Harken Industrial 500 User manual

Please read these instructions carefully before installing, servicing, or operating the equipment.

This manual may be modified without notice. In the event of this manual being translated, the English version is definitive. For latest

manual revision go to www.harkenindustrial.com/manuals

PLEASE SAVE THESE INSTRUCTIONS

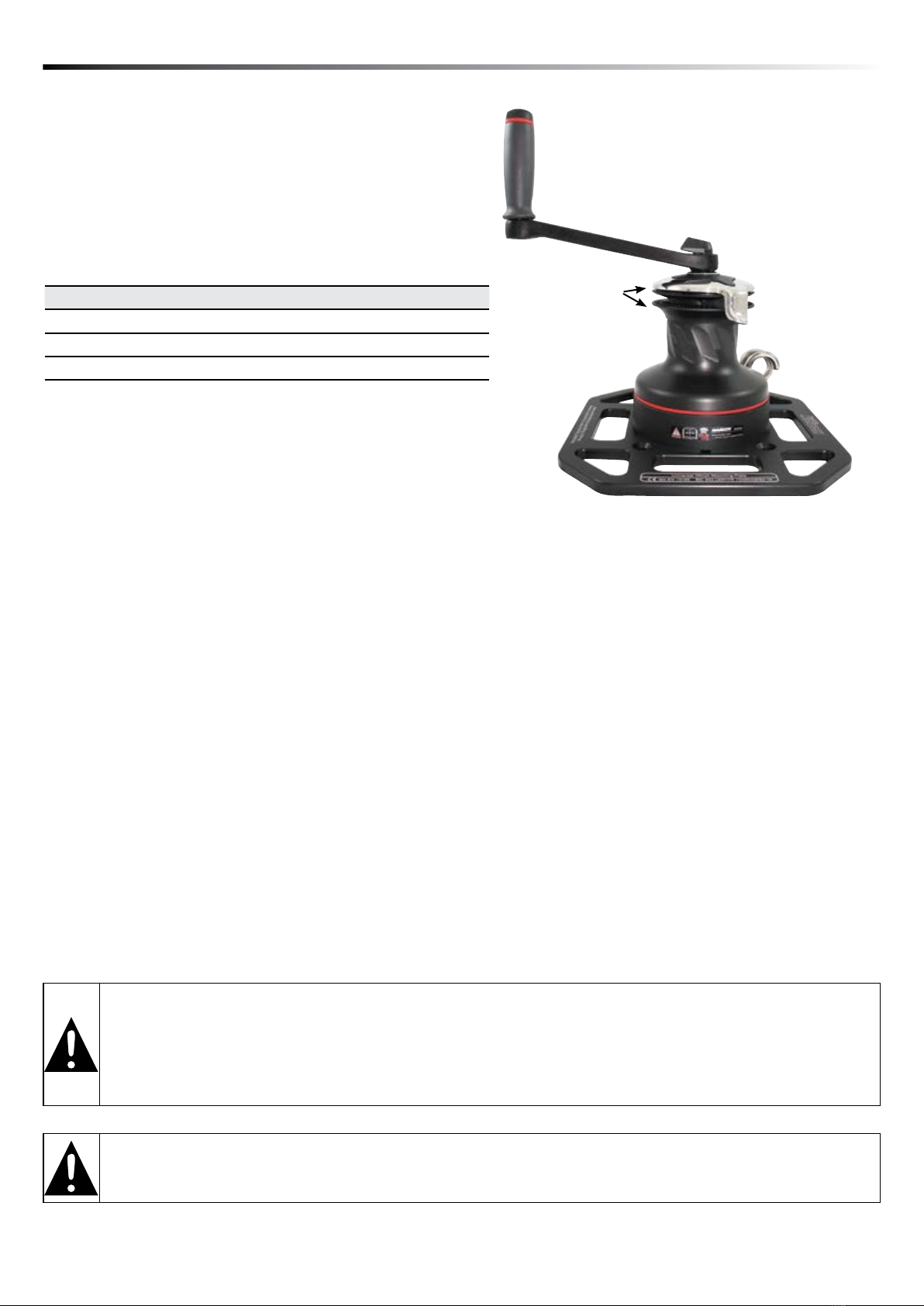

RIGGERS WINCH 500

Installation Manual – Intended for specialized personnel or expert users

INRW500_A 03/19

Introduction

Safety Precautions 3

Applications/Limitations 4

Specification 5

Installation

Plan Installation 6

Pre-Use Checks 7

Operation

Lifting Loads 8

Lowering Loads 9

Maintenance

Inspection 10

Maintenance 10

Disassembly 11-13

Cleaning 14

Assembly 15-17

Declaration of Conformity 18

Parts

Exploded View 19-20

Parts List 21-22

2 Riggers Winch 500 01/03/19

3 Riggers Winch 500 01/03/19

Safety Precautions

Please read these instructions carefully before operating equipment.

Keep these instructions in a safe place for future reference.

i

This product, as supplied by Harken®, is considered to be applicable to general lifting operations.

Should this product be incorporated into systems for lifting persons, it becomes “partly completed

machinery” and, when appropriate additional safety devices are added, must be certified for its

intended application. Such systems are classified as “machinery for lifting persons” and would

require separate CE marking.

Service Manual

You can download the Service Manual from www.harkenindustrial.com/manuals. This manual is for use only by

specialized personnel. Installation, disassembling and reassembling by personnel who are not experts may cause serious

damage to property or injury to users and those in the vicinity of the product. Harken®accepts no responsibility for

damage or harm caused by not observing the safety requirements and instructions in the service manual. See limited

warranty, general warnings, and instructions at www.harkenindustrial.com/manuals.

Introduction

This manual gives technical information on installation and service. If you do not understand an instruction, contact

Harken®.

WARNING! Strictly follow all instructions to avoid potential hazards that may kill or hurt you and others.

See www.harkenindustrial.com/manuals for general warnings and instructions.

DANGER! This indication alerts you to imminent hazards that will kill or seriously injure you and others

if you don't follow instructions. The message will tell you how to reduce the chance of injury.

WARNING! This indication alerts you to potential hazards that may kill or seriously injure you and others

if you don't follow instructions. The message will tell you how to reduce the chance of injury.

CAUTION! This indication alerts you to potential hazards that may hurt you and others if you do not fol-

low instructions. The message will tell you how to reduce the chance of injury.

4 Riggers Winch 500 01/03/19

Applications/Limitations

WARNING! Subjecting the winch to loads above the maximum working load can cause the winch to

fail or pull off the mounting surface suddenly, possibly resulting in severe injury or death.

B. LIMITATIONS

DO NOT USE:

• With wire rope

• With loads in excess of the maximum working load of 500kg for lifting loads.

Self-Tailing

Stripper Arm

Handle

Winch

Drum

Self-Tailing

Jaws

Winch

Plate

Pigtail

A. USE

Harken®Riggers Winch 500 is designed to be used as a manually powered, rope-handling winch secured on a

universal mounting plate, for lifting, lowering and pulling loads.

C. TRAINING

This equipment must be installed and used by persons trained in its correct application and use.

D. STANDARDS

This product/system has been certified to EN13157 standards.

E. TESTING

Maximum working loads are 4:1 coefficient ratio of the breaking load.

Part No. Description Quantity

A96889400 Harken Radial Winch 1

F83256700 B10AL Harken Winch Handle (lock-in) 1

A96885400 Plate 1

WARNING! As reported in the Directive 2009/104/EC "Persons may be lifted only by means of work equipement and

accessories provided for that purpose. Without prejudice to Article 5 of Directive 89/391/EC, exceptionally, work equipment

which is not specifically designed for the purpose of lifting persons may be used for that purpose, provided appropriate

action has been taken to ensure safety in accordance with national legislation and/or practice providing for appropriate

supervision" .

CONTENTS SUPPLIED

5 Riggers Winch 500 01/03/19

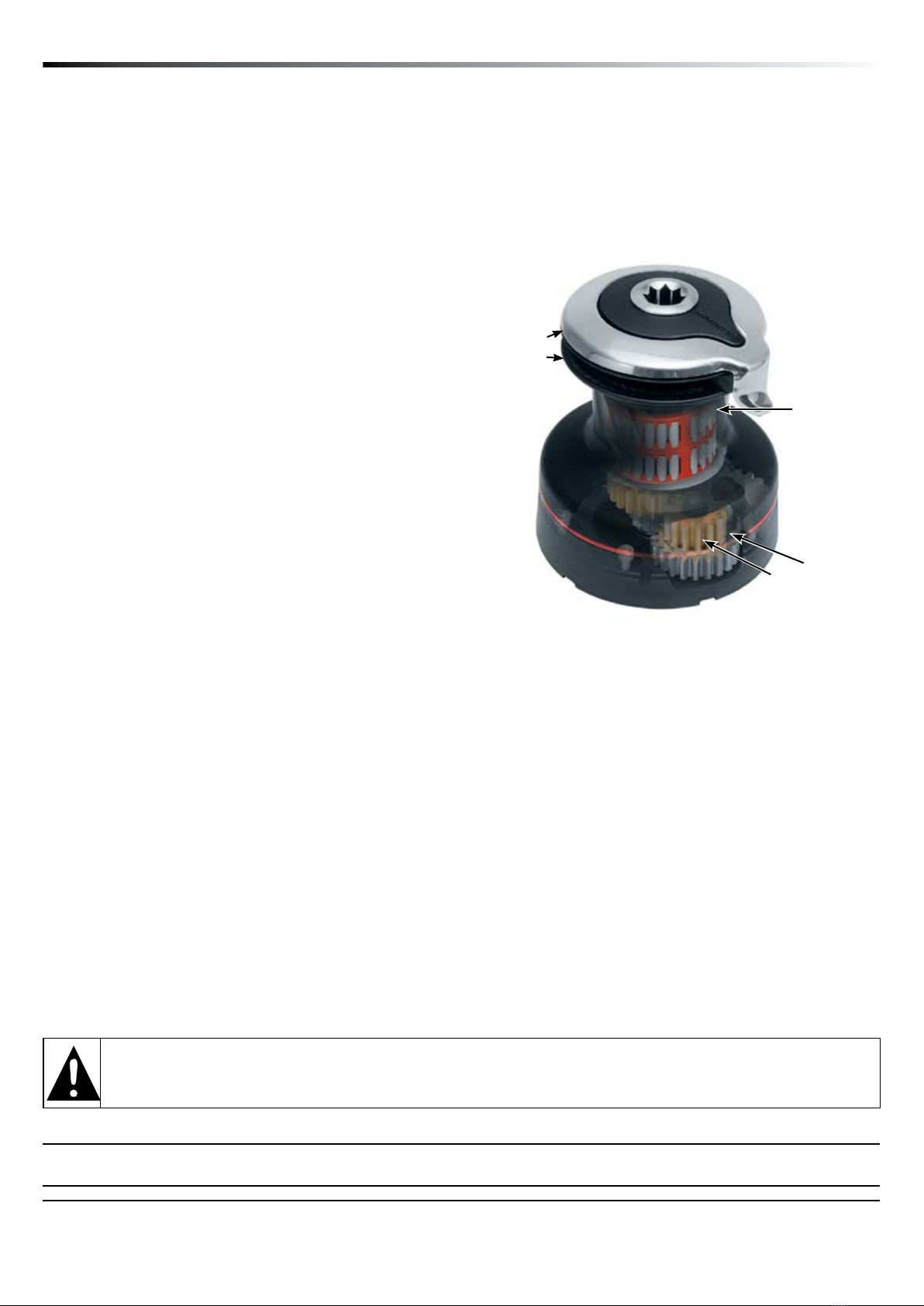

Self-Tailing

Stripper Arm

Hardcoat, PTFE-

Impregnated

Aluminum Drum

and Castle

Bronze and Stainless

Steel Gears

Composite

Bearings

Self-Tailing

Jaws

Part

No.

Ø

Height (H) Weight

Rope entry

height (LE)

Rope Ø

(Min - Max)

Fastener

circle

Fasteners

(HH) Gear ratio Power ratioDrum (D) Base (B)

in mm in mm in mm lb kg in mm in mm in mm mm 1 2 3 1 2 3

INRW500 3

1

/

8

80 6

3

/

16

157 6

7

/

8

175 8.4 3.8 3

1

/

4

82

5

/

16

-

1

/

2

8- 12 4

7

/

8

123 5 x 6 2.13 6.28 —13.50 39.90 —

FEATURES

Maximum Grip – The drum’s gripping surface is designed

specifically to work with the drum diameter and material to

maximize gripping power and reduce rope wear. Diagonal

ribs stop the rope from rising (keeping rope wraps on part

of drum where you have the best control), prevent

overrides, and provide a smooth controlled release as rope

exits the winch.

Spring-loaded, self-tailing jaws adjust under rope pressure

to accept a variety of rope diameters. Teeth grip evenly

with or without load.

Lightweight – overall weight only 7kg

Powerful – 2-speed gearing allows optimum use of

manpower to deliver power and speed.

Reliable & Easy to Maintain – Composite roller

bearings and bushings don’t require lubrication and have excellent corrosion resistance. This ‘metal-

replacement’ material is completely non-reactive to saltwater and most chemicals, and has very good wear

and abrasion resistance under maximum operating loads.

Load-carrying gears and pins are 17-4PH stainless steel for strength and durability.

Planetary gears are bronze to avoid stainless-on-stainless galling.

Winches can be disassembled and serviced where mounted.

Easy Line Control - Locking jaws hold loaded rope securely during operation and while suspended. The

stripper arm is shaped to smoothly feed the rope in and out of the jaws so the operator can use both hands

to turn the winch. The stripper arm adjusts to multiple positions after the winch is mounted so rope exit

position can be optimized.

SPECIFICATIONS

Maximum Working Load:

Winch: 500 kg

Break Load: 2800 kg

DESCRIPTION

Lightweight CE certified portable winch, mounted on an adaptor place.

The winch can be utilized in many applications; from utility masts, telecoms, marine, wind-turbine transition piece,

davits, stage and theatre rigging.

The adaptor plate can be affixed in a number of ways, dependant on the environment and industry; from ratchet

straps, M10 bolts, karabiners, to scaffold clamps. This makes for a truly universal and adaptable lifting solution.

Specifications

WARNING! Subjecting the winch to loads above the maximum working load can cause the winch to

fail or pull off the mounting plate suddenly, possibly resulting in severe injury or death.

Other manuals for 500

1

Table of contents

Other Harken Industrial Winch manuals

Popular Winch manuals by other brands

Comeup

Comeup DV-9 manual

Orvea

Orvea Italwinch 805 Installation and user manual

Prowinch

Prowinch PWJTHF300 user manual

Clas Ohlson

Clas Ohlson LD2000-A manual

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual