Table of Contents

SECTION 5: ACCESSORIES......................... 42

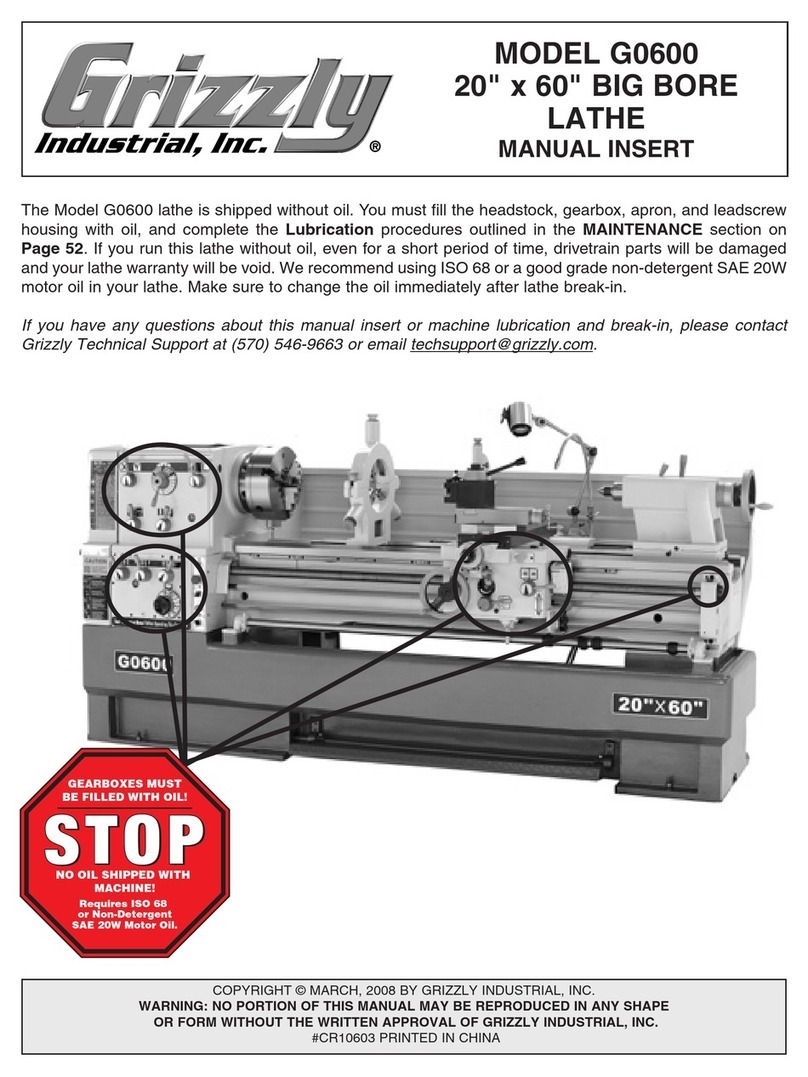

SECTION 6: MAINTENANCE......................... 46

SECTION 7: SERVICE ................................... 53

SECTION 8: WIRING...................................... 63

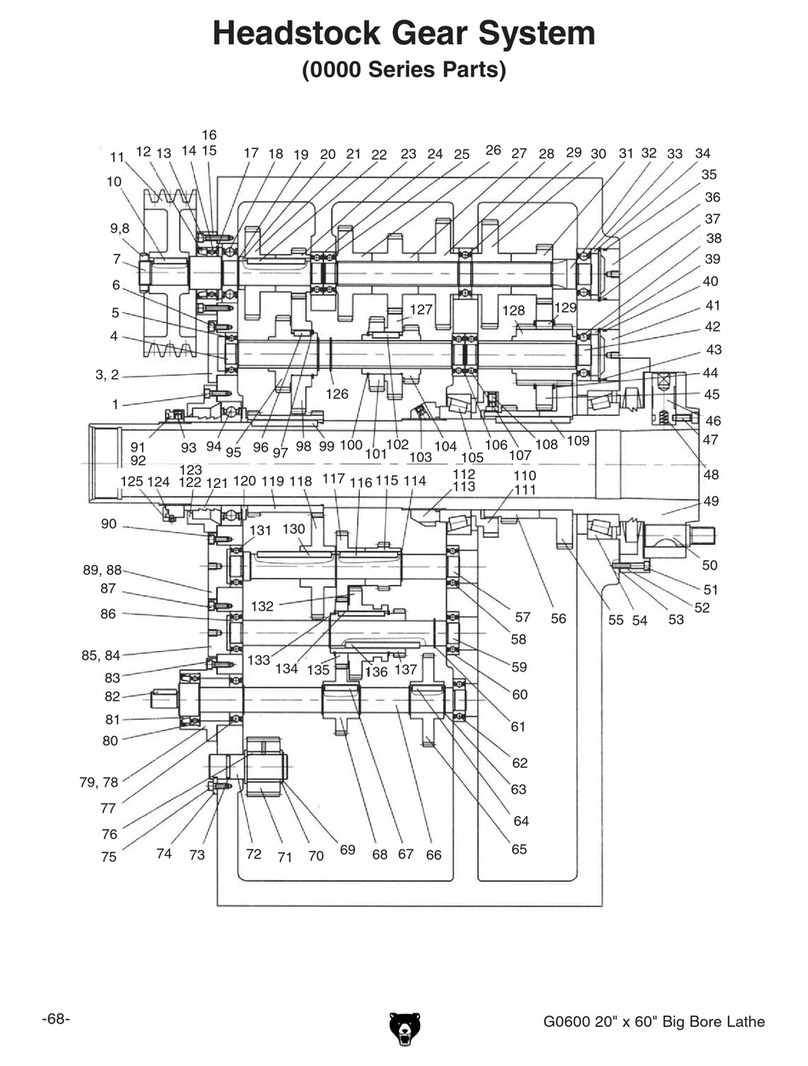

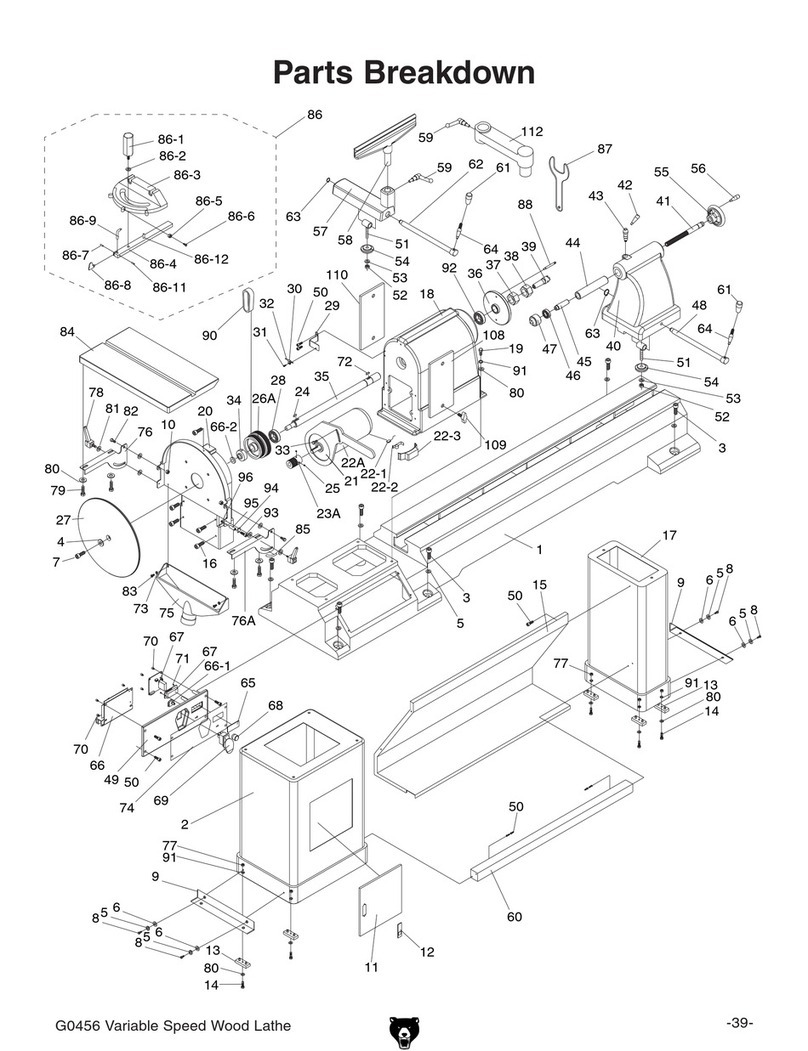

SECTION 9: PARTS....................................... 67

WARRANTY AND RETURNS ........................ 89

INTRODUCTION............................................... 2

SECTION 1: SAFETY....................................... 7

SECTION 2: CIRCUIT REQUIREMENTS ...... 10

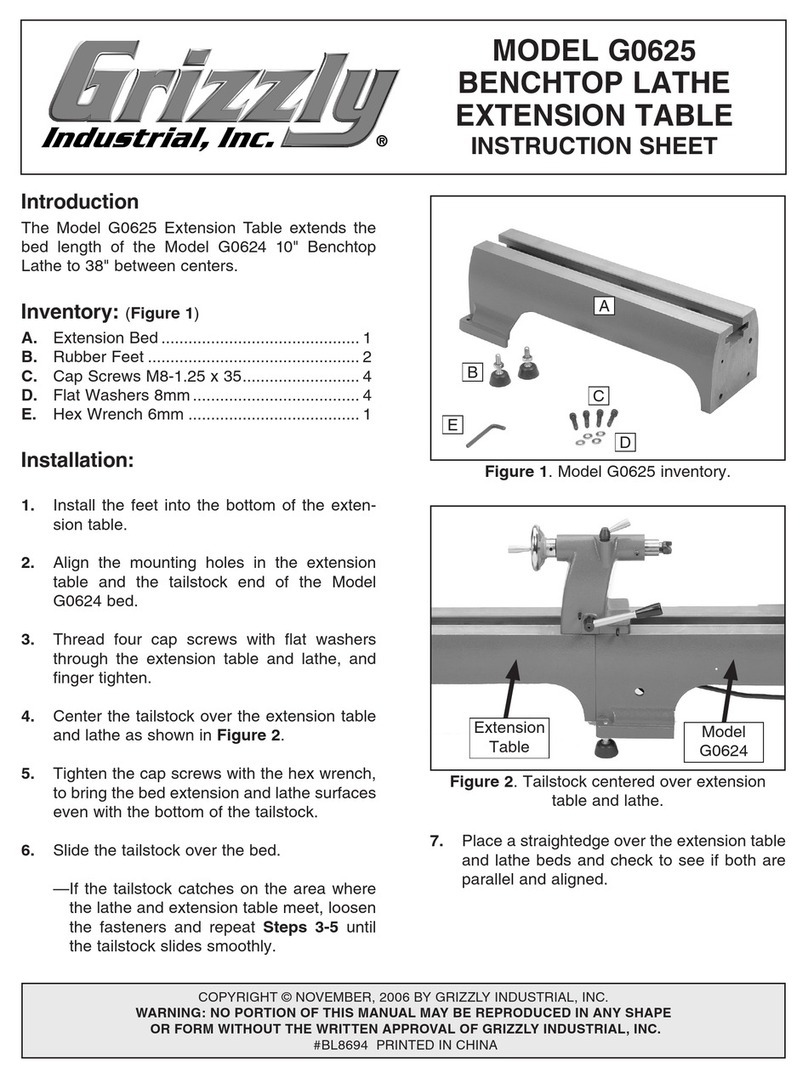

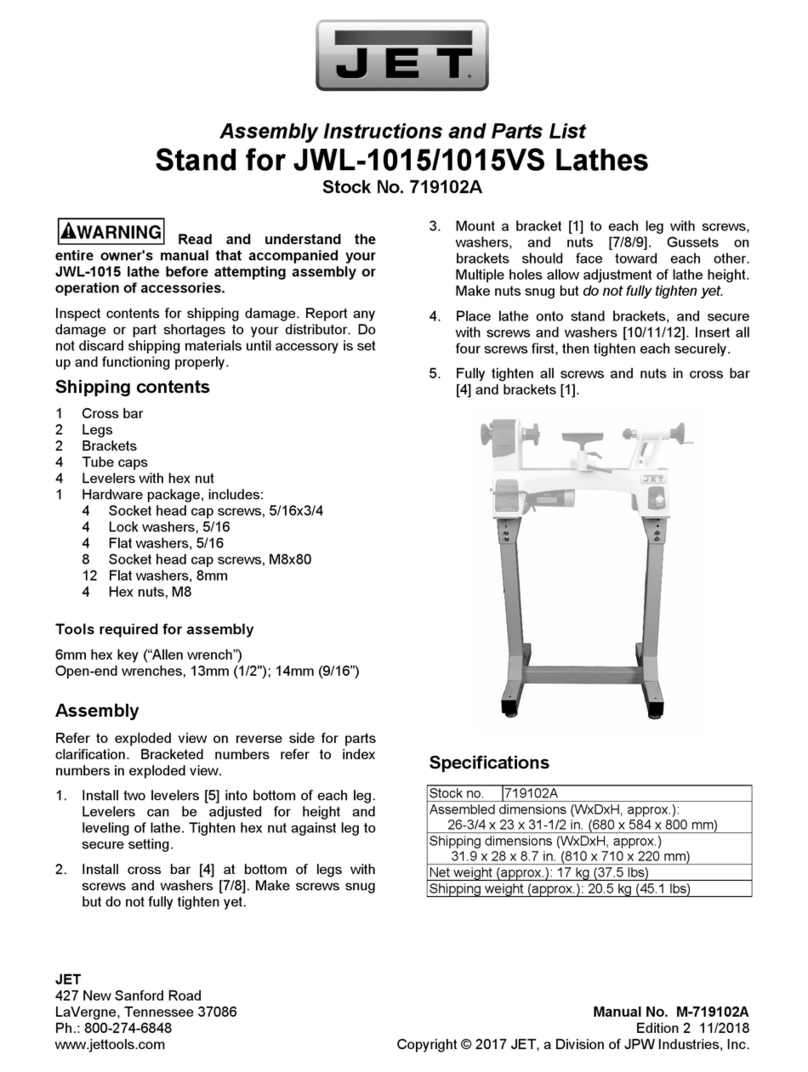

SECTION 3: SETUP ....................................... 11

SECTION 4: OPERATIONS ........................... 20