3.0IMPORTANTSAFETY

INSTRUCTIONS

READALLINSTRUCTIONSBEFOREUSINGTHISLATHE.

–Toreduceriskofinjury:

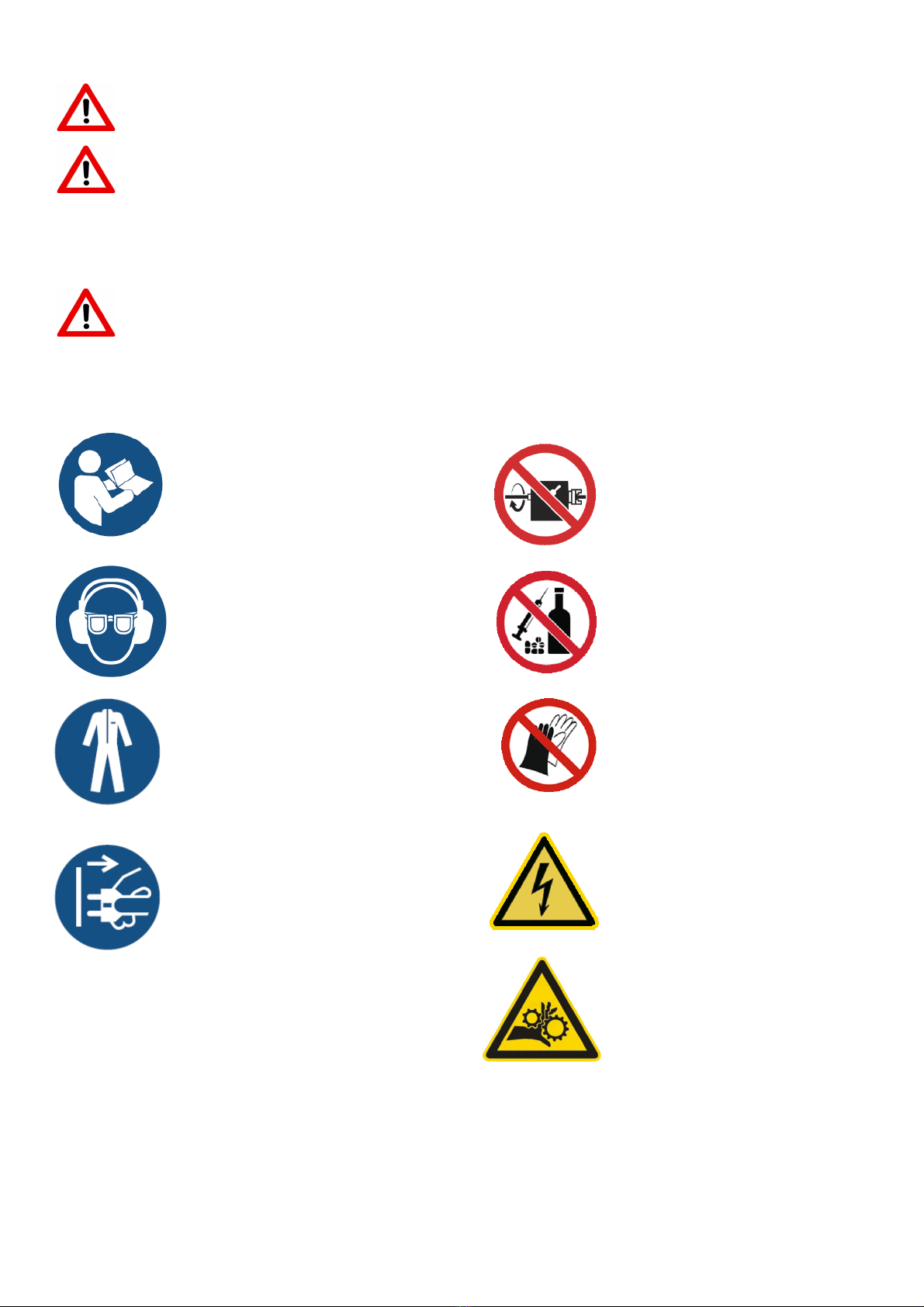

1. Read and understand entire owner’s manual before

attemptingassemblyoroperationofthismachine.

2. Read and understand the warnings posted on the

machineandinthismanual.

3. Replace warning labels if they become obscured or

removed.

4. Thismachineisdesignedandintendedforusebyproperly

trained and experienced personnel only. If you are not

familiarwiththeproperandsafeoperationofametal

lathe, do not use until proper training and knowledge

havebeenobtained.

5. Donotusethismachineforotherthanitsintendeduse.If

used for other purposes, PROMAC disclaims any real or

impliedwarrantyandholdsitselfharmlessfromanyinjury

thatmayresultfromthatuse.

6. Alwayswearapprovedsafetyglassesorfaceshieldwhile

usingthismachine.(Everydayeyeglassesonlyhaveimpact

resistantlenses;theyarenotsafetyglasses.)

7. Beforeoperatingthismachine,removetie,rings,watches

andotherjewellery, and roll sleevesuppastthe elbows.

Remove loose clothing and confine long hair. Non‐slip

footwear or anti‐skid floor strips are recommended. Do

notweargloves.

8. Wearhearingprotection(plugsormuffs)duringextended

periodsofoperation.

9. Some dust created by sawing may contain chemicals

knowntocausecancer,birthdefectsorother

reproductive harm. Some examples of these chemicals

are:

Leadfromleadbasedpaint.

Crystalline silica from bricks, cement and other

masonryproducts.

Arsenic and chromium from chemically treated

lumber.

Yourriskofexposurevaries,dependingonhowoftenyou

dothistypeofwork.Toreduceyourexposuretothese

chemicals, work in a well‐ventilated area and work with

approved safety equipment, such as face or dust masks

that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the

influenceofdrugs,alcoholoranymedication.

11. MakecertaintheswitchisintheOFF position before

connectingthemachinetothepowersupply.Turnoffall

controlsbeforeunplugging.

12. Makecertainthemachineisproperlygrounded.Connect

to a properly grounded outlet only. See Grounding

instructions.

13. Make all machine adjustments or maintenance with the

machineunpluggedfromthepowersource.

14. Removeadjustingkeysandwrenches.Formahabitof

checking to see that keys and adjusting wrenches are

removedfromthemachinebeforeturningiton.

15. Keepsafetyguardsinplaceatalltimeswhenthemachine

is in use. If removed for maintenance purposes, use

extremecautionandreplacetheguardsimmediatelyafter

maintenanceiscomplete.

16. Checkdamagedparts.Beforefurtheruseofthemachine,

aguardorotherpartthatisdamagedshouldbecarefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment of

movingparts,bindingofmovingparts,breakageofparts,

mounting and any other conditions that may affect its

operation.A guardor other partthat isdamaged should

beproperlyrepairedorreplaced.

17. Provide for adequate space surrounding work area and

non‐glare,overheadlighting.

18. Keeptheflooraroundthemachinecleanandfreeofscrap

material,oilandgrease.

19. Keep visitors a safe distance from the work area. Keep

childrenaway.

20. Make your workshop child proof with padlocks, master

switchesorbyremovingstarterkeys.

21. Give your work undivided attention. Looking around,

carrying on a conversation and “horse‐play” are careless

actsthatcanresultinseriousinjury.

22. Keep an ergonomic body position. Maintain a balanced

stanceatalltimessothatyoudonotfallorleanagainst

thechuckorothermovingparts.Donotoverreachoruse

excessiveforcetoperformanymachineoperation.

23. Usetherighttoolatthecorrectspeedandfeedrate.Do

notforceatoolorattachmenttodoajobforwhichitwas

not designed. The right tool will do the job better and

safer.

24. Themachineisintendedforindooruse.Toreducetherisk

ofelectricshock,donotuseoutdoorsoronwetsurfaces.

25. Donothandleplugormachinewithwethands.

26. Userecommendedaccessories;improperaccessoriesmay

behazardous.

27. Maintain tools with care. Keep tools sharp and clean for

the best and safest performance. Follow instructions for

lubricatingandchangingaccessories.

28. Turn off machine and disconnect from power before

cleaning.Useabrushorcompressedairtoremovechips

ordebris;donotusebarehands.

29. Donotstandonthemachine.Seriousinjurycouldoccurif

themachinetipsover.

30. Never leave the machine running unattended. Turn the

poweroffanddonotleavethemachineuntilitcomesto

acompletestop.

31. Remove loose items and unnecessary work pieces from

theareabeforestartingthemachine.

32. Pullthemainsplugifthemachineisnotinuse.

33. Makesuretheworkpieceissecurelyclamped.