power King PK0311 Manual

Other power King Log Splitter manuals

power King

power King PK0322 Manual

power King

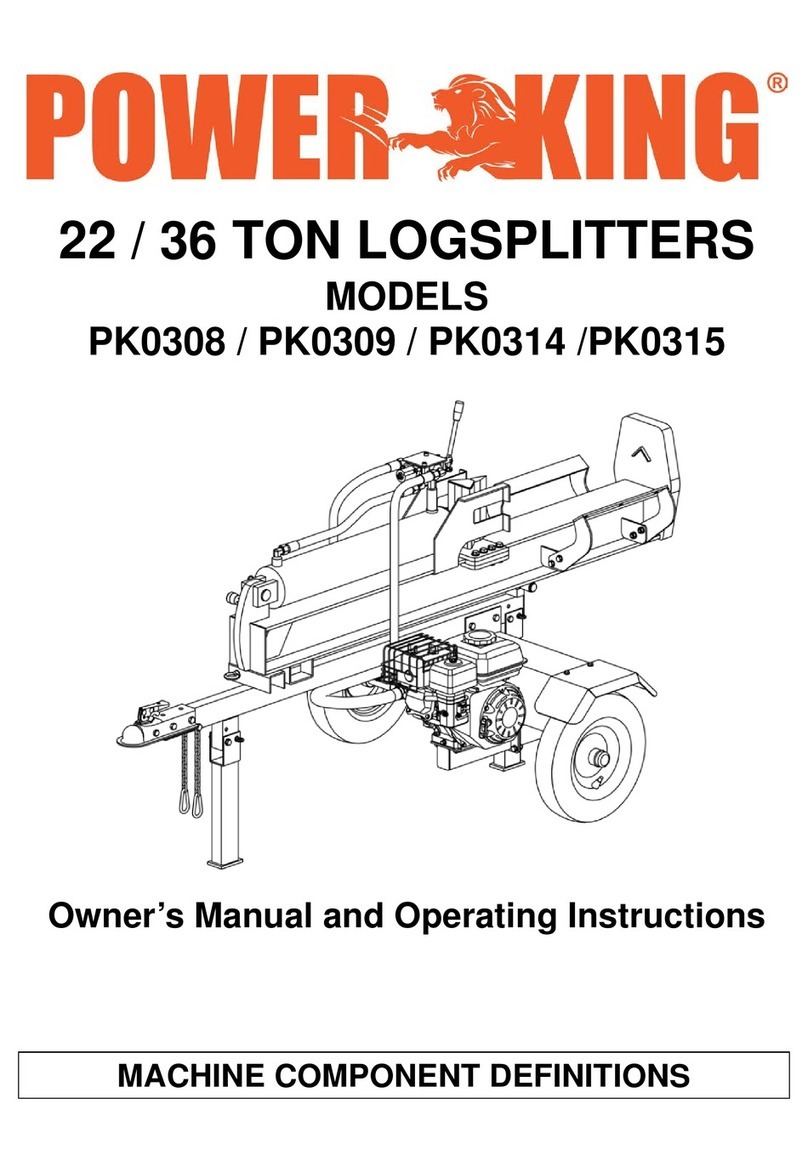

power King PK0308 Manual

power King

power King PK0322K Instruction Manual

power King

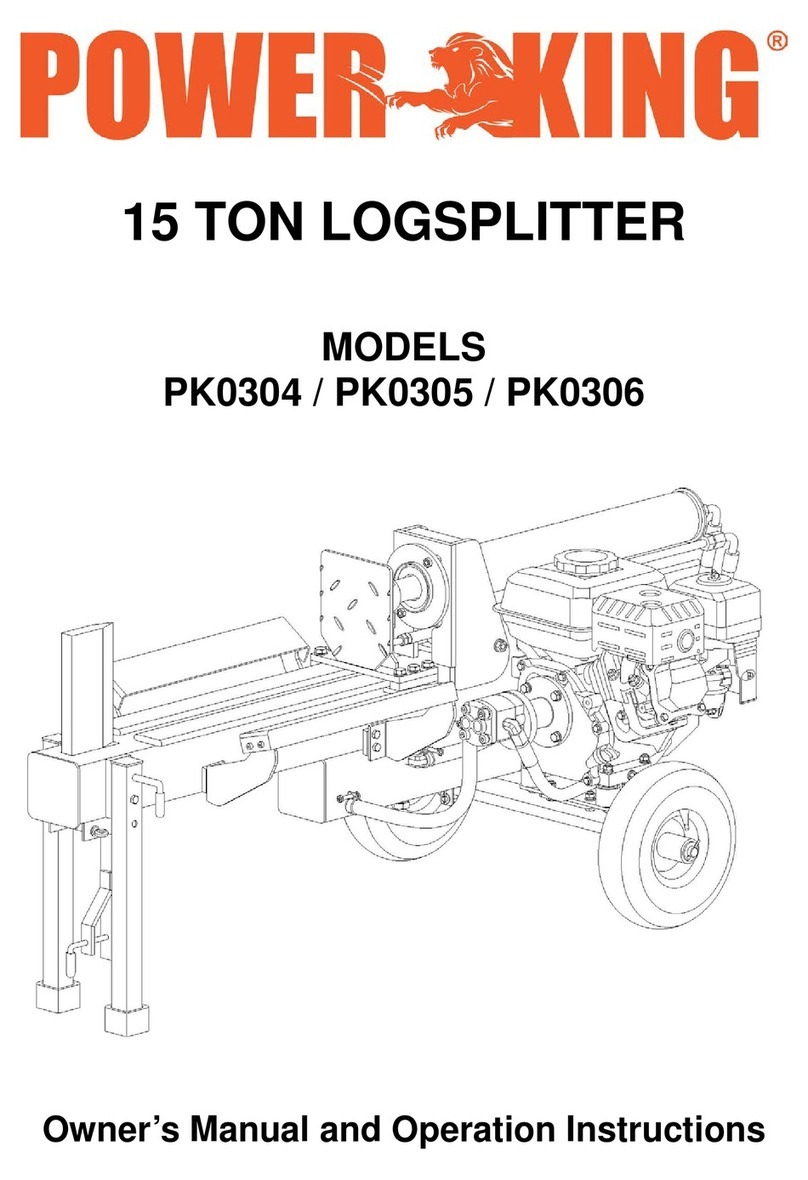

power King PK0304 System manual

power King

power King PK0324 User manual

power King

power King PK0342 User manual

power King

power King PK0311 User manual

power King

power King PK0303 User manual

Popular Log Splitter manuals by other brands

Scheppach

Scheppach OX 3-1000 Translation from the original instruction manual

Swisher

Swisher 21200 owner's manual

Elem Garden Technic

Elem Garden Technic FBHT65-22TCH instructions

Champion Power Equipment

Champion Power Equipment 90720 Owner's Manual and Operating Instructions

Villager

Villager LSP 12 T Original Operator's Manual

Boss Industrial

Boss Industrial ES5T20 owner's manual