OPERATION

4

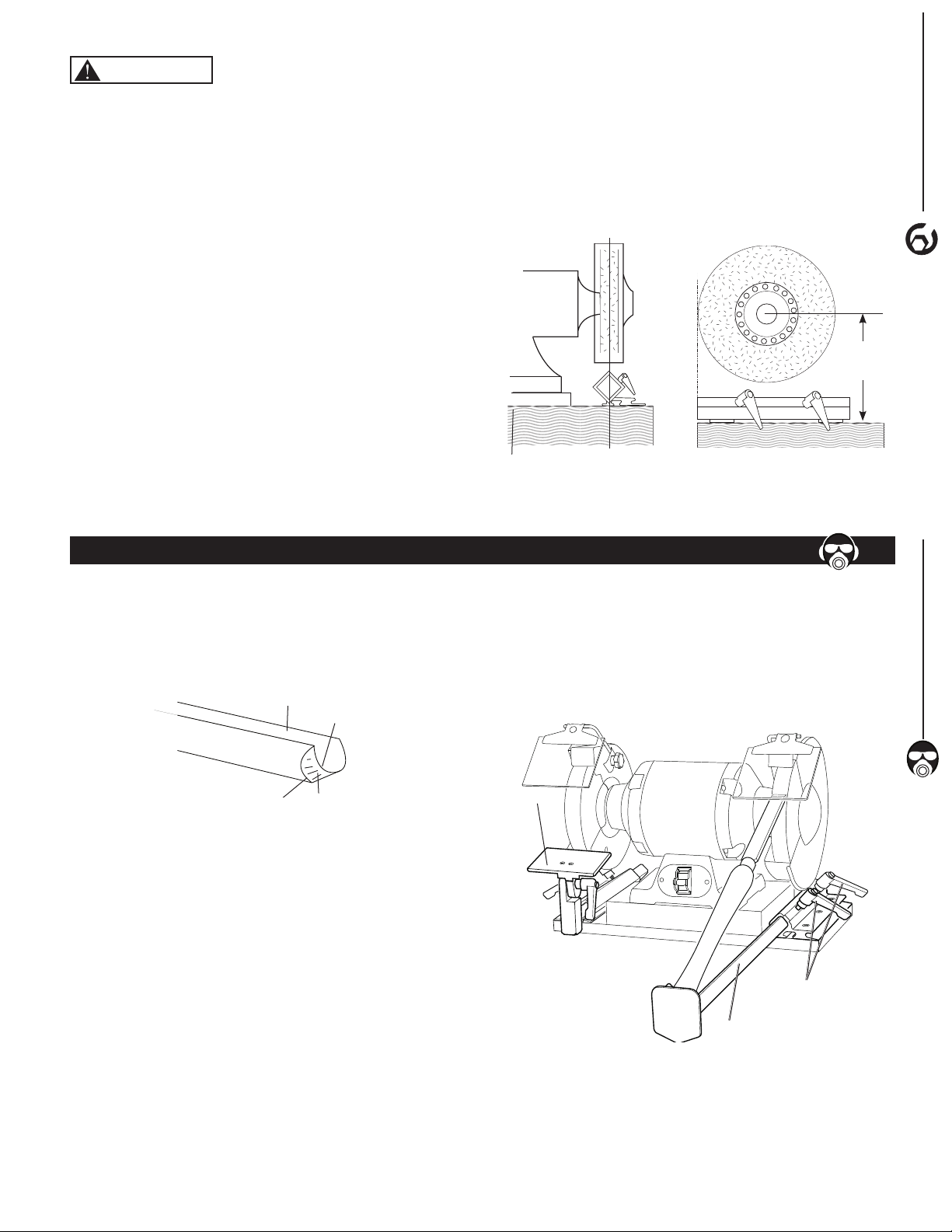

SKEW JIG OPERATION

3FGFSUP'JHVSFBOE

The skew jig saves time when sharpening skews. Using

the skew increases safety, creates a flat bevel, bevel and

cutting edge will be parallel, creates the same bevel every

time and there is a minimal material waste.

t 5VSOUIFHSJOEFSPGG

t 8JUI7"SNJTBTTFNCMFETMJEFUIFTLFXKJHPOUPUIF

V arm pocket and secure with locking knob.

t 3FTUUIFIBOEMFPGUIFUPPMJOPOFPGUIFTLFXKJHQPDLFU

depending on desired angle.

t 4MJEFUIF7"SNJOBOEPVUVOUJMUIFFYJTUJOHCFWFMNFFUT

the wheel.

t -PDLUIF7"SNJOQMBDF

t -JGUUPPMGSPNXIFFMBOEUVSOUIFHSJOEFSPO

t -JGUUIFUPPMPGGUIFXIFFMBOEDIFDLUIFHSJOENBSLTPO

the bevel.

- If the grind marks are even on the whole bevel, then

the V Arm is adjusted properly.

- If the grind marks are just on the cutting edge, move

the V Arm in.

- If the grind marks are on the heel of the tool, away

from the cutting edge, move the V Arm out.

TIP: Coloring the existing bevel with a black felt tip marker

allows the new grinding marks to be seen.

t 5PVDIUIFCFWFMUPUIFXIFFM6TJOHMJHIUQSFTTVSFTMJEF

the tool back and forth with a small sideway motion.

t 5VSOUIFUPPMPWFSPGUFOTIBSQFOJOHCPUITJEFTPGUIF

skew.

TIP: Applying pressure to the side with the short point

creates more skew. Applying pressure to the long point

reduces skew.

Figure 9

Base

V Arm

Jig Locking Levers

Skew

Skew Jig

Locking

Knob

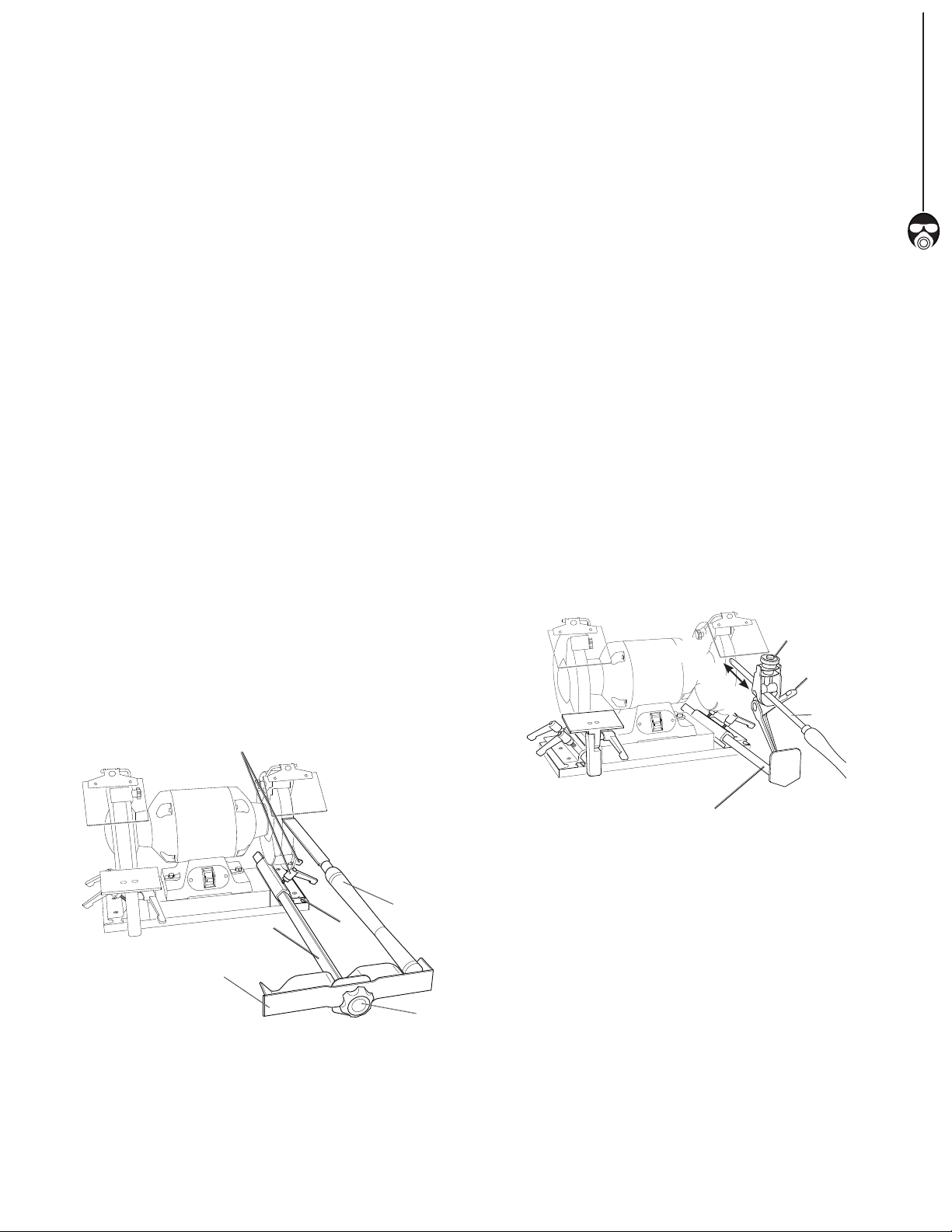

VERSA-GRIND OPERATION

Refer to Figure 10

Consistently achieve the fingernail grind, bowl gouge

grind and side or Irish grind by using the Versa-Grind

attachment.

t 5VSOUIFHSJOEFSPGG

t *OTFSUUIFUPPMJOUPUIF7FSTB(SJOE5JHIUFOMPDLJOH

knob.

NOTE:5IFUPPMTIPVMEQSPUSVEFNNUP

create the best results. This measurement should be the

same each time the tool is ground. Use a wood block

with a hole drilled to the desired depth to save time.

t "EKVTUUIF7FSTB(SJOEBSNUPEFTJSFEBOHMF

NOTE: Adjusting the arm with the arm adjustment knob

will alter the angle to be ground.

t 8JUIUIF7"SNBTTFNCMFESFTUUIFBSNPGUIF7FSTB

Grind onto the V arm pocket.

t 4MJEFUIF7"SNJOBOEPVUVOUJMUIFEFTJSFEBOHMFNFFUT

the wheel.

t -PDLUIF7"SNJOQMBDF

t -JGUUPPMGSPNXIFFMBOEUVSOUIFHSJOEFSPO

t 8JUIPOFIBOEFOTVSFUIFUIF7FSTB(SJOEBSNSFTUJO

the bottom of the V arm, use the other hand to control

the sweep of the Versa-Grind. Let the weight of the tool

do the work.

NOTE: Frequently dip the tool in water to keep it cool.

Figure 10

V Arm

Locking

Knob

Tool

Arm

Adjusting

Knob

NN