4.FEARTURES:

1. This machine is useful for cutting normal steel, steel pipe, and provides cutting angle at + 60°and

+45°by the swivel head.

2. A tooth selection chart was provided on the machine for cutting reference.

3. Variable speed control gives convenient selection of speeds. (This machine comes with a standard

2-speed motor. But can be purchased with a DC driven motor as an option.)

4. This machine is using manual cutting by pulling down the saw bow by hand. Start(press) button is

located at the handle of the saw bow. Motor stops when button was released.

5. Stability of the machine, plus working table height is 950 mm, conforming to human engineering.

6. The one-inch blade and carbide guide provide better result of the cutting surface and efficiency.

7. The one-piece casting and one time CNC processing provide better rigidity and precision of the

machine.

8. The one-piece and full coverage blade cover conforms to CE stipulation. Well coolant fluid

collection system provides clean and dry, and safety of the working area.

9. Chip pan underneath the working table prevents coolant fluid leaking and keep floor dry.

10. Coolant for cutting,, water : oil = 40 : 1 oil specification.

5.TRANSPORTATATION & INSTALLATION:

5-1.Unpacking

1. Transportation to desired location before unpacking, please use-lifting jack. (Fig. B)

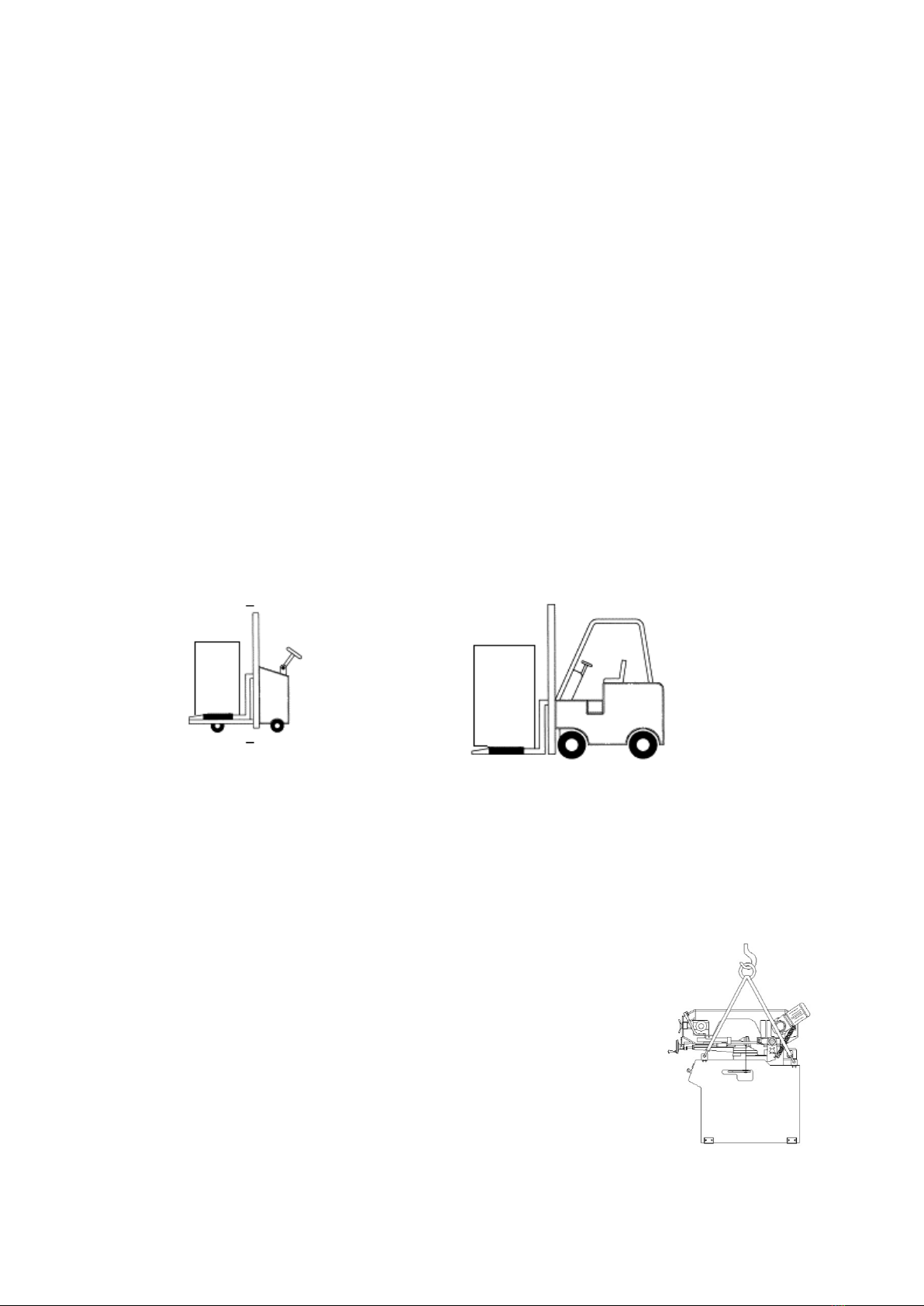

2. Transportation after unpacking, please use heavy duty fiber belt to lift up the machine.

ALLWAYS KEEP PROPER FOOTING & BALANCE WHILE MOVING THIS MACHINE.

5-2.TRANSPORTATION OF MACHINE:

As this machine weights 253kgs(556.6lbs) it is recommended that the machine be transported with help of

lifting jack.

Transportation Recommendation:

1. Tighten all locks before operation.

2. Always keep proper footing & balance while moving this machine, and only

use a heavy duty of fiber belt to lift the machine as per Fig. A.

3. TURN OFF the power before wiring & be sure machine is properly grounded.

Overload & circuit breaker are recommended for safety wiring.

4. Tighten 4 bolts to base holes after

machine is balanced.

5. Check carefully if the saw blade is running in counter-

clockwise direction if not, reverse the wiring per circuit diagram,

then repeat the running test.

6. Keep machine always out from sun, dust, wet, or raining area.

Fig, B