Power Fist 8942724 User manual

V1.0 8942724

Please read and understand all instructions before use. Retain this manual for future

reference.

8942724 12V DC Winch V1.0

2 For technical questions call 1-800-665-8685

SPECIFICATIONS

Voltage Rating 12V DC

Current Rating 360A

Single Rated Line Pull 12,000 lb

Cable Diameter 3/8 in.

Cable Length 65 ft

HP Rating 7 HP

Gear Ratio 232 : 1

Gear Type 3-stage planetary

Motor Type SW-4P

Braking Automatic load holding

Control Type Wired remote control

Fairlead Hawse Fairlead

Clutch Type Cam-activated free spooling

Full Load Line Speed 5 FPM

No Load Line Speed 22 FPM

Gear Train 3-stage planetary

Cable Material Oxygen free copper

Colour/Finish Powder coating

Mounting Bolt Pattern 10 x 4-1/2 in.

Size (L x W x H) 24.4 x 7.5 x 15.8 in.

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 3

INTRODUCTION

The 12V DC Electric Winch is strong enough for use in a shop or garage to pull

vehicles onto a lift or frame straightener. The unit has a tethered remote, overload

protection to avoid heat damage and a 65 ft steel cable with a sling hook.

SAFETY

WARNING! Read and understand all instructions before using this tool. The

operator must follow basic precautions to reduce the risk of personal injury

and/or damage to the equipment.

Keep this manual for safety warnings, precautions, operating or inspection and

maintenance instructions.

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A notice

is an alert that there is a possibility of property damage, injury or death if certain

instructions are not followed.

DANGER! This notice indicates an immediate and specific hazard that will

result in severe personal injury or death if the proper

precautions are not taken.

WARNING! This notice indicates a specific hazard or unsafe practice that

could result in severe personal injury or death if the proper

precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that may

result in minor or moderate injury if proper practices are not

taken.

NOTICE! This notice indicates that a specific hazard or unsafe practice will

result in equipment or property damage, but not personal injury.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean, well-lit

and free of distractions. Place lights so you are not working in a shadow.

2. Keep anyone not wearing the appropriate safety equipment away from the

work area.

3. Store tools properly in a safe and dry location. Keep tools out of the reach

of children.

4. Do not install or use in the presence of flammable gases, dust or liquids.

8942724 12V DC Winch V1.0

4 For technical questions call 1-800-665-8685

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the Canadian

Standards Association (CSA) or American National Standards Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side protection

for the eyes. Eye protection equipment should comply with CSA Z94.3-07

or ANSI Z87.1 standards based on the type of work performed.

2. Wear gloves that provide protection based on the work materials or to

reduce the effects of tool vibration.

a. Do not wear gloves when operating a tool that can snag the material

and pull the hand into the tool.

3. Wear protective clothing designed for the work environment and tool.

4. Non-skid footwear is recommended to maintain footing and balance in the

work environment.

5. Wear steel toe footwear or steel toe caps to prevent a foot injury from

falling objects.

PERSONAL PRECAUTIONS

Control the tool, personal movement and the work environment to avoid

personal injury or damage to the tool.

1. Do not operate any tool when tired or under the influence of drugs,

alcohol or medications.

2. Avoid wearing clothes or jewelry that can become entangled with the

moving parts of a tool. Keep long hair covered or bound.

3. Do not overreach when operating the tool. Proper footing and balance

enables better control in unexpected situations.

SPECIFIC SAFETY PRECAUTIONS

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use this

tool unsafely or incorrectly, you can suffer serious personal injury.

1. Use the correct tool for the job. This tool was designed for a specific

function. Do not modify or alter this tool or use it for an unintended

purpose.

2. Do not use the tool if any parts are damaged, broken or misplaced. Repair

or replace the parts.

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 5

3. All users must understand the operation of all controls and learn how to

stop the winch quickly in case of emergency.

4. Keep hands clear of the winch and steel cable when spooling the line in or

out. Hold the cable by the strap. Fingers caught in the hook or fairlead

may be pulled into the mechanism and crushed or pinched.

5. Make sure the winch is fixed to a solid support structure that can

withstand the towing capacity.

6. Never fully extend the cable while under load.

7. Do not exceed the winch load capacity.

a. Do not use the winch if damaged or it was subjected to a dynamic

shock load. Have the winch inspected and repaired by a qualified

service technician.

8. Always use proper couplings when connecting the winch cable hook,

sling, eyebolt or other accessory to the load. Never connect the hook back

to the cable. This causes cable damage. Always use a sling or chain of

suitable strength.

9. Do not use inappropriate attachments to extend the length of the winch

cable.

10. Do not lift items vertically. The winch was designed for horizontal use

only.

11. Do not pull the steel cable around or over corners.

12. Stay well away from the winch, steel cable and load when under tension.

A cable that breaks under tension can whiplash and inflict death or a

serious injury.

a. Use a winch rope dampener to absorb the cable’s energy should it

break.

13. Secure the load after moving it with the winch. Do not rely on the winch

to hold a load in position for an extended period of time. Never leave the

load unattended.

14. Apply blocks to a vehicle while connecting and disconnecting the winch

cable.

15. Observe the spooling of the cable onto the drum. Side pulls can cause the

cable to pileup at one end of the drum. To correct uneven stacking, spool

out that section of cable and move it to the other end of the drum and

continue winching. Uneven spooling causing cable pileup can interfere

with the winch tie rods causing damage to the winch.

8942724 12V DC Winch V1.0

6 For technical questions call 1-800-665-8685

16. Do not use the winch to transport animals or people.

17. Do not use the vehicle to ‘assist’ the winch in moving a load. This applies

additional strain on the winch and can damage it or snap the winch cable.

ELECTRICAL SAFETY

WARNING! Do not touch or handle a live tool with any part of your body that is

wet or damp. Wet skin reduces resistance to electrical current, increasing the

danger of a serious or fatal shock.

1. Disconnect tool from power source before cleaning, servicing, changing

parts/accessories or when not in use.

2. Protect yourself against electric shocks when working on electrical

equipment. Avoid body contact with grounded surfaces. There is an

increased chance of electrical shock if your body is grounded.

3. Do not expose the tool to rain or wet conditions. Water entering a tool will

increase the risk of electric shock.

4. Do not alter any parts of the tool or accessories. All parts and accessories

are designed with built-in safety features that may be compromised if

altered.

5. Make certain the power source conforms to requirements of your

equipment (see Specifications).

6. When wiring an electrically driven device, follow all electrical and safety

codes, as well as the most recent Canadian Electrical Code (CE) and

Canadian Centre for Occupational Health and Safety (CCOHS).

7. Disconnect the battery cables before working near the cable, drum,

fairlead or load, to prevent accidental starting.

WARNING! All wiring should be performed by a qualified electrician.

BATTERY CABLES

1. Do not operate this tool if the battery cables are frayed or damaged, as an

electric shock or surge may occur, resulting in personal injury or property

damage.

2. Keep all connections dry and off the ground to reduce the risk of electric

shock. Do not touch battery cables with wet hands.

3. Prevent damage to the battery cables by observing the following:

a. Do not pull on the cable to disconnect it from the battery

b. Keep the battery cables away from heat, oil, sharp edges or moving parts.

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 7

UNPACKING

WARNING! Do not operate the tool if any part is missing. Replace the missing

part before operating. Failure to do so could result in a malfunction and

personal injury.

Remove the parts and accessories from the packaging and inspect for damage. Make

sure that all items in the contents are included.

Contents: • Winch • Tethered Remote • Hawse Fairlead

• Hook with Strap • Grade 8, M10-1.50x30 mm (4)

• Grade 8 M12-1.75x25 mm

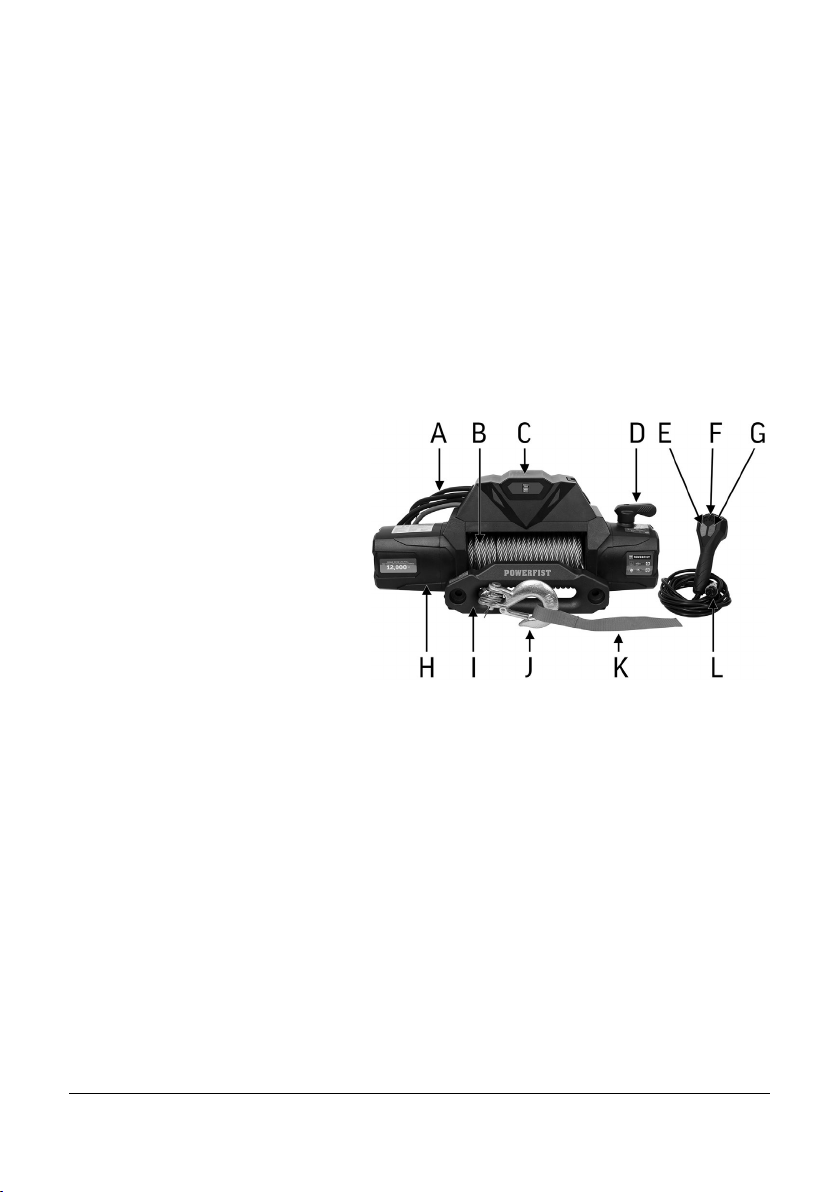

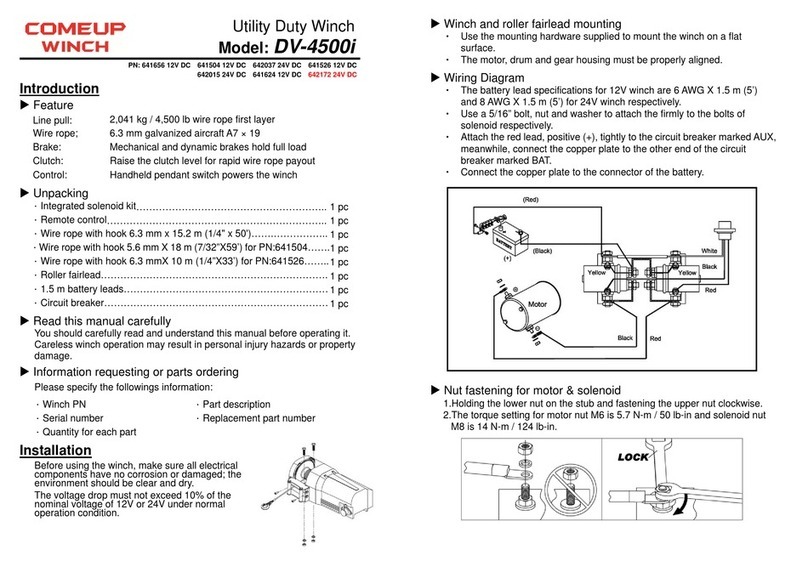

IDENTIFICATION KEY

A Wiring

B Wire Cable

C Control Pack

D Clutch

E IN Button

F Remote

G OUT Button

H Winch

I Hawse Fairlead

J Hook

K Strap

ASSEMBLY & INSTALLATION

Use the included hardware to attach the winch to the location and the fairway

to the winch.

1. Install a mounting plate that is capable of withstanding the stresses

acting upon it without bending or breaking (see Specifications). The drum

supports must sit flush with no gaps.

2. This winch can generate extreme

forces

.

Select

a location that can

withstand the rated capacity

without

damage or weakening. Steel

reinforcement plates may be needed or a certified welder may need to

weld

on

additional bracing depending on the mounting location.

Fig.

1

8942724 12V DC Winch V1.0

8 For technical questions call 1-800-665-8685

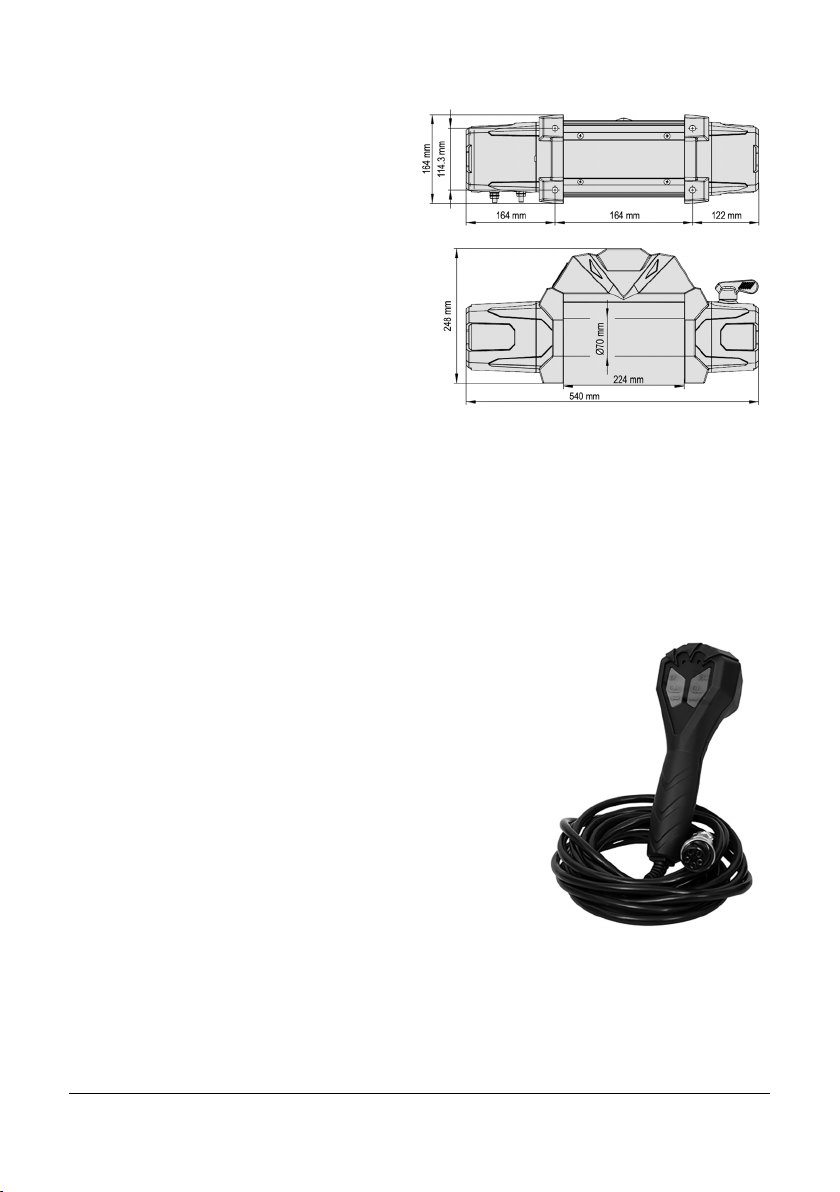

3. Align the winch perpendicular to

the vehicle’s centerline of

the

vehicle at the desired

location.

Mark the bolt holes you will use

to connect the winch to the

structure. Compare the

dimensions

of the marked

holes.

4. Before drilling, verify that the

installation surface has no

hidden components

or

structural pieces that will be

damaged.

5. Drill holes for the

hardware

at

the marked

locations.

6. Install the winch using the included

hardware

. Do not weld the mounting

bolts in place.

OPERATION

REMOTE

1. Press the IN button. The red LED above the

button will glow and the cable will retract into

the drum.

2. Press the OUT button. The green LED above the

button will glow and the cable will spool out.

3. There is a slight delay when switching from

one direction to the other.

4. Both LEDs will flash when the battery voltage

is below 10.8V. The battery requires recharging

or replacement.

5. The winch may stall at the maximum load (see

Specifications). Winch protection will activate

after two seconds and both LEDs will flash.

BEFORE FIRST USE

The steel cable must be broken-in before using to pull a heavy load. The break-

in process will stretch the cable, ensure the individual wires are seated and the

wire compacted.

Fig. 2

Fig.

3

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 9

1. Position the vehicle on a flat surface approximately 60 ft distance from a

suitable anchor point, such as a large tree.

2. Unspool the entire cable until only five cable wraps are remaining on the

winch drum.

a. Remove the entire cable if the remaining wraps are overlapping or

there is a gap that the second level of cable can become trapped in.

Rewrap the five wraps carefully without load.

3. Attach a chain or belt around the anchor point that is capable of

withstanding the load. Connect the cable hook to the chain or belt.

4. Shift the vehicle into neutral gear to prevent damage to the transmission.

5. Follow the instructions in Operating The Winch and recoil the rope back

into the winch under at least 1,000 lb (454 kg) of tension. Apply light

pressure to vehicle brake pedal as needed to produce load.

6. Stop approximately every minute to check that the cable is winding level.

Make sure vehicle is in park with parking brake applied before exiting the

vehicle. Do not check, touch or attempt to reposition rope with load on

winch rope.

OPERATING THE WINCH

WARNING! Do not release the clutch while the winch is pulling a load. It may

cause the load to shift or move unexpectedly and the wire may snap with the

unexpected stress. Either may cause death or severe injury to the user or

bystanders.

WARNING! Keep clear of fairlead when operating. Do not try to guide the wire

rope, as your hand may be pulled into the winch and suffer a crushing injury.

Do not operate the winch on slopes. The cable angle should be as close to

vehicle center line as possible.

1. Make sure the operator can safely

control the winch before performing

any functions with it and that they

are familiar with all safety and

operating instructions.

2. Inspect the winch, steel cable and

terminal tackle before each use.

Replace any damaged or frayed

components before use.

Fig. 4

8942724 12V DC Winch V1.0

10 For technical questions call 1-800-665-8685

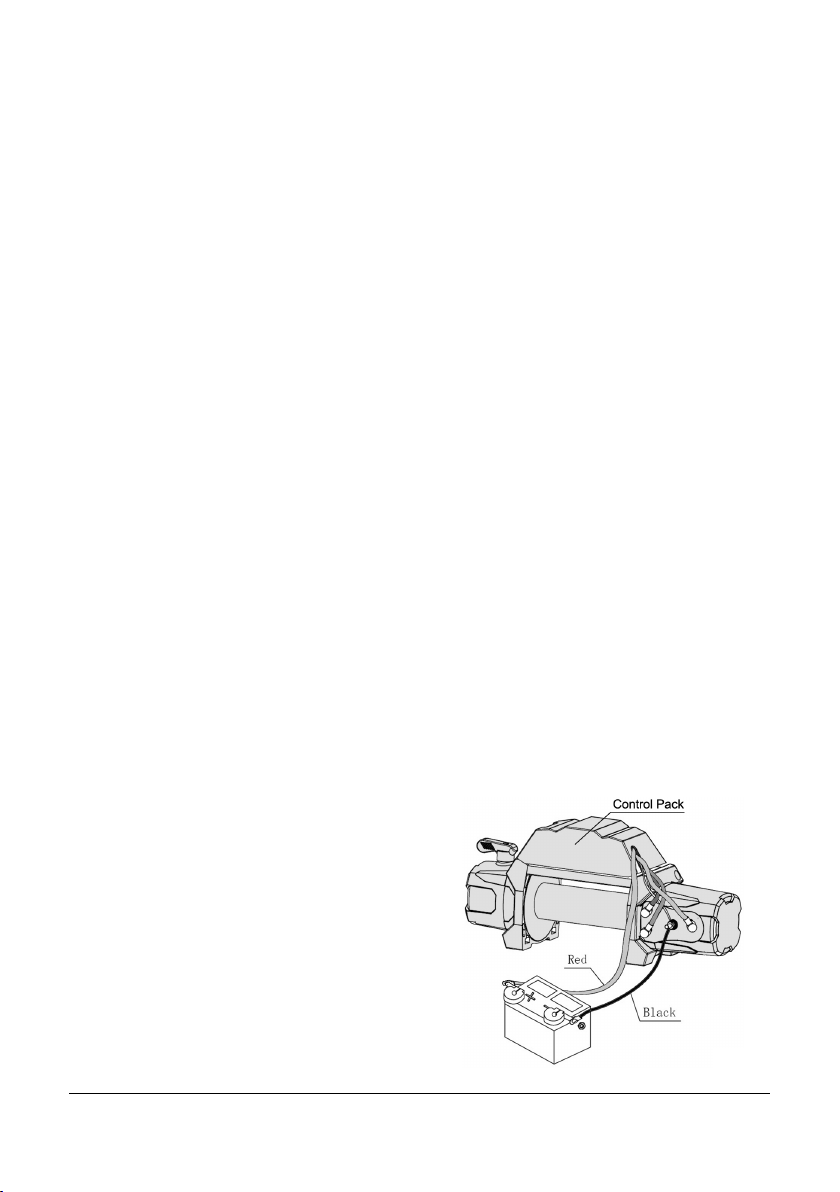

3. Connect the winch to a 12V power supply. The

12V automotive battery must be in good

operating condition. Consult the battery’s

safety and use instructions (Fig. 4).

a. Attach the red battery cable to the

positive battery terminal.

b. Attach the black battery cable to the

negative battery terminal

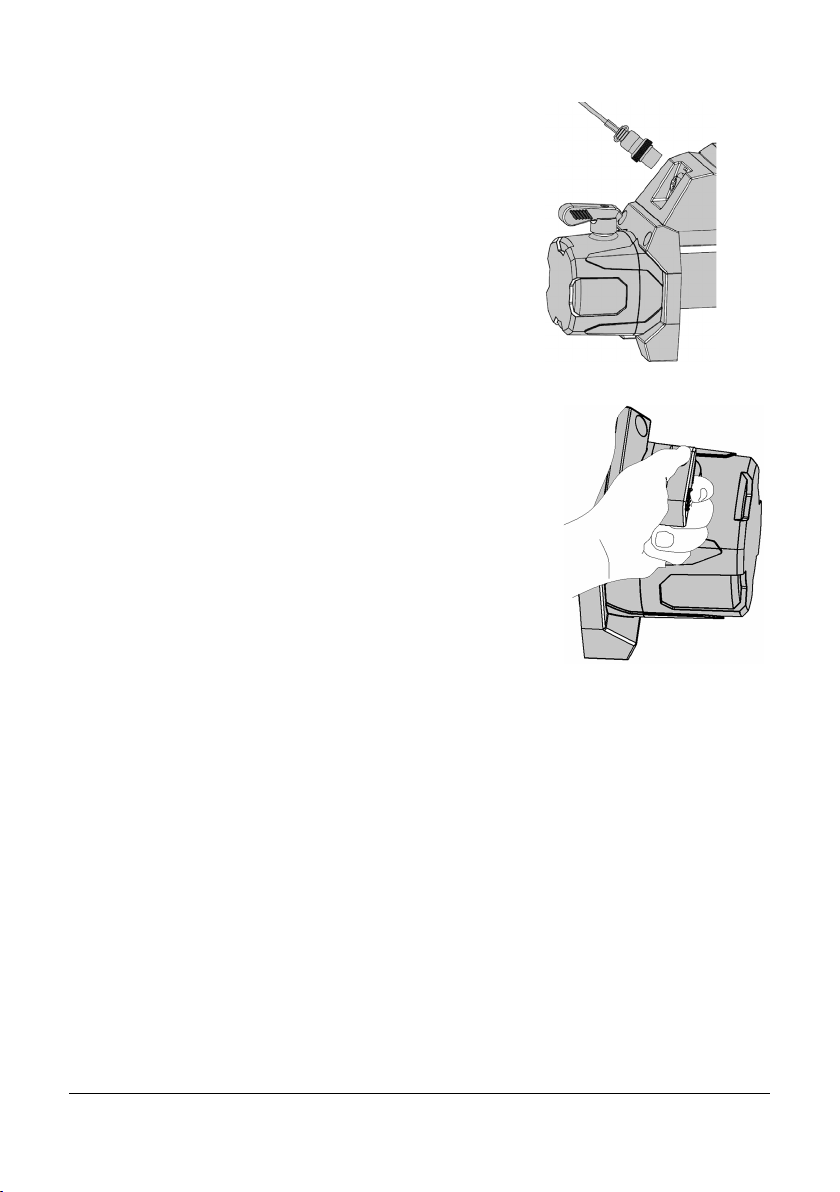

4. Insert the remote control plug into the winch

(Fig. 5). Press both the IN and OUT buttons to

make sure they winch is functioning properly.

5. Twist the clutch knob out a quarter turn to the

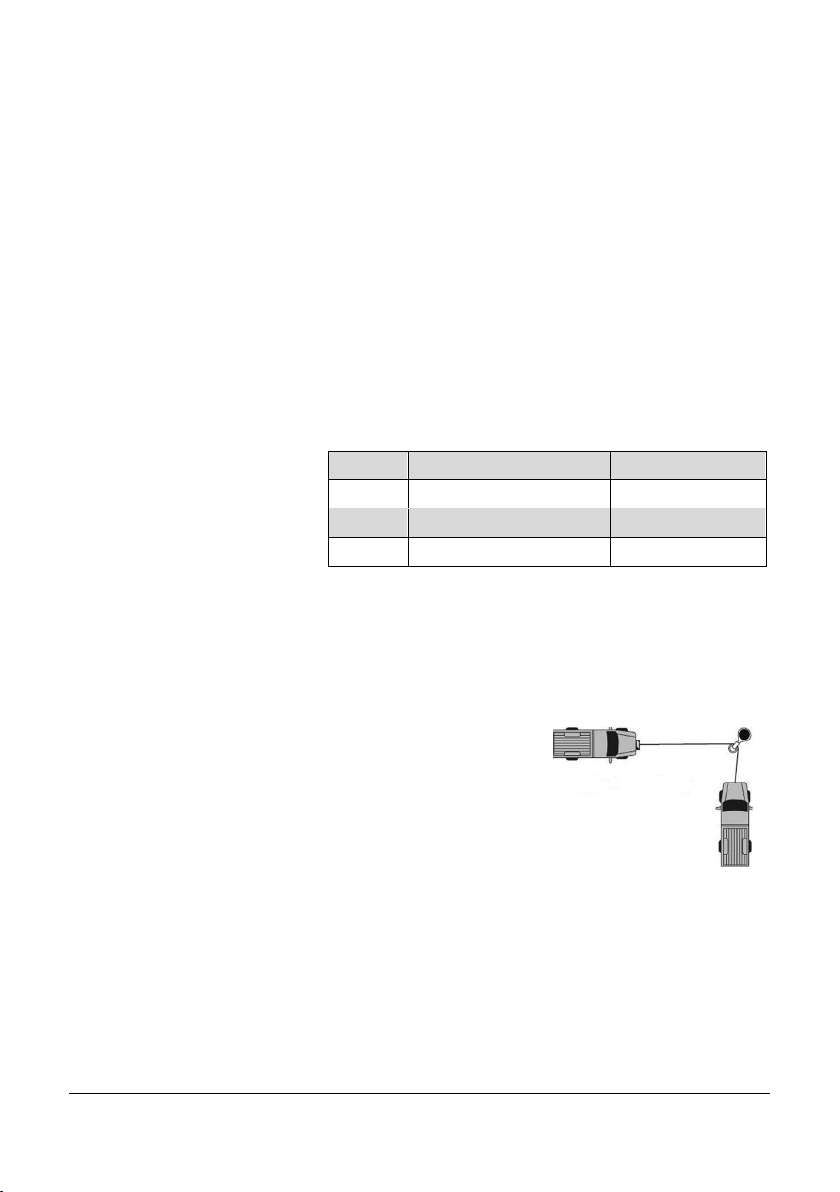

left to disengage the brake (Fig. 6).

6. Pull out the cable by the hook strap until you

have the desired length out.

a. Make sure there is always five turns of

cable on the winch drum.

7. Attach the steel cable to the load with a hook,

shackle, sling or chain capable of withstanding the

strain from winching the load. Make sure the

terminal tackle is secure to avoid an unintended

disconnection while winching.

a. Consult the vehicle owner’s manual for anchor points to connect the

steel cable’s terminal tackle if connecting to another vehicle.

8. Re-engage the clutch by twisting the clutch knob to the right until it locks

in place.

9. Check that the line is straight without kinks or twisted. Do not wrap the

steel cable around the load or wind it around corners or obstacles.

10. Place a dampening device on the steel cable, if you have one available.

11. Press and hold the remote control’s IN button until the slack is removed

from the steel cable.

12. Recheck the connections to ensure the terminal tackle will not shift.

a. Check the clutch is engaged. Do not pull the clutch knob out when

the winch is under load.

13. Press and hold the remote control’s IN button to pull the load towards the

winch. Release the button when the load is in the final position.

a. Secure the load in place if necessary. Use wheel chocks for a vehicle.

Fig. 6

Fig. 5

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 11

14. Press the Out button to remove tension on the steel cable. Disengage and

remove the hook or terminal tackle.

15. Hold the hook strap to keep some pressure on the winch and retract the

steel cable. Make sure each wire wrap fits snugly with the next wrap.

16. Disconnect from the power supply once the hook reaches the winch fairlead.

17. Disconnect and store the remote.

WINCHING LIMITATIONS

There are several limitation that can affect the time duration, power consumption

and maximum weight a winch can move. A snatch block will improve the winch’s

performance. Make sure to follow all safety and operation instructions from the

snatch block’s manufacturer.

POWER

The maximum load the

winch can pull is

diminished with each

additional layer of steel

cable around the winch’s

drum. Table 1 shows the

maximum amount of

weight it can pull and the length of cable remaining on the drum.

Whenever possible, remove as much steel cable off the winch to pull with the

maximum power. Keep five wraps of steel cable on the drum at all times to

prevent the steel cable from slipping off.

Use a snatch block to move a heavier load that is

close to the winch. This will double the amount of

line outside the fairlead and increase the winch’s

pulling power at close range.

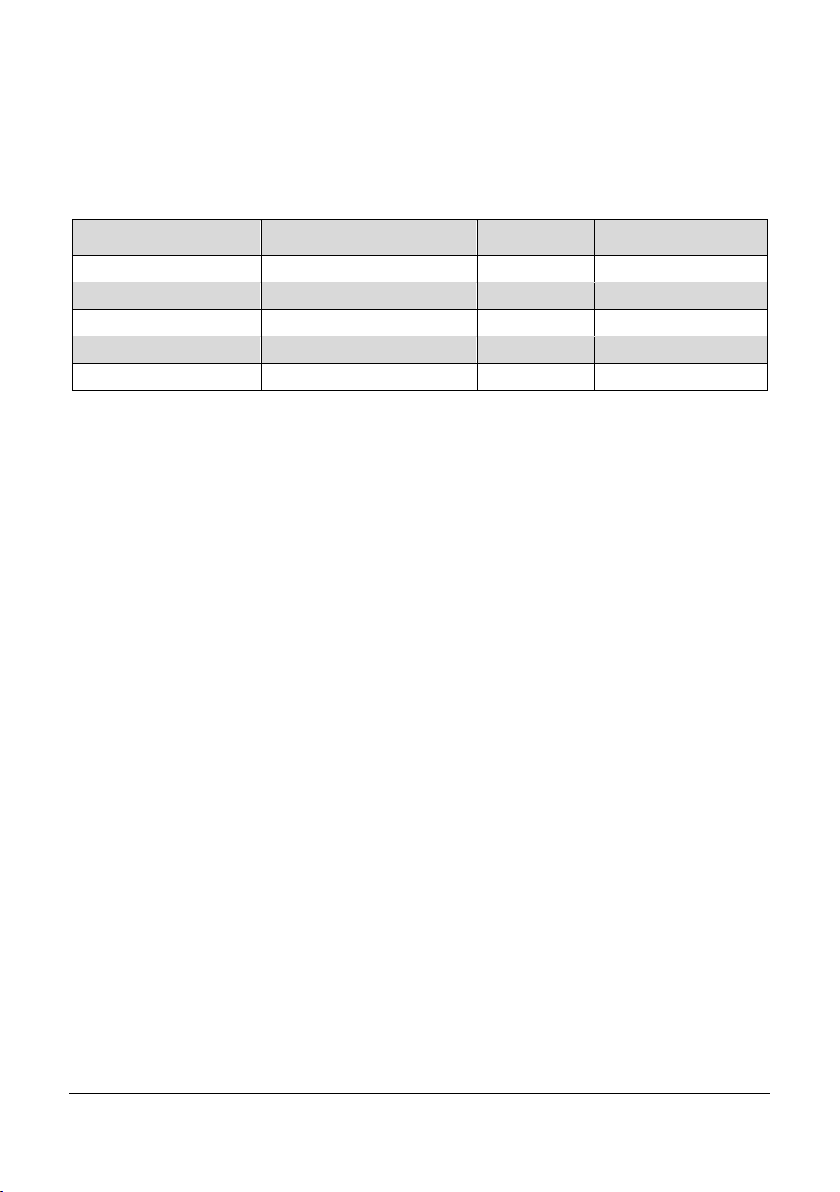

Pull a load at an angle by using a pulley attached to

a structure (Fig. 7). Both must be capable of

withstanding the load.

LINE SPEED

The heavier the load, the longer it will take the winch to move the load to the

desired location. Consult Table 2 to determine how fast the line will be drawn

into the winch.

A snatch block will halve the line speed when pulling the load.

Layer Rated Line Pull Cable Capacity

1 12,000 lb (5,443 kg) 17 ft (5.2 m)

2 9,685 lb (4,393 kg) 40 ft (12.2 m)

3 8,119 lb (3,683 kg) 65 ft (20 m)

Table 1

Fig. 7

8942724 12V DC Winch V1.0

12 For technical questions call 1-800-665-8685

POWER CONSUMPTION

The winch requires more amps to move a heavier load. Consult Table 2 to

determine the amperage consumption based on the load’s weight.

A snatch block increases a winch’s pulling power without an increase in amperage.

Using a snatch block can halve the power required.

OVERLOAD

The overload protection may kick in if the winch becomes overheated. Allow

several minutes for the winch to cool before pressing the overload reset button

to continue pulling the load.

NOTICE! Do not press and hold the reset button while winching. This can

damage the winch.

CARE & MAINTENANCE

1. Maintain the tool with care. A tool in good condition is efficient, easier to

control and will have fewer problems.

2. Inspect the tool components periodically. Repair or replace damaged or

worn components. Only use identical replacement parts when servicing.

3. Follow instructions for lubricating and changing accessories.

4. Only use accessories intended for use with this tool.

5. Keep the tool handles clean, dry and free from oil/grease at all times.

6. Maintain the tool’s labels and name plates. These carry important

information. If unreadable or missing, contact Princess Auto Ltd. for

replacements.

WARNING! Only qualified service personnel should repair the tool. An

improperly repaired tool may present a hazard to the user and/or others.

CLEANING

Clean the external surfaces with cloth after each use.

Weight Pull Line Speed Amp Draw Max Pull Length

0 lb (0 kg) 21 FPM (6.4 m/min) 80 VDC 65 ft (20.0 m)

3,000 lb (1,361 kg) 11 FPM (3.4 m/min) 160 VDC 20 ft (6.1 m)

6,000 lb (2,722 kg) 8 FPM (2.4 m/min) 260 VDC 8 ft (2.4 m)

9,000 lb (4,082 kg) 6 FPM (1.8 m/min) 280 VDC 3 ft (1.0 m)

12,000 lb (5,443 kg) 5 FPM (1.5 m/min) 360 VDC 1 ft (0.3 m)

Table 2

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 13

LUBRICATION

The winch is permanently lubricated and does not require additional

lubrication. The exception is if the winch is submerged in water. Open the

housing, dry and have a qualified technician re-lubricate the winch.

Lubricate the steel cable with a light oil from time to time to prevent corrosion.

STORAGE

When not in use for an extended period, apply a thin coat of lubricant to the

steel parts to avoid rust. Remove the lubricant before using the tool again.

DISPOSAL

Recycle a tool damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for

electronic devices, batteries, oil or other toxic liquids.

IMPORTANT! DO NOT pollute the environment by allowing uncontrolled

discharge of waste oil.

TROUBLESHOOTING

Visit a Princess Auto Ltd. location for a solution if the tool does not function

properly or parts are missing. If unable to do so, have a qualified technician

service the tool.

Problem(s) Possible Cause(s) Suggested Solution(s)

Motor overheats. Winch running time too

long.

Allow winch to cool down

periodically.

Motor does not

turn on.

1. Solenoid malfunctioning.

2. Remote damaged.

3. Defective motor.

4. Internal damage or

wear.

5. Remote not properly

plugged in.

6. Battery cables damaged

or not properly

connected.

1. Tap solenoid to loosen contacts.

2. Replace remote.

3. Check for voltage at armature

port with switch pressed. If

voltage is present, replace motor.

4. Have technician service winch.

5. Check the remote plug is firmly

seated.

6. Replace damaged cables or

reconnect clips to the battery.

Motor runs, but

steel cable

drum does not

turn.

The clutch is not engaged. Move the clutch handle to the

engaged position. If problem

persists, a qualified technician

needs to check and repair.

8942724 12V DC Winch V1.0

14 For technical questions call 1-800-665-8685

Problem(s) Possible Cause(s) Suggested Solution(s)

Motor runs slowly

or without normal

power.

Insufficient current or

voltage.

Connect to appropriate power supply.

Motor runs in one

direction only.

1. Defective or stuck

solenoid.

2. Remote damaged.

3. Defective remote

button.

1. a. Tap solenoid to loosen contacts.

1. b Repair or replace solenoid.

2 & 3 Replace remote.

Motor is water

damaged.

Submerged in water or

water from pressure

washing.

Allow to drain and dry thoroughly.

Have a service technician repair

and lubricate the winch.

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 15

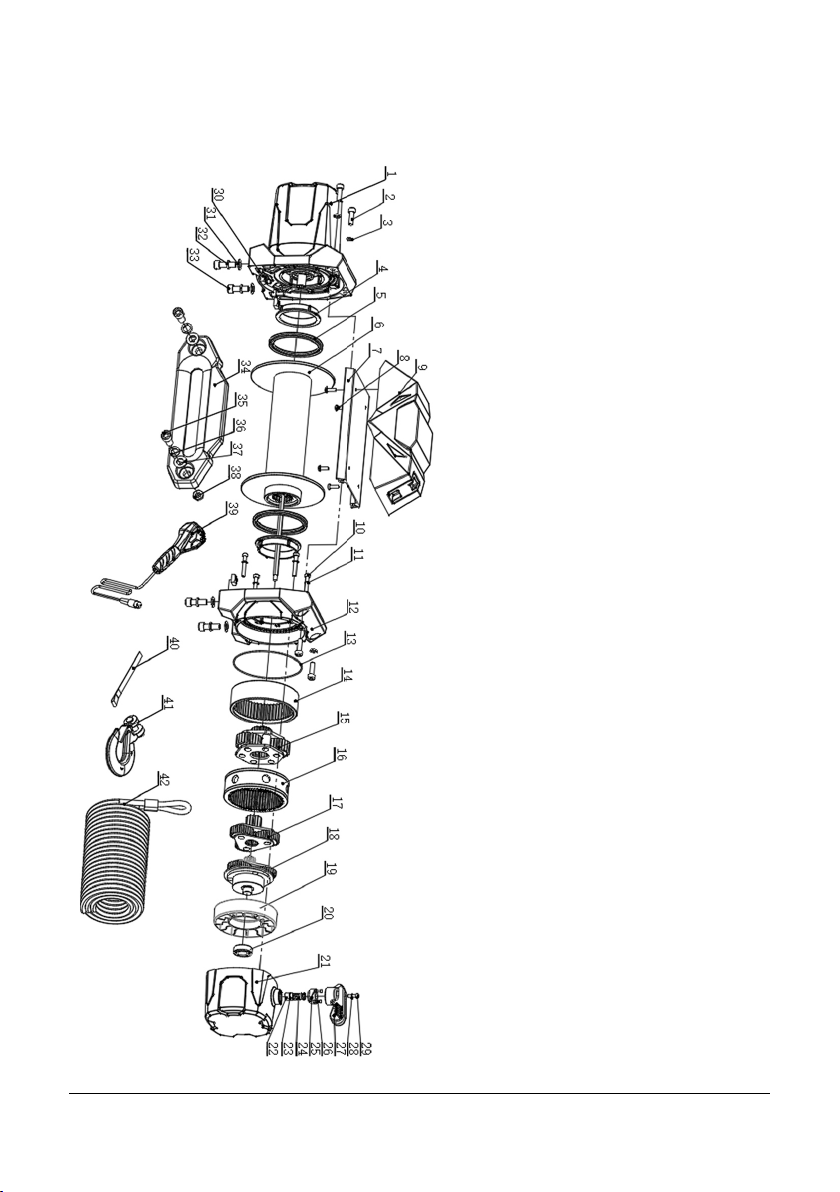

PARTS BREAKDOWN

8942724 12V DC Winch V1.0

16 For technical questions call 1-800-665-8685

PARTS LIST

#

DESCRIPTION

QTY

1 Motor Assembly 1

2 Tie Bar Screw M8x30 4

3 Tie Bar Washer Ø8 4

4 Nylon Bearing 2

5 Seal Kit 2

6 Drum Assembly 1

7 Support Plate 1

8 Cross Recessed Pan Head Ta

pping Screws ST5.5 x16

4

9 Integrated Control Pack 1

10 Tie Bar Screw M6x50 4

11 Tie Bar Washer Ø6 4

12 Gear Box Base 1

13 O-Ring 125x2 1

14 3 Stage Ring Gear 1

15 Gear Carrier Assembly

(Output)

1

16 Clutch Gear 1

17 Gear Carrier Assembly

(Intermediate)

1

18 Gear Carrier Assembly

(Input)

1

19 Baffle Plate 1

20

Bearing

1

21 Deceleration Box 1

22

Clutch Pin

1

23 O-Ring 10.6 x1.8 1

24

Clutch Spring

1

25 Clutch Cap 1

26

Tie Bar Screw M3x16

1

27 Clutch Handle 1

28

Tie Bar Screw M5x14

1

29 Tie Bar Washer Ø5 1

30

Square Nut M10

4

31 Flat Washer Ø10 4

32

Spring Washer Ø10

4

33 Tie Bar Screw M10x30 4

34

Hawse Fairlead

1

35 Tie Bar Screw M12x25 2

36

Spring Washer Ø12

2

37 Flat Washer Ø12 2

38

Nut M12

2

39 Pendant Controller 1

40

Red Strap

1

41 Clevis Hook 1

42

Wire cable

1

V1.0 12V DC Winch 8942724

Visit www.princessauto.com for more information 17

8942724 12V DC Winch V1.0

18 For technical questions call 1-800-665-8685

V 1,0 8942724

Vous devez lire et comprendre toutes les instructions avant d'utiliser l'appareil.

Conservez ce manuel afin de pouvoir le consulter plus tard.

8942724 Treuil, 12 Vcc V 1,0

2 En cas de questions techniques, appelez le 1-800-665-8685

SPÉCIFICATIONS

Tension nominale 12 Vcc

Courant nominal 360A

Traction linéaire nominale simple 12 000 lb

Diamètre de câble 3/8 po

Longueur de câble 65 pi

Puissance nominale en CV 7 CV

Rapport d’engrenage 232 : 1

Type d’engrenage Planétaire à 3 étages

Type de moteur SW-4P

Freinage Rétention de charge automatique

Type de commande Télécommande à fil

Guide-câble Guide-câble d’écubier

Type d’embrayage Décrabotage à commande par came

Vitesse linéaire à la charge maximale 5 pi/min

Vitesse linéaire à vide 22 pi/min

Train d’engrenages Planétaire à 3 étages

Matériau de câble Cuivre sans oxygène

Couleur/fini Revêtement en poudre

Disposition des boulons de montage 10 x 4 1/2 po

Taille (long. x larg. x haut.) 24,4 x 7,5 x 15,8 po

Table of contents

Languages:

Other Power Fist Winch manuals

Popular Winch manuals by other brands

Lewmar

Lewmar 40 manual

Kangaroowinch

Kangaroowinch 2000 instruction manual

Harken

Harken Performa 46.2 STP Installation and maintenance manual

Prowinch

Prowinch PWMD Series User Manual and Security Warnings

Badland

Badland 56412 Owner's manual & safety instructions

WOODY'S WINCH

WOODY'S WINCH WW-700-34 manual

TORSO WINCH

TORSO WINCH HC0200E Installation and operating instructions

KStrong

KStrong AFA930301 User instruction manual

Harken Industrial

Harken Industrial 500 installation manual

Tractel Group

Tractel Group altotir Operating and maintenance instructions

Comeup

Comeup Rhino 12 Pro manual

Comeup

Comeup DV-4500i quick start guide