnes est idéale pour fendre

des bûches jusqu’à 21 x 20 po. Le fonctionnement à deux poignées permet de

s’assurer que l’opérateur est en sécurité lorsque la fendeuse fonctionne à un

temps de cycle rapide de 2,5 secondes. Les roues à bandage pneumatique

facilitent le déplacement de la fendeuse.

SÉCURITÉ

AVERTISSEMENT ! Veuillez lire et comprendre toutes les instructions avant

d'utiliser cet outil. L'utilisateur doit respecter les précautions de base

lorsqu'il utilise cet outil afin de réduire le risque de blessure ou de

dommage à l'équipement.

Fendeuse de bûches

cinétique électrique,

22 tonnes

Table of contents

Languages:

Popular Lathe manuals by other brands

Rikon Power Tools

Rikon Power Tools 70-150VSR Operator's manual

Jet

Jet JWL-1642EVS Operating instructions and parts manual

HAMAR LASER

HAMAR LASER L-702 Operation manual

Scheppach

Scheppach DM600VARIO Translation of original instruction manual

Grizzly

Grizzly G9972Z owner's manual

Promac

Promac PBD-2555V operating instructions